20 connection and mounting data – M&C TechGroup SP2400-H Operator's manual User Manual

Page 42

42

Gas sampling and gas conditioning technology

2-1.1-ME

20

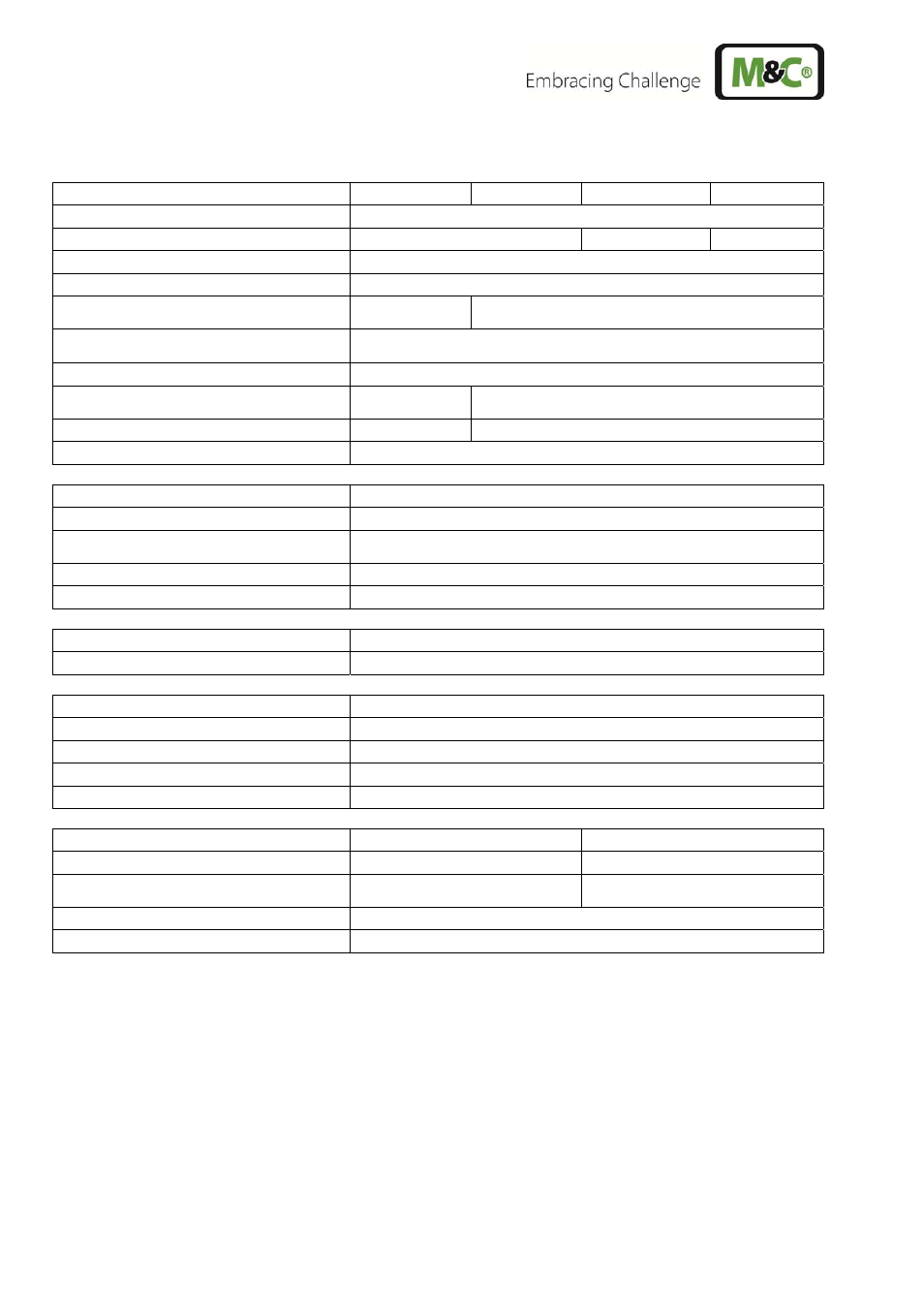

CONNECTION AND MOUNTING DATA

Gas sample probe type

SP2000

SP2000-H

SP2300-H

SP2400-H

Dimensions B x H x T

340 x 260 x 345

Material filter housing

SS316Ti* PTFE-Ko

Titanium

Sealing materials

FPM* /7aT** = PTFE /H320** = Graphite

Material probe flange gasket

Novapress

Low temperature alarm contact

Switching capacity: 250V, 3A~, 0,25A=,

switching point: ∆T 30°C

Connection

gas outlet / second gas outlet

1 x ¼“NPTi* for tube connection

6, 8 or 10mm**, /H320** = 6mm* or

8mm**

Blow back-/test gas connection

¼“NPTi*, /R** and H320** = tube

6mm

Power supply / wattage / fuse protection

230V 50/60Hz, 800W, /115V** = 115V 60Hz, 800W

fuse protection 10A

Electrical connection

Terminals max. 4mm

2

, 2 x M20 x 1,5 cable gland

Mounting flange

DN65 PN6, form B, 1.4571*, >DN or ANSI possible**, /HP**=DN50 PN25

Controller type

70304G

Dimensions B x H x T

150 x 250 x 145

Status signal output

Low temperature alarm: 1 contact NO, potential free. Switching capacity

max. 250VAC 3A

Electrical connection

Terminals max. 4mm

2

, 4 x M20 x 1,5 cable gland

Power supply

115V 50/60Hz 1725VA, 230V 50/60Hz 3450VA

Pneumatic ball valve drive type

MS1 a

nd MS3

Connection control line

G1/4 “ i

Electrical ball valve drive type

EA

Status signal output

Position end switch 250VAC, 11A AC, 0,25A DC** (mains potential)

Electrical connection

Terminals max. 4mm

2

, 2 x M20 x 1,5 cable glands

Power supply

230V 50Hz, 140W (115V 60Hz or 24V DC)

Status signal potential free**

2 x position end switch, potential free, open/closed, 250V, 16A

Solenoid valve units type

2

3

Dimensions B x H x T

270 x 270 x 150

270 x 270 x 190

Pneumatic connections

2 x control air G1/4“i

2 x blow back G3/8“i

2 x control air G1/4“i

3 x blow back G3/8“i

Elektrical connections

Terminals max. 4mm

2

, 3 x M20 x 1,5 cable gland

Power supply

115V 50/60Hz 20W, 230V 50/60Hz 20W, 24V DC 20W

* Standard

** optional