Radius spilt offset screen, 36 radius offset keypad, Adjusting the c axis – Darex XPS-16 Operating Instructions User Manual

Page 36

36

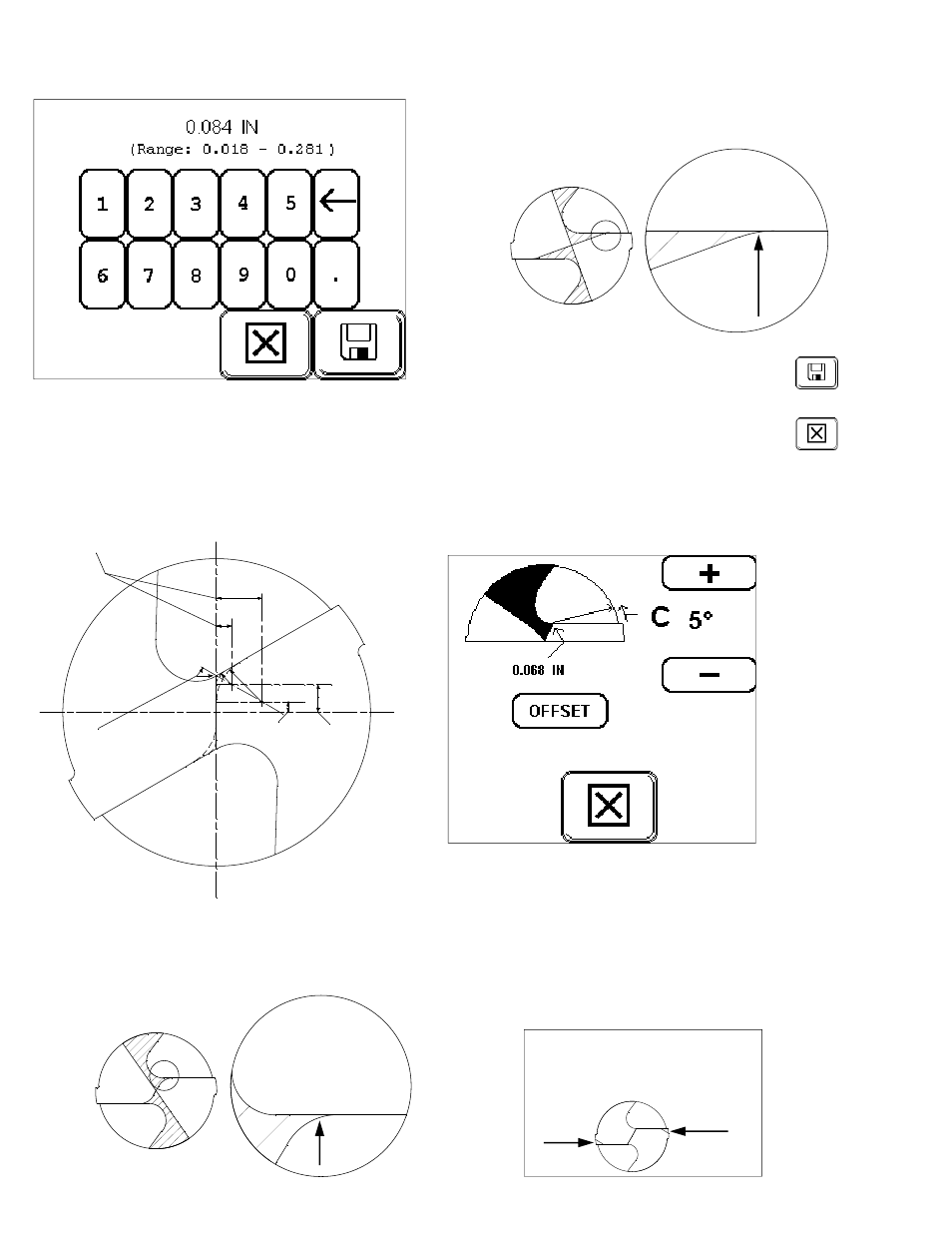

Radius Offset Keypad

•

Type in the offset amount. An offset amount

of.001 will produce the largest possible radius.

As your offset gets larger the radius will be-

come smaller.

NOTE: It may be more difficult to achieve a

larger radius on drills with split angles

greater than 120°.

The greater split angle, the less apparent

the radius. See view B

•

Touch the “SAVE” button to store the

“New” information and transfer you back

to the previous screen.

•

Selecting “CANCEL” will delete any

unsaved data, retrieving the most re-

cently saved information, transferring you

back to the previous screen.

Adjusting The C axis

•

Adjust the stopping point of the C axis. The

factory default is 5°. This will stop the oppo-

site cutting edge of the drill 5° from the grind-

ing wheel. In most cases, adjustment of the C

axis will not be necessary. Adjustment is nec-

essary only if the C axis rotates too far into

the grinding wheel nicking the cutting edge of

the drill.

Cu

ttin

g e

dg

e

Centerline of radius tangent to

chisle line and cutting edge.

from center

from center

Centerline of radius centers

bisect the chisle angle of the

chisleline and cutting edge.

Diagram of radius split showing offset variable. Larger offset creates smaller radius, smaller offset

creates larger radius. Offset can be from 1% - 50% of web thickness dimension. Dotted lines

indicate large and small radius.

Chisleline

Large offset

C

h

is

le

lin

e

Small offset

View

A

120° radius Split

A

B

View

B

160° radius Split

If drill rotates to far, a negative

rake is noticable on the outside

corners of cutting lip

Radius Spilt Offset Screen

If drill rotates too far, a negative rake

is noticeable on the outside corners of

cutting lip

120° Radius Split

160° Radius Split