10 fault isolation aids, Table 5-5. fault isolation aids – Micromod Micro-DCI: 53MC5000 PLC AND PRINTER INTERFACES User Manual

Page 63

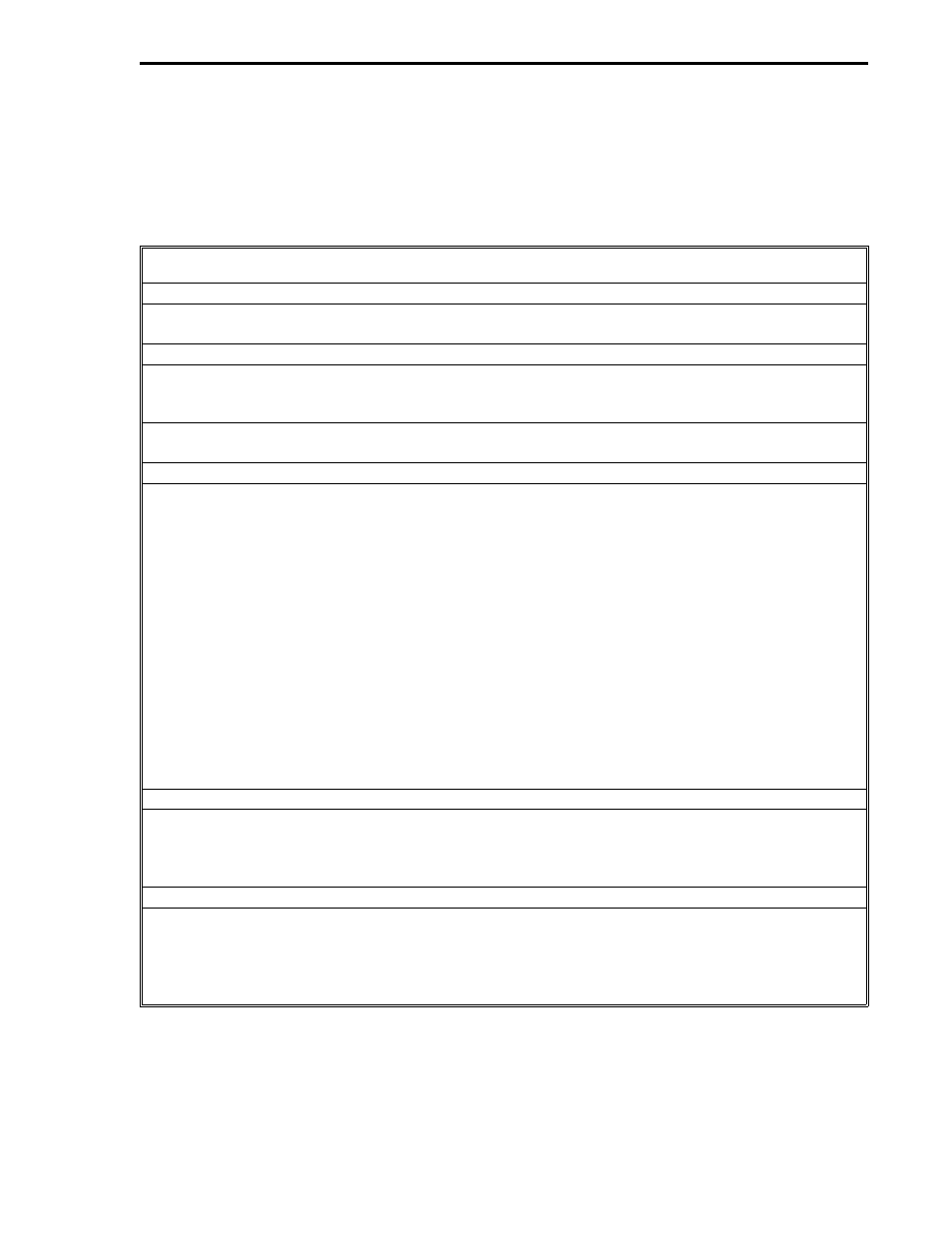

5.10 FAULT ISOLATION AIDS

Table 5-5 summarizes information provided in this section and other sections of the book that can

be referenced as an aid to fault isolation.

Table 5-5. Fault Isolation Aids

Environmental/Power

See Table 1-1 for RS-232/485 ITB environmental and power specifications; see 53MC5000 PCS

Instruction Bulletin for PCS environmental and power specifications.

PCS Setup Errors

PCS Setup Error 2 (Table 5-2) - Bad B Value. Setup Error 10 - Scan Time at 0. PCS APB Setup

bytes (Table 5-1) - Baud Rate and Set-Up should agree with the communication setup of the

OPTOMUX board(s).

Scan Overrun Counter (Table 5-2 and Section 3.7) - Expand Scan Time if the count

increases at an unacceptable rate.

Communications

Communications errors that occur during the Initialization sequence cause the PCS to cycle in the

Initialization sequence until the cause of the error is rectified. For checksum (Block Check

Character [BCC]) and bad message errors, the PCS does not use the data but will try again, for

example: if a checksum error occurs during the read, the PCS will perform the write in that Scan

Time and attempt another read the next Scan Time. If there are five consecutive read errors or

five consecutive write errors, the PCS will enter the Initialization sequence.

See Table 5-2, Communication Error Code (B682, B658) for error codes.

See Table 5-2, Communications Error Count (B683, B659) for the running total of

communications errors.

See Table 5-2, First Bad Board Address (B687, B663) for the address of the first OPTOMUX

board accessed when the error occurred.

Reconfigure to a smaller system to eliminate the suspect OPTOMUX board.

Check custom cable between the RS-232/485 ITB and the OPTOMUX board.

(See Figure 5-6).

Possible OPTO-22 Problems

See Table 5-2, Communications Error Code (B682, B658) for OPTOMUX error codes 240-247

(00-07 in OPTOMUX documentation). Ensure OPTOMUX brain board jumper settings are

correct. Brain board may be mis-wired or failing. Verify with OPTOMUX documentation.

RS-232/485 ITB Activity Indicators

Inactivity from the XMT (CR13) and RCV (CR14) LEDs could indicate line problems, a hung

device, a misconfiguration between the PCS and PLC resulting from manual database alterations

made at either device, or just no DDI channel activity. (Active indicators on the RS-232/485 ITB

do not necessarily mean error free operation, e.g., repeated PCS-OPTOMUX board transactions

attempted with timeout errors.)

Section 5. OPTO 22 Mode

OPTO

5-17