Assembly – Grain Systems Bucket Elevtors, Conveyors, Series II Sweeps PNEG-1579 User Manual

Page 27

Assembly

27

PNEG-720-G2 12" & 16" Series II Sweep

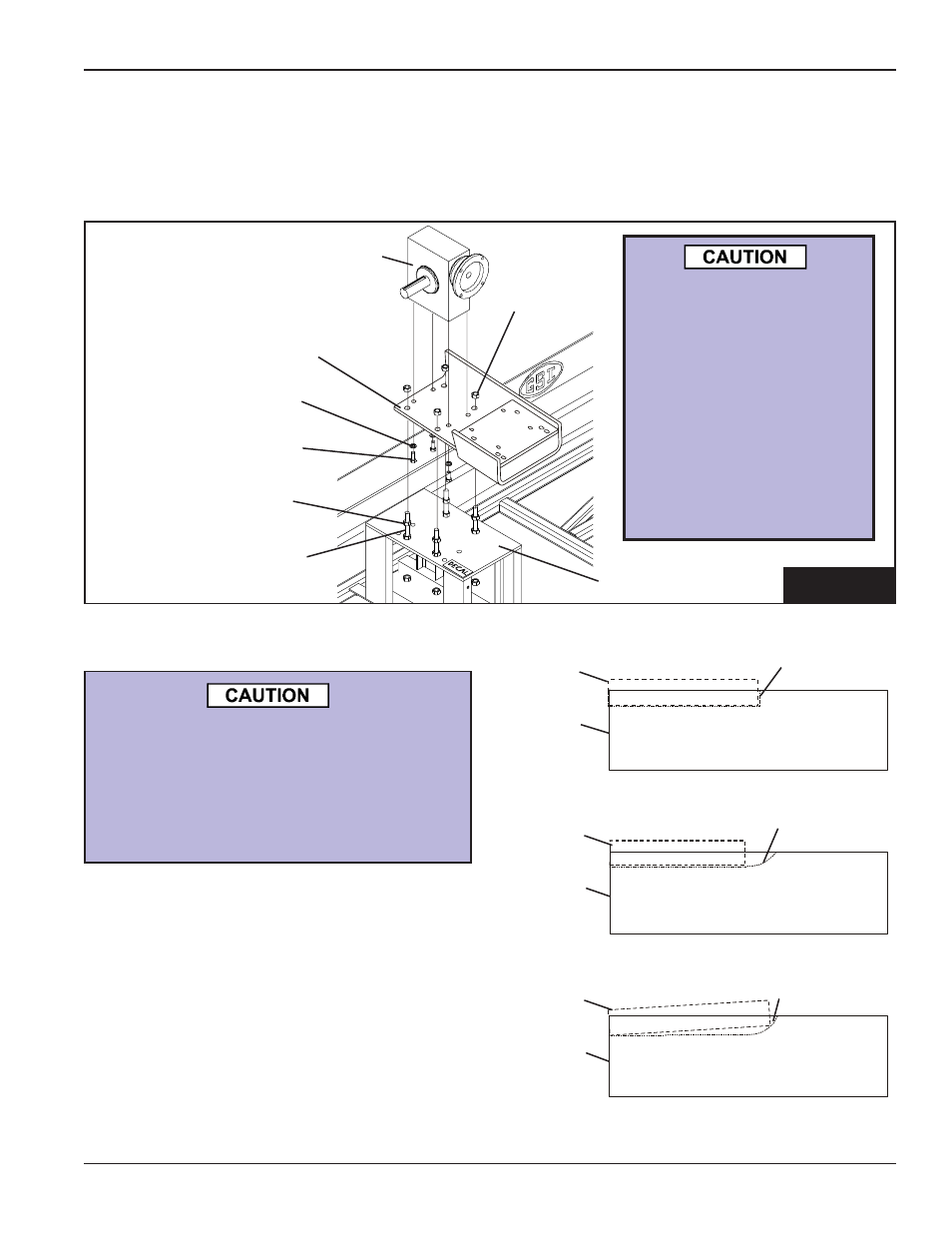

A. Attach the C-Face reducer to the mounting plate using four (4) 1/2"-13 x 1-1/4" hex bolts and

lockwashers.

B. Fasten the mounting plate to the tail section plate using four (4) 5/8"-11 x 6" all-thread rods and

sixteen (16) hex nuts. Adjust the mounting plate as close as possible to the tail section plate.

hex nut

lockwasher

C-Face Reducer

reducer

mounting plate

5/8" x 6" all-thread rod

hex nut

1/2"-13 x 1 1/4" hex bolt

tail section plate

FIG. 7

8-A. KEY ALIGNMENT

7. INSTALL REDUCER MOUNTING PLATE & REDUCER

The gear reducer is NOT

filled with oil from the

factory. For gear re-

ducer specifications

and oil fill recommenda-

tions, refer to the own-

ers manual supplied

with the reducer or the

lubrication information

in the maintenance

section of this manual.

All keys should be parallel to the drive

shaft. If the key is not straight (parallel)

the gearbox quill sleave will crack.

THIS TYPE OF DAMAGE IS NOT

COVERED BY WARRANTY.

1. Place key in keyway on drive shaft.

2. Make sure key is flat (parallel to drive shaft) in

keyway as in Figure 8A-1 and 8A-2. NOT like

Figure 8A-3.

3. Line up keyway on shaft with keyway on reducer

and insert shaft into motor. (See Figure 8A-4 on

page 30.)

Key

Drive

Shaft

FIGURE 8A-1

Key correctly positioned in a straight routed

keyway. (Profiled keyway)

Keyway

Key

Drive

Shaft

FIGURE 8A-2

Key correctly positioned in a scalloped

routed keyway. (Sled runner keyway)

Keyway

Key

Drive

Shaft

FIGURE 8A-3

Key INCORRECTLY positioned in a

scalloped routed keyway. DO NOT install

key in this position.

Keyway