Split point selector, Relief screen selector, Touch screen details – Darex XPS-16 Operating Instructions User Manual

Page 22

22

of the primary

facet produced

may be very

thin. The

thicker the

web of your

drill, the wider

the primary facet will appear.

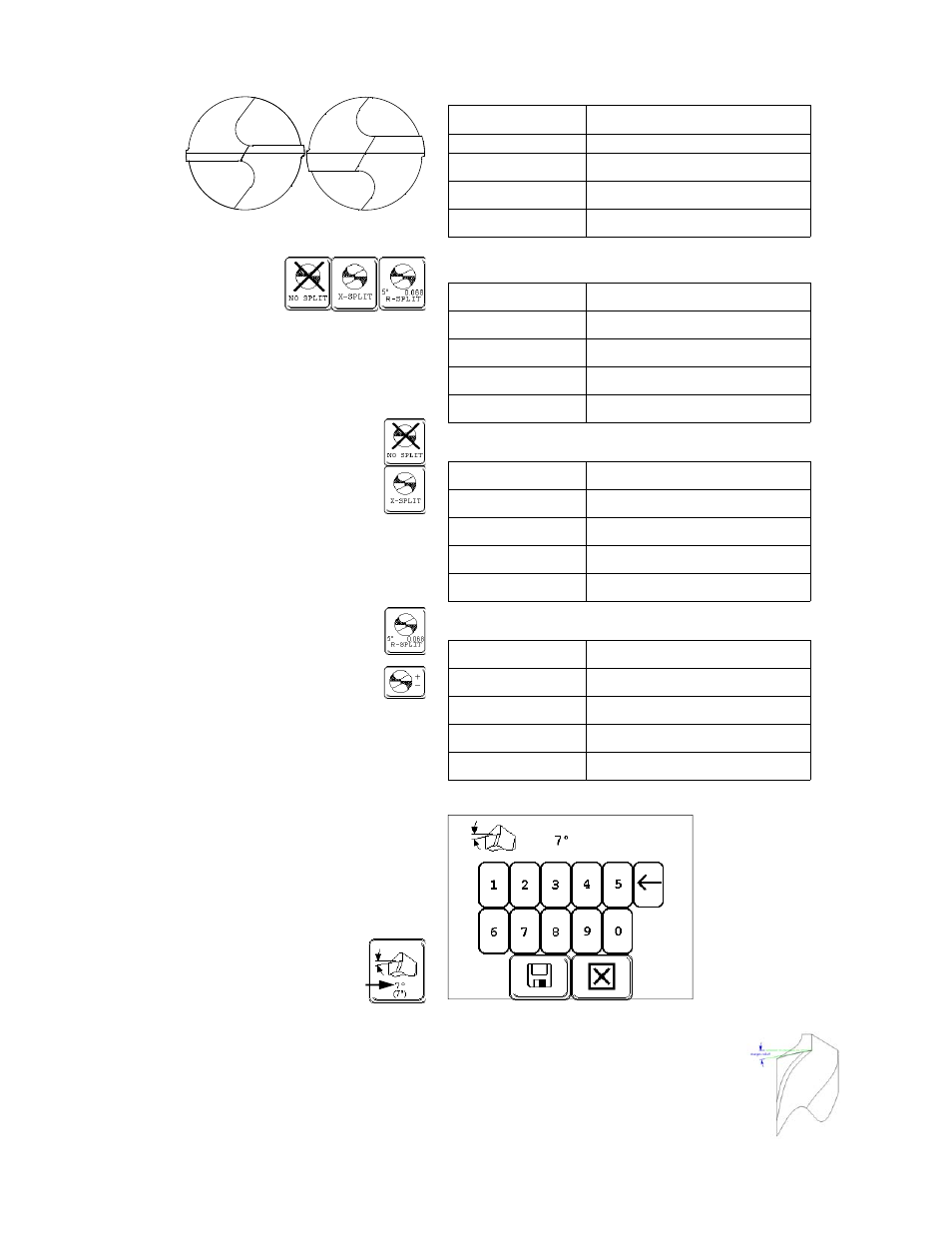

Split Point Selector

•

With each touch of the icon

you will bring up the next

split style option. There are

3 split point options: No Split, X- split

(Standard) and R- Split. (Radius) The XPS-16

will produce a chisel angle ground to

approximately 130°.

NOTE: Factory default is “SPLIT”.

•

“NO SPLIT” – Select when reproducing a

non-split drill point style.

•

“X-SPLIT” – 4° split point rake angle is

created, producing a drill with a self-

centering point. Its advantages are the

ability to reduce thrust and eliminate walking

at the drill point. This is a distinct advantage

where drilling bushings/fixtures are not used.

•

“R-SPLIT” – The R-split selection is not

an option until the web thickness value

has been manually entered. Changing

the amount of radius and rotation is

adjustable. This is done in the Split Point

Offset screen .

Refer to information on

page 35

for details.

•

An R-split will produce a drill with a self-

centering point as well as act as a chip

breaker producing smaller chips, which can

readily be ejected. The radius will assist the

flow of chips and reduce chip impaction at the

tip of the drill.

Relief Screen Selector

•

Select lip relief clearance from 5° to

18° +/-2°. The diameter and the point

angle will determine the degrees of

possible relief. See tables below.

NOTE: The degree of relief entered, will ap-

pear on the relief selector button on the

main screen menu.

Facet with thin web Facet with thick web

POINT ANGLE 118 – 124

POINT ANGLE 125-134

POINT ANGLE 135-144

POINT ANGLE 145-150

Relief Screen

•

Type in desired margin relief.

NOTE: If you enter a degree of

relief outside the capability range

of the sharpener or the drill di-

ameter/point angle, the setting

will default to the nearest MIN/

MAX relief amount for that spe-

cific diameter/point angle of drill.

DIAMETER

DEGREES OF RELIEF

.118 – .245

8 – 18

.245 – .370

6 – 16

.370 – .495

5 – 14

.495 – .625

5 – 12

DIAMETER

DEGREES OF RELIEF

.118 – .245

8 – 16

.245 – .370

6 – 14

.370 – .495

5 – 12

.495 – .625

5 – 10

DIAMETER

DEGREES OF RELIEF

.118 – .245

8 –15

.245 – .370

6 – 13

.370 – .495

5 – 11

.495 – .625

5 – 9

DIAMETER

DEGREES OF RELIEF

.118 – .245

8 – 14

.245 – .370

6 – 12

.370 – .495

5 – 10

.495 – .625

5 – 8

Touch Screen Details