Hone selector, Grind selector, Touch screen details – Darex XPS-16 Operating Instructions User Manual

Page 21

21

edge.

Refer to page 39

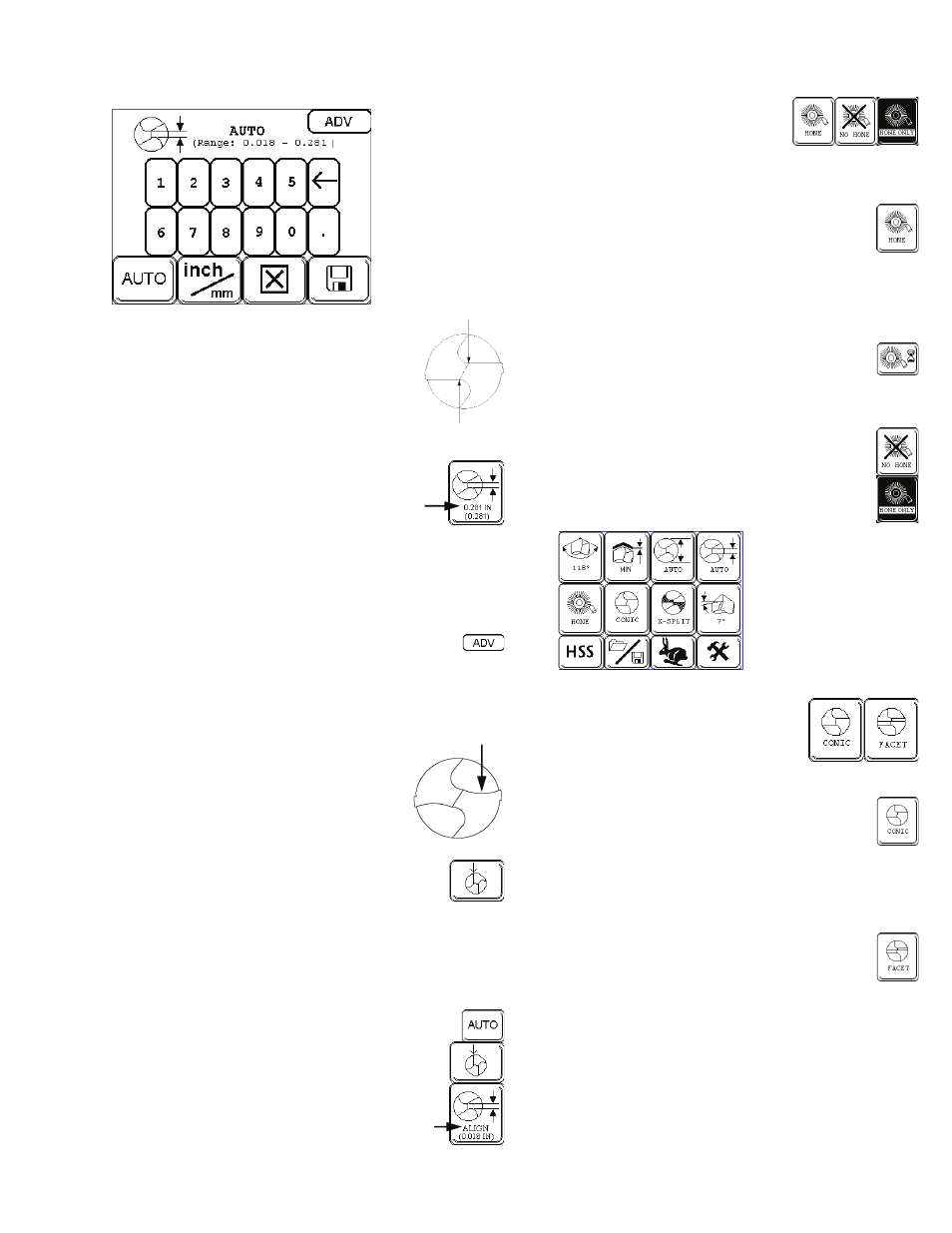

Web Detection Screen

•

To manually input the web thick-

ness, measure thickness of the web

of the drill. Measure web thickness

across two points of the chisel line

with calipers

•

Type in web thickness, including

decimal point. The web thickness,

manually entered, will appear on the

Main Screen “WEB THICKNESS” Selec-

tor button and will disable the auto

mode.

NOTE: If you enter a number outside the ca-

pability range of the sharpener, the setting

will default to the nearest MIN/MAX web

thickness for that specific diameter of drill.

Cutting Edge Advance Button

•

Located within the Web Detection Screen is

the “ADVANCE” button. Using this feature may

be necessary when the drills cutting edge

aligns incorrectly. To compensate for incorrect

cutting edge alignment, you can

manually advance the cutting

edge using the “ADVANCE” but-

ton . This may be necessary when

sharpening drills with a hooked

cutting edge.

Refer to page 39

Manual Align Button

•

This feature allows you to bypass the

fiber optic sensor alignment process. Measure

and enter the web thickness of the drill, if you

do not enter the web thickness, the value will

default to the minimum web thickness value

within that range. If the diameter detec-

tion is in Auto, the web thickness value

will default to the minimum once the

diameter has been detected. Touch the

Auto button in web detection, the Man-

ual Align button will come up. Touch

Save. Align and the web thickness will

appear in the icon on the main page.

Insert the drill with the cutting edge at 12

o’clock. Tighten chuck & press cycle start.

Hone Selector

•

With each touch of the icon

you will bring up the next

honing option.

You have 3

options: Hone, No Hone or Hone Only

NOTE: Factory default is “NO HONE”.

•

Select “HONE” when sharpening carbide

drills. Honing the carbide cutting edge

greatly influences tool life and the accu-

racy of the finished surface. The length

of hone time is adjustable. The longer the

drills cutting edge remains in the honing cycle,

the larger the radius produced on the cutting

edge.

Refer to page 53.

Go to the Hone

Timing Adjustment Screen in the Tools,

Maintenance and Offset screen to make

honing time adjustments.

Refer to page 31

•

Select “NO HONE” when sharpening

High Speed Steel or Cobalt drills.

•

Select “HONE ONLY” when only honing

drills. Grinding and Splitting will be dis-

abled.

Grind Selector

•

With each touch of the button

you will bring up the next point

style option. There are 2 point

style options: Conic or Facet

NOTE: Factory default is “CONIC”.

•

“CONIC” – This radial/cone style grind is

known as a conventional point and used

through out the machine tool industry. A lip

clearance of 12° to 15° at the periphery of the

drill, increasing constantly toward the center,

is considered standard for the average

class of work.

•

“FACET” – Multi faceted drill points

consist of a separate cutting lip (primary)

and secondary heel clearance (relief) facet.

The multi-faceted drill requires 150% less

thrust and produces 70% less heat than a

conventional drill.

•

The width of the primary facet is determined

by the thickness of the drills web and cannot

be changed. If your drill has a thin web, we do

not recommend a facet point style. The width

Touch Screen Details