3 reference quantities – Siemens MICROMASTER 420 User Manual

Page 50

3 Functions

Issue 07/04

MICROMASTER 420 Operating Instructions

50

6SE6400-5AA00-0BP0

3.1.3 Reference

quantities

Parameter range:

P2000 - P2002

When being output or read-in by the drive inverter, physical quantities are

normalized or de-normalized. This conversion is made directly by the particular

interface using the reference quantities. The normalization / de-normalization is

carried-out for the following interfaces:

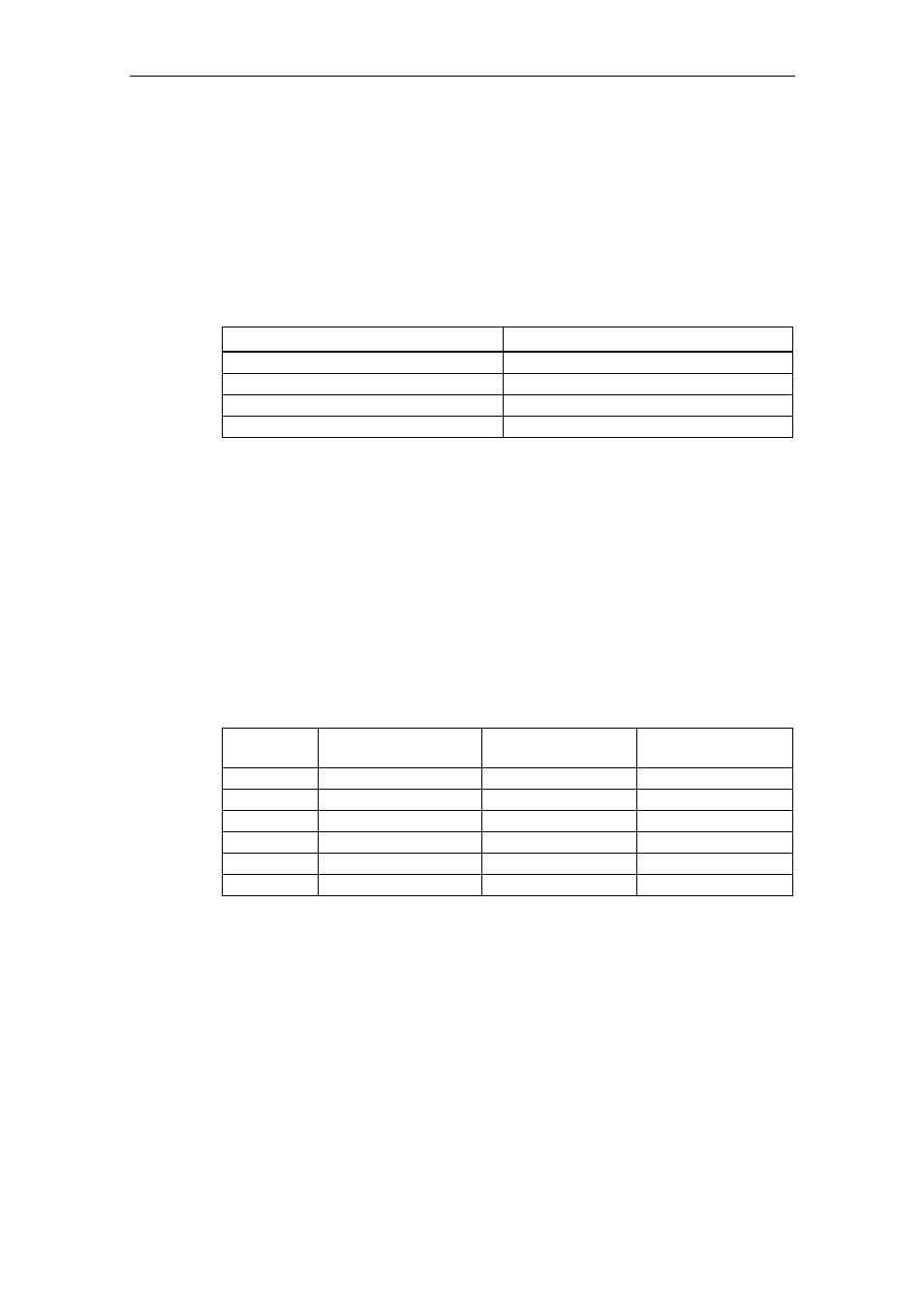

Table 3-5

Normalized interfaces

Interface 100

%

Analog input (voltage input)

10 V

Analog output (current output)

20 mA

USS 4000

h

CB 4000

h

Further, a normalization is carried-out for a BICO connection if the connector

output (CO) represents a physical quantity and the connector input (CI) a

normalized (percentage) quantity (e.g. PID controller). A de-normalization is

carried-out if the inverse applies.

Reference quantities (normalization quantities) are intended to allow setpoints and

actual signals to be represented in a uniform, standard way (normalization / de-

normalization of physical quantities such as setpoint and actual frequency). This

also applies to permanently set parameters that are assigned the "percentage"

units. A value of 100 % corresponds in this case to a process data value PZD of

4000 h (USS or CB) or a current value of 20 mA (analog output) or a voltage value

of 10 V (analog input). The following reference parameters and permanently saved

reference values are available:

Table 3-6

Normalization functions

Parameter

Designation

Value (100 % / 4000

h)

Units

P2000 Reference

frequency

P2000

Hz

P2001 Reference

voltage P2001

V

P2002 Reference

current P2002

A

- Reference

speed

P2000

* 60 / r0313

RPM

-

Reference temperature

100 °C

°C

-

Reference energy

100 kWh

kWh