M&C TechGroup SP2400-H Operator's manual User Manual

Page 28

28

Gas sampling and gas conditioning technology

2-1.1-ME

This type of calibration gas feeding is not to be used in case of processes with over pressure. A

built-in ball valve in the probe entrance is recommended here. Basically, a smaller amount of cali-

bration gas is needed in probes with built-in ball valve as the probe is separated from the system on

activating the ball valve and thus there is no danger of mixing with the process gas.

In order to close the probe the control grip has to be turned by hand to the right up to the stop.

N O T E !

In case of vacuum care should be taken that no infiltrated air is drawn in

via the unclosed non-return valve from 300 mbar upwards.

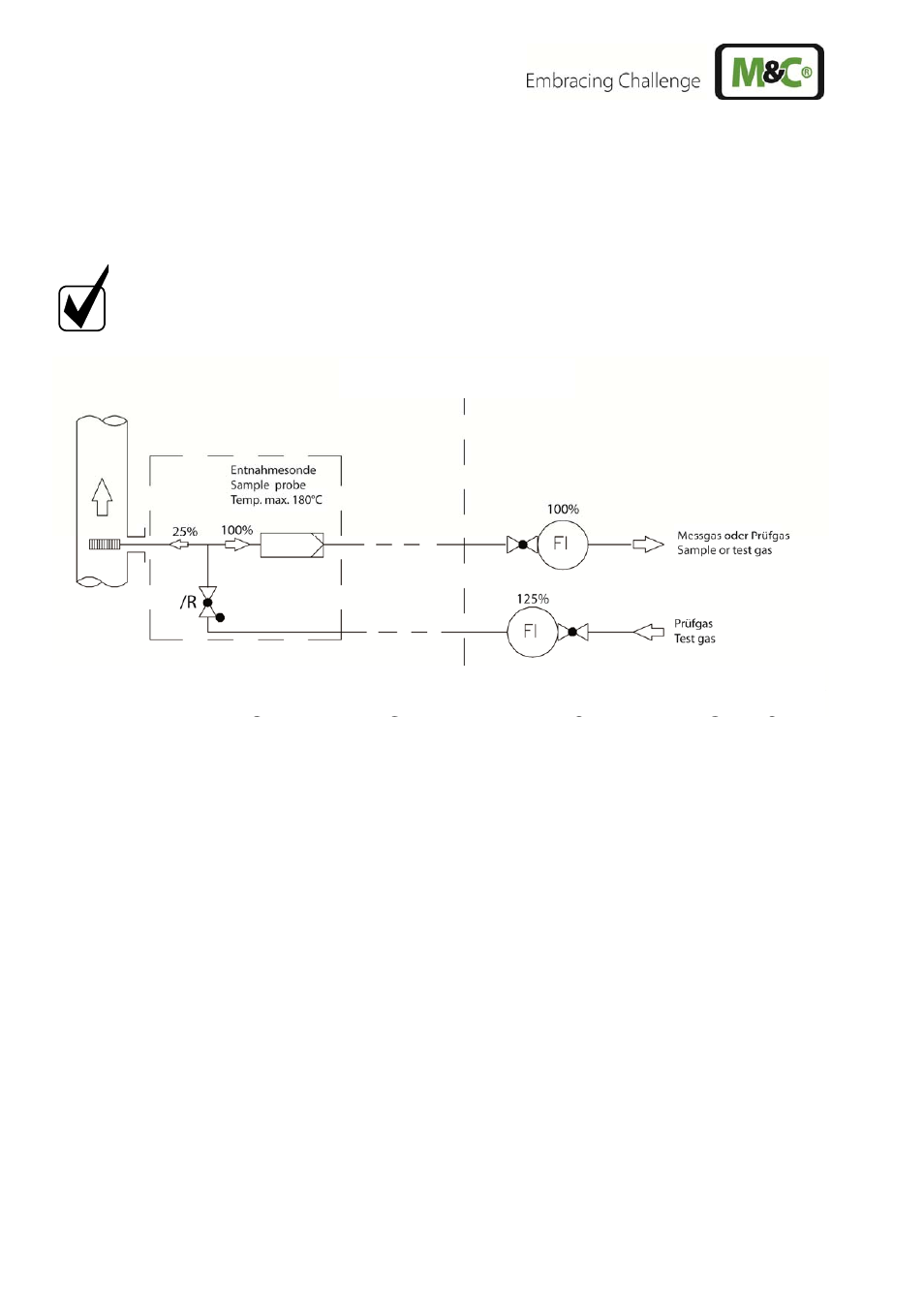

Figure 12

Calibration gas feeding

16.2.2

VIA 3/2 WAY BALL VALVE /3VA

With the 3/2 way ball-valve the two functions "backflush and calibration gas feed" can be carried out

one after the other. Only one function can be automated via the pneumatic drive.

This method of gas feed has the advantage that during backflushing the downstream analysis system

is automatically separated from the probe and during calibration gas feed, the probe is automatically

separated from the process and therefore a smaller amount of calibration gas is needed as no mixing

with the process gas can occur. During function blow back it is possible to feed test gas via an addi-

tional check valve /R at the same time (see also Fig. 13).

For sampling operation turn handle to mid position.

For blow back turn handle from mid to left positon up to stop.

For test gas feeding turn handle from mid to right position up to stop.

For measuring operation turn handle back to mid position.

When feeding calibration gas via check valve /R at the probe, mixing with sample gas must be avoided. The

calibration gas flow should be at least 25% higher than the flow of sample gas.