11 pid controller (technological controller) – Siemens MICROMASTER 420 User Manual

Page 106

3 Functions

Issue 07/04

MICROMASTER 420 Operating Instructions

106

6SE6400-5AA00-0BP0

3.11

PID controller (technological controller)

Parameter range:

P2200

P2201 – r2294

Warnings -

Faults -

Function chart number:

FP3300, FP3310, FP3400, FP5100

Features:

- cycle time:

8 ms

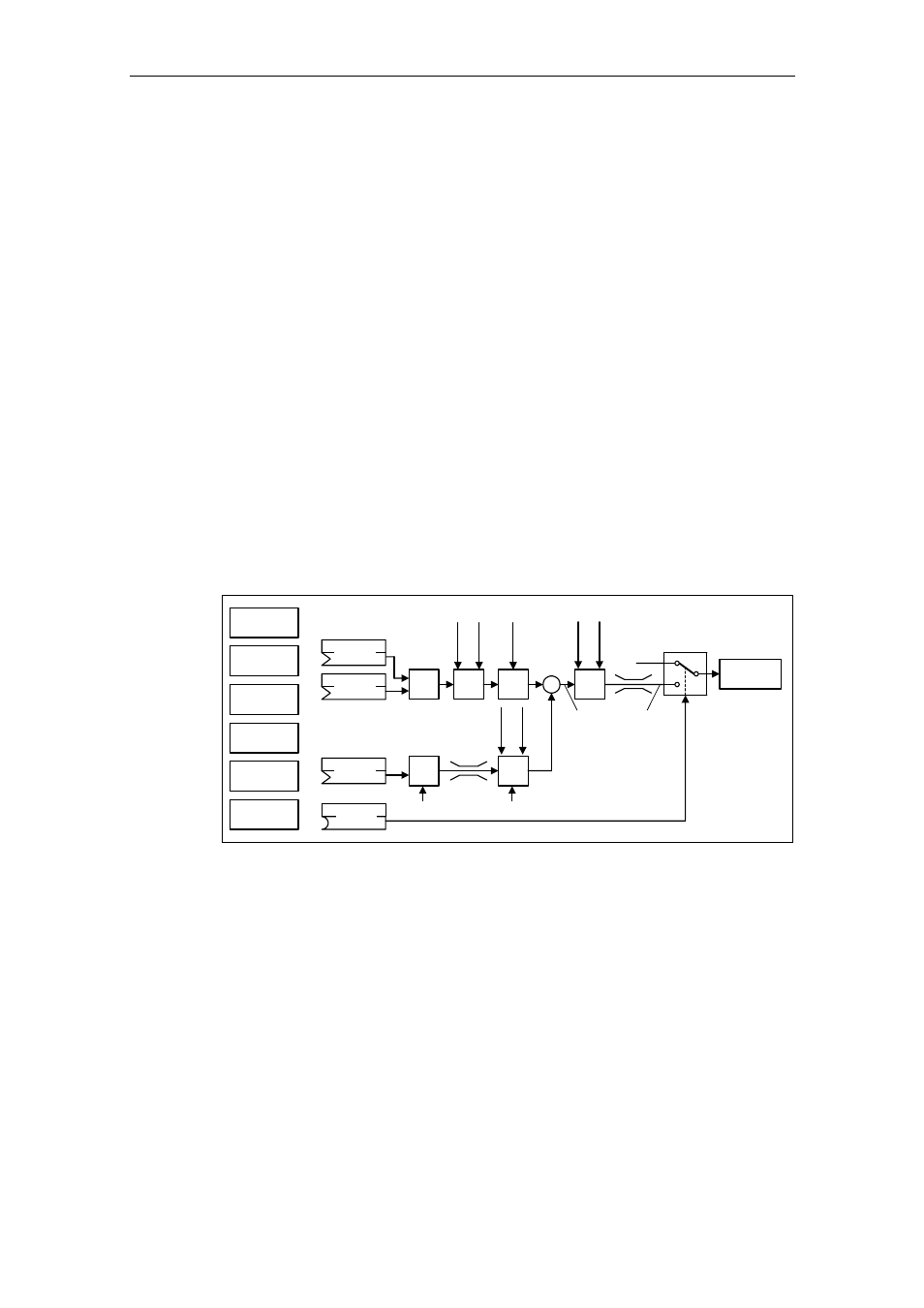

MICROMASTER has an integrated technological controller (PID controller, enabled

via P2200). This can be used to process basic higher-level control functions. These

typically include:

Pressure control for extruders

Water level control for pump drives

Temperature control for fan drives

And similar control tasks

The technological setpoints and actual values can be entered via the PID

motorized potentiometer (PID-MOP), PID fixed setpoint (PID-FF), analog input

(ADC) or via serial interfaces (USS on BOP link, USS on COM link, CB on COM

link) (refer to the example). The appropriate parameterization of the BICO

parameter defines which setpoints or actual values are to be used (refer to Fig.

3-36).

PID

MOP

ADC

PID

SUM

PID

PID

FF

USS

BOP link

USS

COM link

CB

COM link

P2254

P2253

PID

RFG

PID

PT1

− ∆

PID

P2200

P2264

PID

PT1

PID

SCL

Output

PID

0

1

Motor

control

P225

7

P225

8

P226

1

P2271

P2

269

P2

270

P2265

P22

80

P22

85

Fig. 3-36

Structure of the technological controller (PID controller)