Gf100 series – Brooks Instrument GF126 User Manual

Page 29

2-9

GF100 Series

Installation and Operation Manual

X-TMF-GF100-Series-MFC-eng

Part Number: 541B137AAG

March, 2013

Section 2 Installation

2-15 Zeroing the GF100 Series

Many high density gases exhibit slight changes in zero output as a function

of inlet pressure. Gases such as tungsten hexafluoride and many

fluorocarbons are especially sensitive to this problem. Since inlet pressure

is a potential source for zero errors, the pressure transducer on each

GF100 Series should be correctly set to zero after installation. The zeroing

process is performed from the backlight LCD display on top of the GF100

Series.

OEM tools using a microprocessor or computer for operating the GF100

Series should sequence the GF100 Series off between processes. To

accomplish this, simply provide a zero set point. The GF100 Series will shut

off automatically.

Shut-off valves, whether upstream or downstream from the GF100 Series,

should be programmed to turn on before the GF100 Series is turned on and

turned off after the GF100 Series is turned off.

2-15-1 Zeroing the GF100 Series Pressure Transducer from the LCD Display Panel

1. Place the GF100 Series under a strong vacuum with the GF100

Series set to 100% set point. Make sure that upstream valve is

closed and the downstream valve is open. Allow time for the

upstream pressure to bleed off.

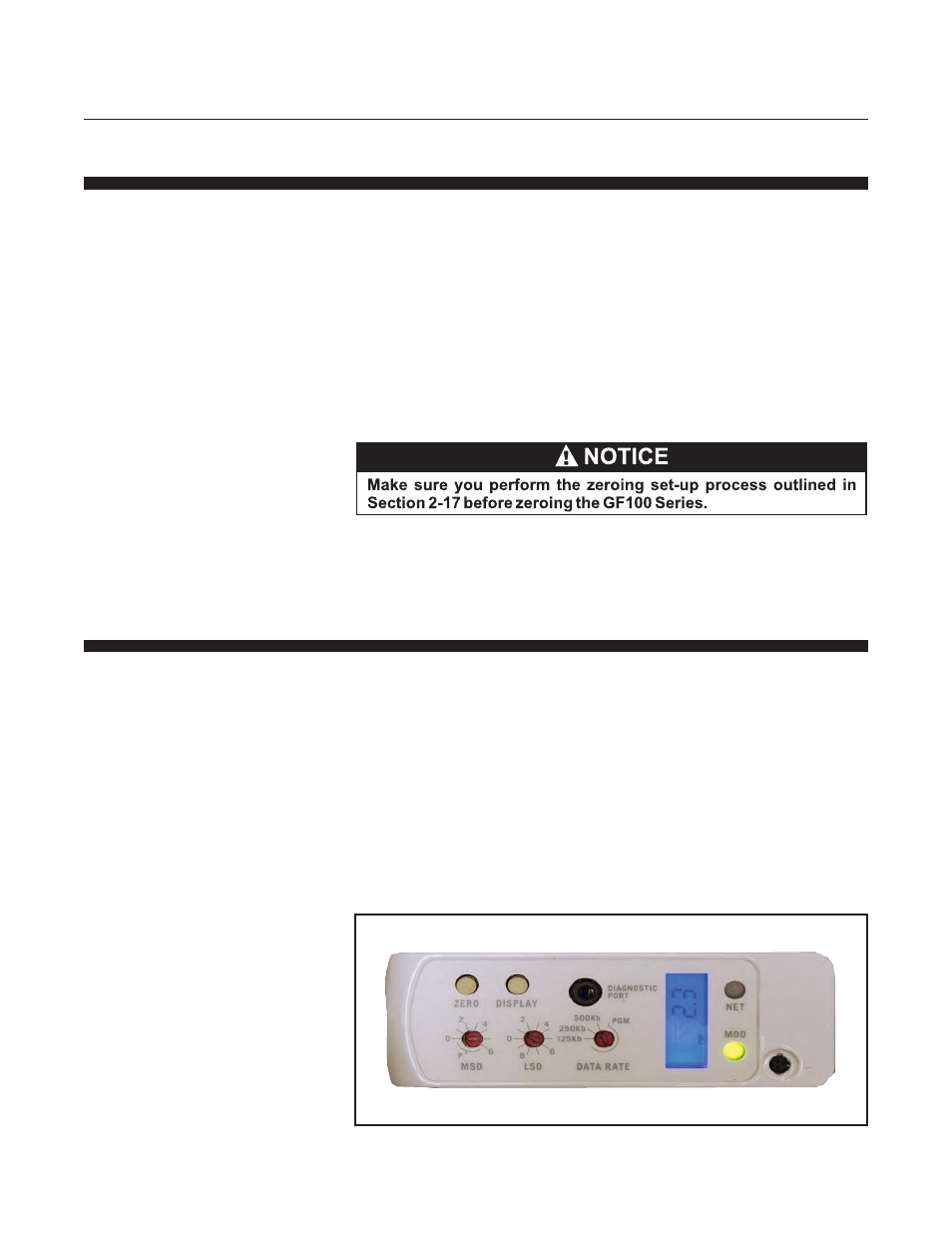

2. Looking at the top of the GF100 Series, press the "Display" button,

starting at the MACID, four times to "PSI" or five times to "kPa" or until

the LCD displays the labels "PSI" or "kPa". The GF100 Series will

display pressure in units of PSIA or kPa. Press and hold down the Zero

button a minimum of 5 seconds or until the display reads 0.000, with the

last two digits flickering at different values. The pressure transducer

zeroing procedure can be done while the display is either in PSIA or

kPA output. Refer to Figure 2-6.

Figure 2-6 Display with PSI Reading