Gf100 series – Brooks Instrument GF126 User Manual

Page 22

2-2

GF100 Series

Installation and Operation Manual

X-TMF-GF100-Series-MFC-eng

Part Number: 541B137AAG

March, 2013

Section 2 Installation

2-4 Return Shipment

Prior to returning any device to the factory, visit the Brooks web site

(www.BrooksInstrument.com) for a Return Materials Authorization Number

(RMA#), or contact one of the locations provided on p. 2-1.

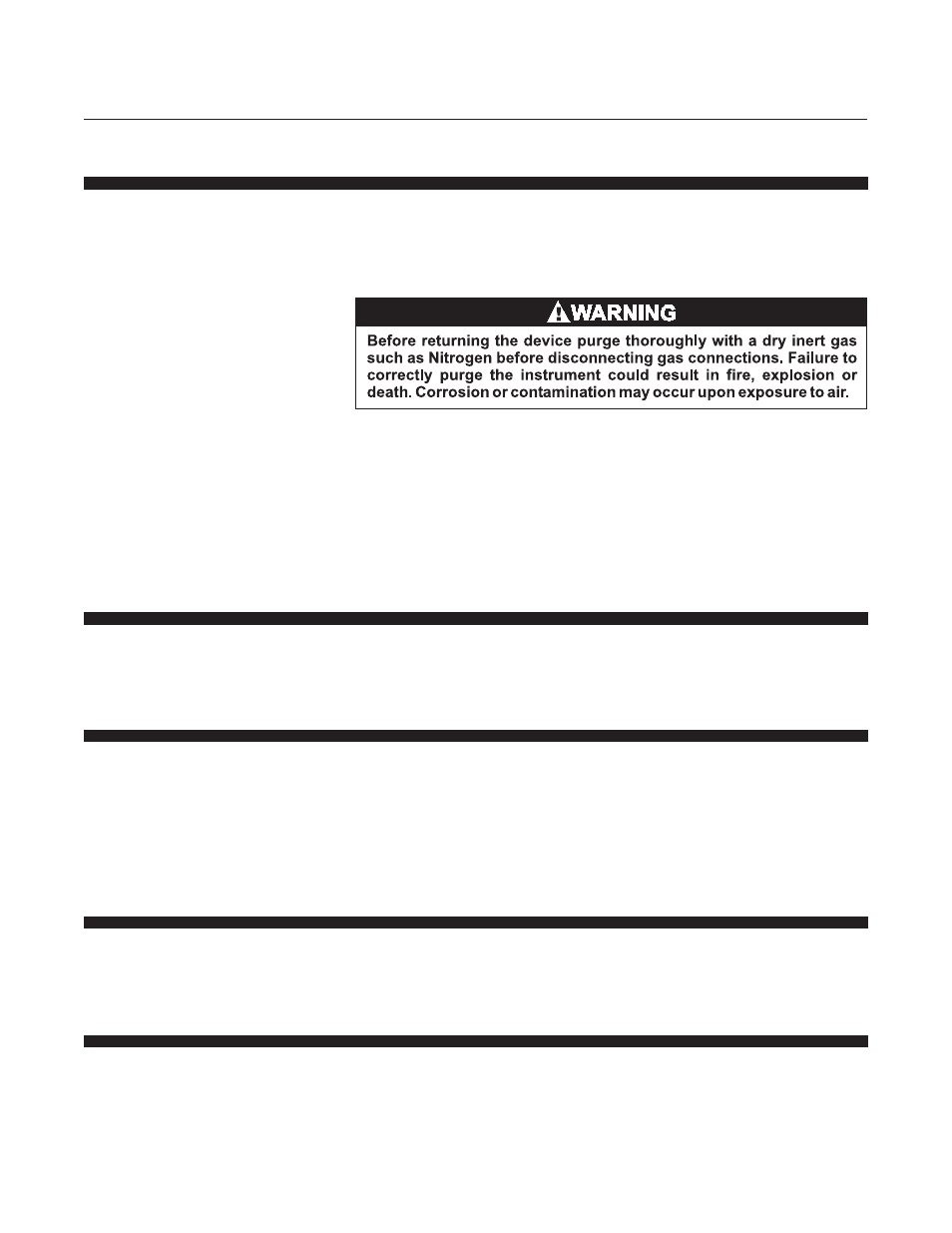

Prior to returning the device, it must be purged in accordance with the

following:

All flow devices returned to Brooks require completion of Form RPR003-1,

Brooks Instrument Decontamination Statement, along with a Material

Safety Data Sheet (MSDS) for the fluid(s) used in the instrument. Failure

to provide this information will delay processing by Brooks personnel.

Copies of these forms can be downloaded from the Brooks website

(www.BrooksInstrument.com) or are available from any of the Brooks

Instrument locations provided on p. 2-1.

2-5 Transit Precautions

To safeguard against damage during transit, transport the device to the

installation site in the same container used for transportation from the

factory, if circumstances permit.

2-6 Removal from Storage

Upon removal of the device from storage, a visual inspection should be

conducted to verify its "as-received" condition. If the device has been

subject to storage conditions in excess of those recommended (refer to

"2-3 Recommended Storage Practice" on p. 2-1), it should be subjected

to a pneumatic pressure test in accordance with applicable vessel codes.

To maintain a devices ultraclean integrity, this service should be

performed by the factory or one of the certified service centers.

2-7 Gas Connections

Prior to installation, ensure that all piping is clean and free from

obstructions. Install piping in such a manner that permits easy access to

the device if removal becomes necessary.

2-8 In-Line Filter

It is recommended that an in-line filter be installed upstream from the

device to prevent the possibility of any foreign material entering the flow

sensor or control valve. The filtering element should be replaced

periodically or ultrasonically cleaned.