Gf100 series, Warning – Brooks Instrument GF126 User Manual

Page 28

2-8

GF100 Series

Installation and Operation Manual

X-TMF-GF100-Series-MFC-eng

Part Number: 541B137AAG

March, 2013

Section 2 Installation

2-13 Perform a Leak Test

WARNING

!

It is critical to leak test the gas supply lines and GF100 Series connections

before turning on the process gas supply after any new installation. Check

for leaks using a helium leak detector or any other appropriate leak test

method. Follow leak test specifications as defined by integrator.

2-14 Zeroing Setup Process

The following steps are required before the GF100 Series is zeroed.

1. Make sure that the GF100 Series has been installed inside the

equipment (panel) for at least four hours and powered up at least one

hour prior to zeroing. This insures that the GF100 Series is in its "use

attitude" and is operating at normal temperature. If the GF100 Series is

subjected to a vacuum purge for more than one minute, turn off the

GF100 Series (ie., provide a zero setpoint) for a time period of twice the

vacuum purge time.

2. Refer to Figure 2-1. Open the upstream shut-off valve (5) and close the

downstream shut-off valve (7). This eliminates a pressure drop across

the GF100 Series and subsequent leakage from the PID control valve

inside the GF100 Series.

3. Provide a 100% setpoint to the GF100 Series for no longer than 60

seconds. This equalizes the pressure across the PID control valve.

4. Refer to Figure 2-1. Close the upstream shut-off valve (5) to prevent any

pressure effects from the regulator (3).

5. Close the GF100 Series and wait two minutes.

6. Read the output signal of the GF100 Series. This output signal is the

initial flow in percent of full scale. The output signal should be 0.0 (±

0.1%). If the output signal is too high, re-zero the GF100 Series as

described in Section 2-15.

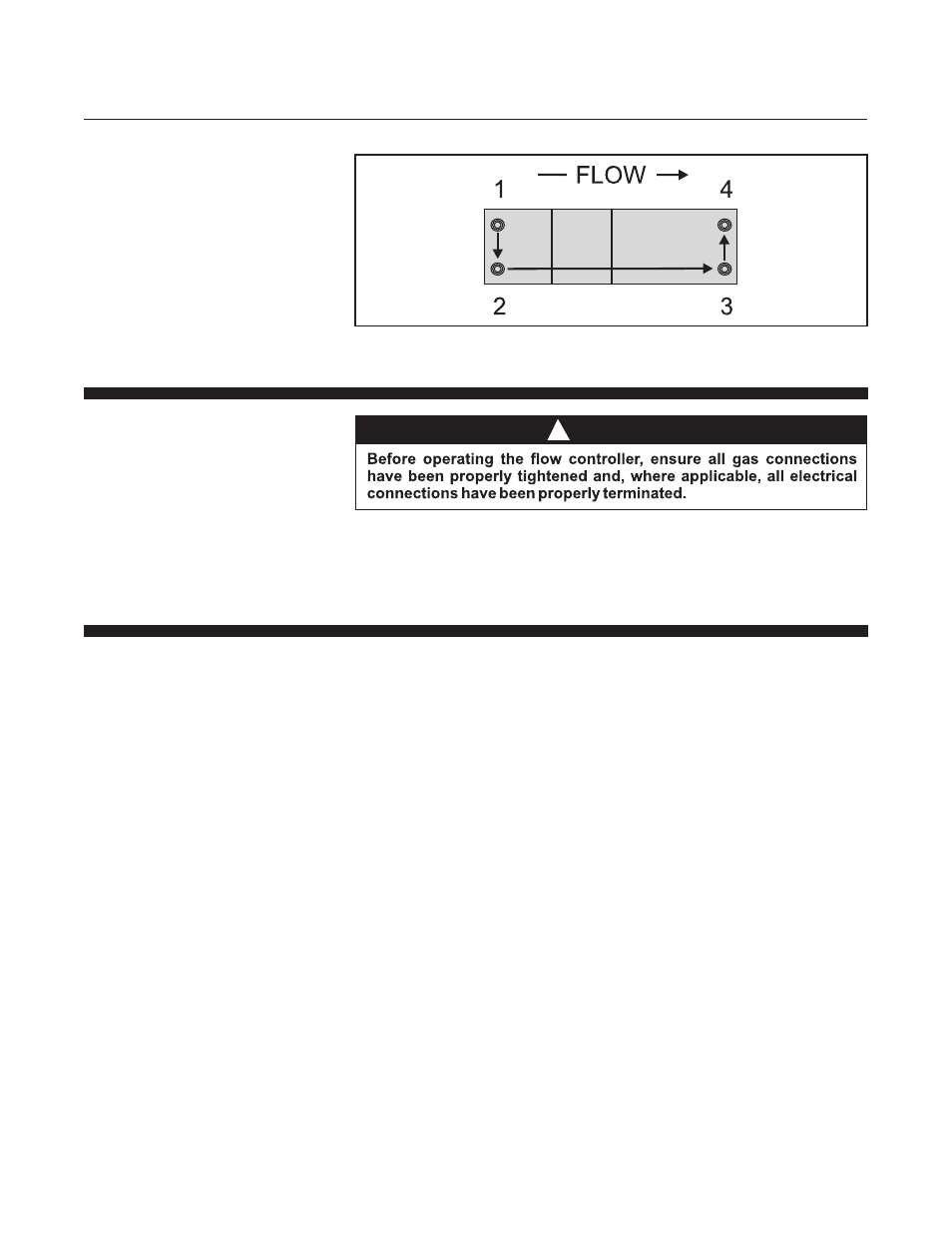

Figure 2-5 Mounting Screws Torque Pattern