Assembly – Grain Systems Bucket Elevtors, Conveyors, Series II Sweeps PNEG-1579 User Manual

Page 51

Assembly

39

PNEG-720-G2 12" & 16" Series II Sweep

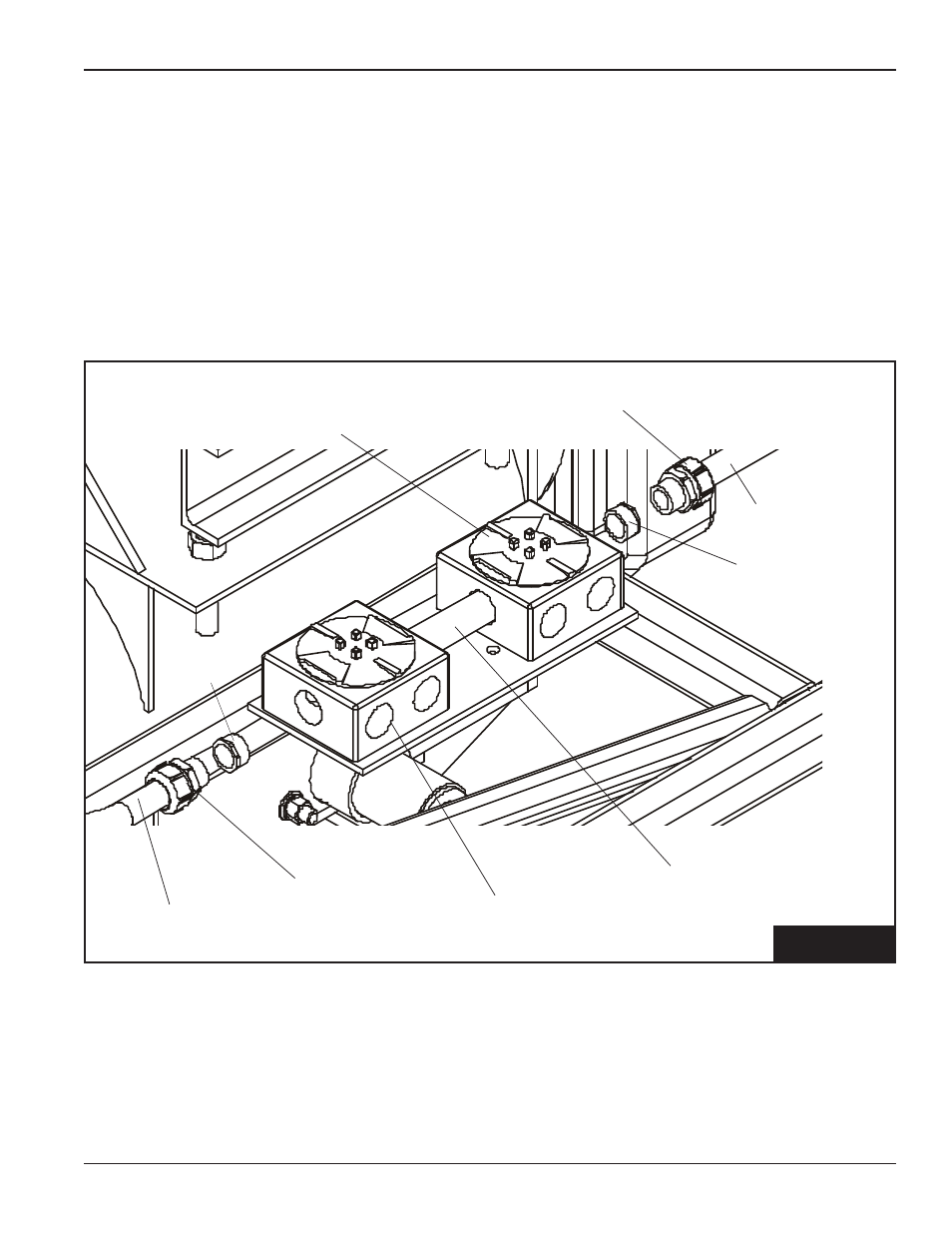

D. Attach the 3/4" x 12" liquid-tight flex conduit to the other end of the rigid conduit using one (1) 3/4"

conduit coupling and one (1) 3/4" liquid-tight flex conduit coupling.

E

Connect the two (2) junction boxes together using the 1" x 4 3/4" conduit nipple.

F. Connect the 3/4" x 12" liquid-tight flex conduit to the left junction box using one (1) 3/4" liquid-tight

flex conduit coupling and one (1) 1" to 3/4" reducer bushing.

G. Attach the 3/4" x 40" liquid-tight flex conduit to the right junction box using one (1) 3/4" liquid-tight

flex conduit coupling and one (1) 1" to 3/4" reducer bushing.

H. Feed each of the six (6) 14 AWG stranded wires through the 3/4" rigid conduit assembly and cut

them off, leaving six inches (6") at both the left junction box and drive motor.

I.

Feed each of the six (6) 10 AWG stranded wires cord through the 3/4" x 40" liquid tight flex conduit

and cut four (4) of them off, leaving six inches (6") at both the right junction box and auger motor.

Cut the 10 AWG blue and yellow wires longer so they can be connected to the 14 AWG blue and

yellow wires in the left junction box.

15. ELECTRICAL ASSEMBLY (cont.)

3/4" x 40"

flex conduit

right junction box

1" to 3/4" reducer

bushing

3/4" flex conduit

coupling

3/4" flex conduit

coupling

3/4" x 12"

flex conduit

1" x 4 3/4" conduit

nipple

left junction box

FIG. 15-G

reducer

bushing