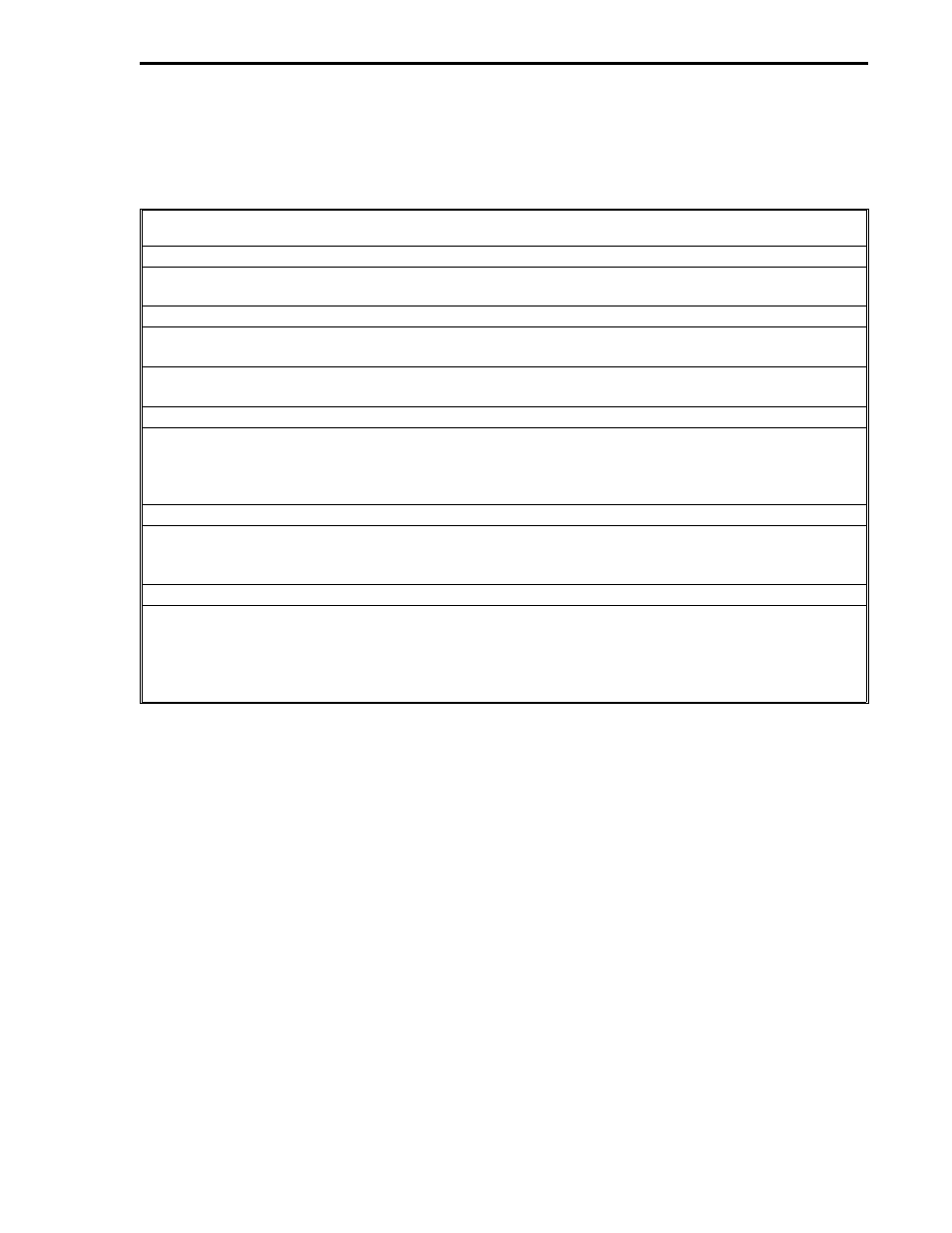

Table 6-11. modbus slave fault isolation aids – Micromod Micro-DCI: 53MC5000 PLC AND PRINTER INTERFACES User Manual

Page 83

6.5.5 PCS MODBUS SLAVE FAULT ISOLATION AIDS

Table 6-11 summarizes information provided in this section and other sections of the book that can

be referenced as an aid to fault isolation.

Table 6-11. Modbus Slave Fault Isolation Aids

Environmental/Power

See Table 1-1 for RS-232/485 ITB environmental and power specifications; see 53MC5000 PCS

Instruction Bulletin for PCS environmental and power specifications.

PCS Setup Errors

Setup Error 10 (Table 6-9) - Set Scan Time to non-zero value. PCS APB Setup bytes (Table 6-

8) - Should agree with the communication setup of the master device system.

Scan Overrun Counter (Table 6-9 and Section 3.7) - Expand Scan Time if the count increases at

an unacceptable rate.

Communications

Proper cable fabrication between the RS-232/485 ITB and the master device (Figures 6-2 and 6-

3). Communication Error and Error Count (Table 6-10) - Execute the Diagnostic command

(Function code = 8) from the master device to the PCS Modbus slave to test the communications

link.

Possible PLC Problems

Reference the appropriate PLC documentation for the required action.

Exception Response Codes 1-3 (Table 6-10) - Check Function, Data Address, and Data Values in

master device commands being sent to PCS Modbus slave.

RS-232/485 ITB Activity Indicators

Inactivity from the XMT (CR13) and RCV (CR14) LEDs could indicate line problems, a hung

device, a misconfiguration between the PCS and master device resulting from manual database

alterations made at either device, or just no DDI channel activity. Active indicators on the RS-

232/485 ITB do not necessarily mean error free operation, e.g., repeated PCS-master device

transactions attempted with timeout errors.

Section 6. MODBUS RTU Mode

MODBUS2

6-19