Gf100 series – Brooks Instrument GF126 User Manual

Page 9

1-3

GF100 Series

Installation and Operation Manual

X-TMF-GF100-Series-MFC-eng

Part Number: 541B137AAG

March, 2013

Section 1 Introduction

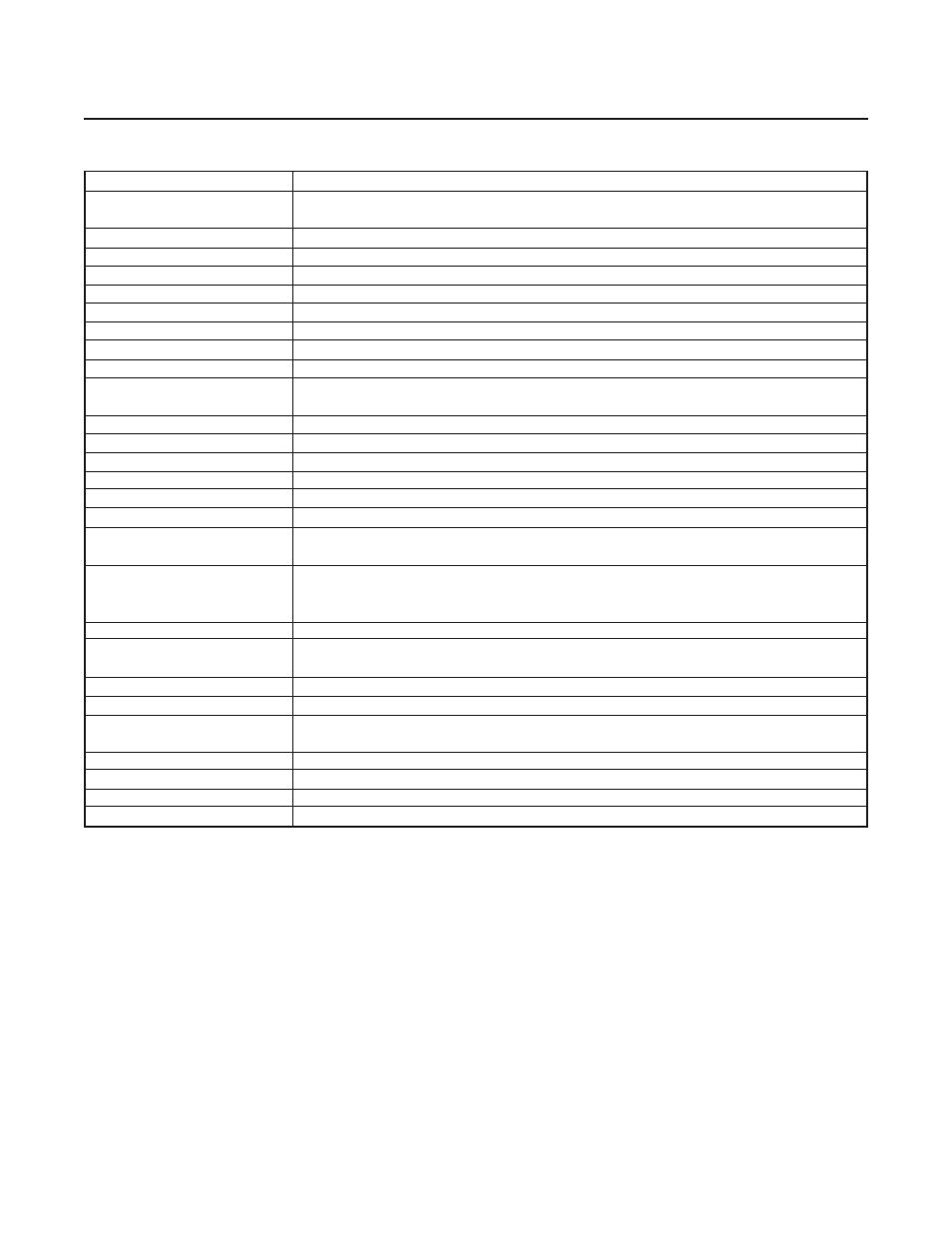

Table 1-1 Industry Standard References

Reference Number

Reference Description

MIL-STD-810

Method 514.4, Category 1, Transportation Requirement

Method 516.4, Procedure 1, Functional Shock Test Requirement

SEMI E12

Standard temperature and pressure

SEMI E16

Guideline for determining and describing MFC leak rates

SEMI E17

Guideline for MFC transient characteristics tests

SEMI E18

Guideline for temperature specifications of the MFC

SEMI E27

Standard for MFC and MFM linearity

SEMI E28

Guideline for pressure specifications for the MFC

SEMI E52

Practice for referencing gases used in digital MFCs

SEMI E54

Sensor actuator network connections for DeviceNet

SEMI E56

Test method for detemining accuracy, linearity, repeatability, short-term

reproducibility, hystereses of thermal MFCs

SEMI E66

Test method for determining particle contribution by MFCs

SEMI E67

Test method for determining reliabilty of MFCs

SEMI E68

Test method for determining warm-up time of MFCs

SEMI E69

Test method for reproducibilty and zero drift for thermal MFCs

SEMI E80

Test method for determining attitude sensitivity of MFCs

SEMI E16-90

Guidelines for determining and describing mass flow controllers leak rates

SEMI F19

Specification for the finish of the wetted surface of electro polished

216L stainless steel components

SEMI F20

Specifications for 316L stainless steel bar, extruded shapes, plate, and

investment castings for components used in ultra-high purity semi

manufacturing applications

SEMI F36

Guide for dimensions and connections of gas distribution components

SEMI F37

Method for determination of surface roughness parameters for gas

distribution system components

SEMI F44

Guideline for standardization of machined stainless steel weld fittings

SEMI F45

Guideline for standardization of machined stainless steel reducing fittings

SEMI F47

Specifications for semiconductor processing equipment

voltage sag immunity

SEMI S2

Environmental, Health and Safety Guidelines

SEMI S9

Dielectric testing

SEMI S10

Risk assessment

SEMI S12

Decontamination of fielded products