2 compound braking – Siemens MICROMASTER 420 User Manual

Page 125

Issue 07/04

3 Functions

MICROMASTER 420 Operating Instructions

6SE6400-5AA00-0BP0

125

3.14.2 Compound

braking

Parameter range:

P1236

Warnings -

Faults -

Function chart number:

-

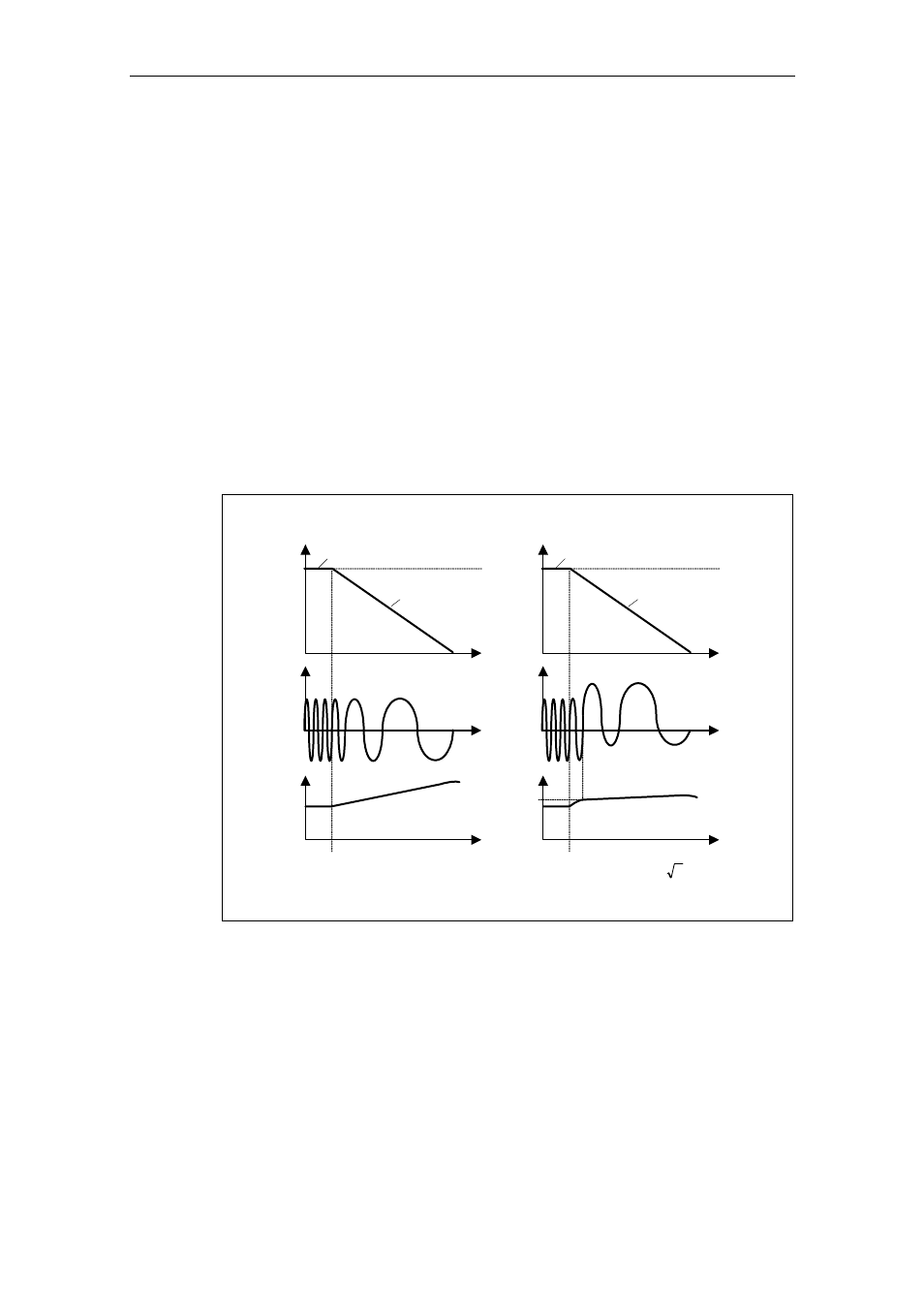

For compound braking (this is enabled using P1236) DC braking is superimposed

with regenerative braking (where the drive regenerates into the line supply as it

brakes along a ramp). If the DC link voltage exceeds the compound switch-in

threshold V

DC-Comp

(refer to Fig. 3-53), then a DC current is impressed as a function

of P1236. In this case, braking is possible with a controlled motor frequency and

minimum regenerative feedback. Effective braking is obtained without having to

use additional components by optimizing the ramp-down time (P1121 for OFF1 or

when braking from f

1

to f

2

, P1135 for OFF3) and using compound braking P1236.

Compound braking is suitable for:

Horizontal motion (e.g. traversing drives, conveyor belts)

Vertical motion (e.g. hoisting gear)

f

i

t

t

f_act

f_set

P1236 = 0

Without Compound braking

u

t

f

i

t

t

f_act

f_set

P1236 >0

With Compound braking

t

DC-link

u

DC-link

U

DC-Comp

P0210

2

13

.

1

U

:

0

=

P1254

Comp

-

DC

⋅

⋅

=

1242

r

0.98

U

:

0

P1254

Comp

-

DC

⋅

=

≠

Fig. 3-53

Compound braking

The compound braking switch-in threshold V

DC-Comp

is calculated as a function of

parameter P1254 (Auto detect V

DC

switch-on levels) either directly using the line

supply voltage P0210 or indirectly using the DC link voltage and r1242 (refer to the

formula in Fig. 3-53).