3 selection of the drying temperature – Ohaus MB45 MOISTURE ANALYZER Manual User Manual

Page 51

MB45

49

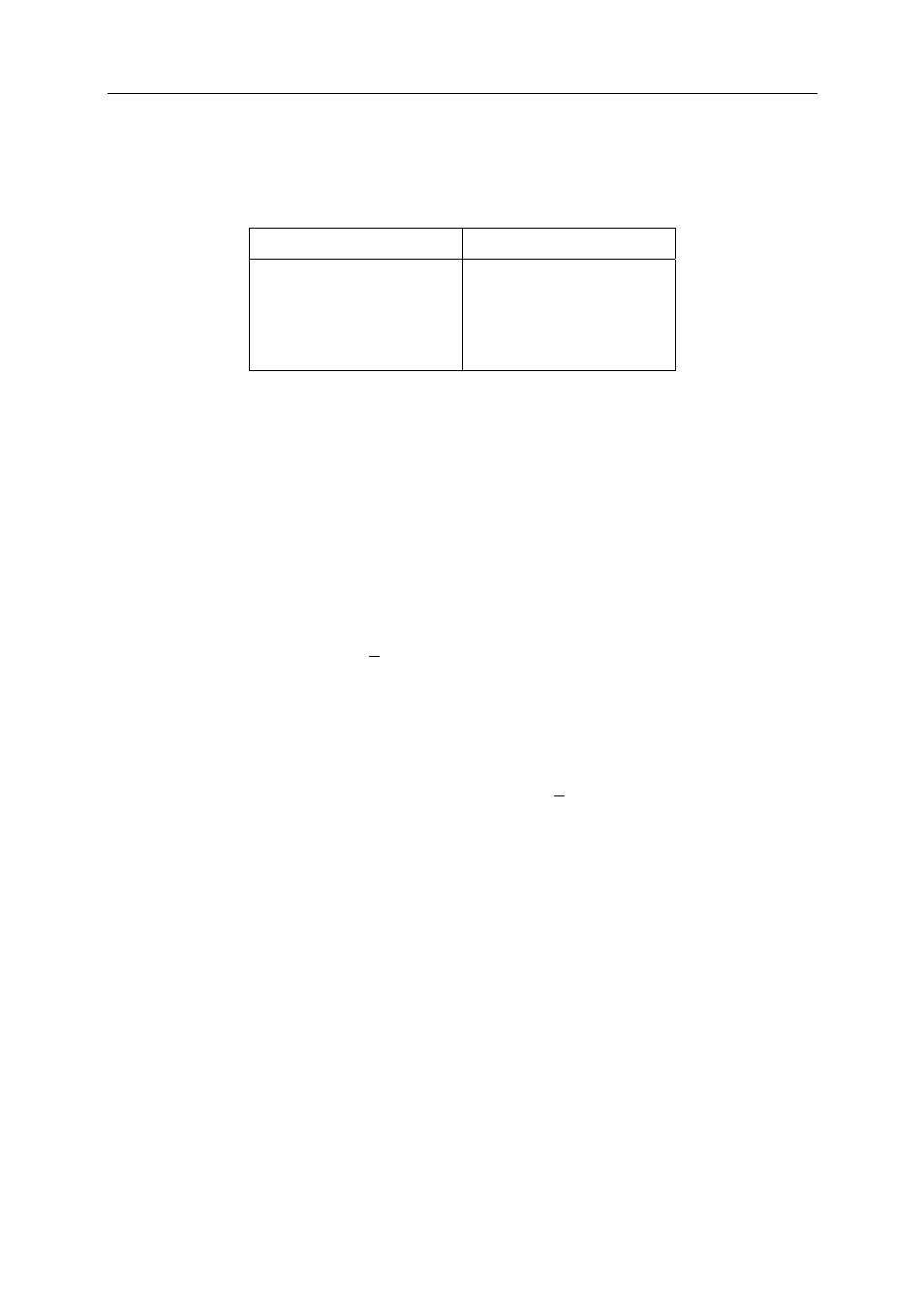

Influence of the sample weight on the repeatability of the results

Sample weight influences the repeatability of the Moisture Analyzer. The repeatability always becomes

worse with decreasing sample weight. The relation between sample weight and repeatability is shown in

the following table:

Sample weight

Repeatability

0.5g

1g

2g

5

10g

±0.6%

±0.3%

±0.15%

±0.06%

±0.03%

The preceding table is based on the assumption that the sample is ideal, homogeneous and its moisture

can always be separated completely and free from decomposition (e.g. moist sand). Deviations always

comprise the uncertainty, which depends on the sample, and the repeatability of the instrument. In

practice, measurement differences appearing within a measurement series can consequently be larger

than the values of the halogen Moisture Analyzer shown in the table.

The two examples below show how the sample weight is determined to keep the drying time to a

minimum and meet the accuracy demands of the instrument.

Example 1

The repeatability should be better than +0.15%. The accuracy table shows that a sample weight of at

least 2g is required to achieve this.

Example 2

Wet weight of sample:

10g

Mean value of the results:

15.5%

Repeatability from the table:

+0.03%

Scatter of the measurement results (ideal sample)

15.47% –15.53%

8.3 Selection of the drying temperature

The drying temperature exerts a controlling influence on the measurement time. It must be selected so

that the sample neither decomposes nor changes its chemical structure. A drying temperature that is too

low can unnecessarily prolong the drying time.

Note also that certain samples can give off different amounts of moisture at different drying temperatures.

This is the case with substances in which the strength of the bonds binding the moisture varies or those

which tend to show signs of decomposition. Minimum deviations from moisture content values of the

reference method can be compensated by changing the drying temperature.