Siemens MICROMASTER 420 User Manual

Page 111

Issue 07/04

3 Functions

MICROMASTER 420 Operating Instructions

6SE6400-5AA00-0BP0

111

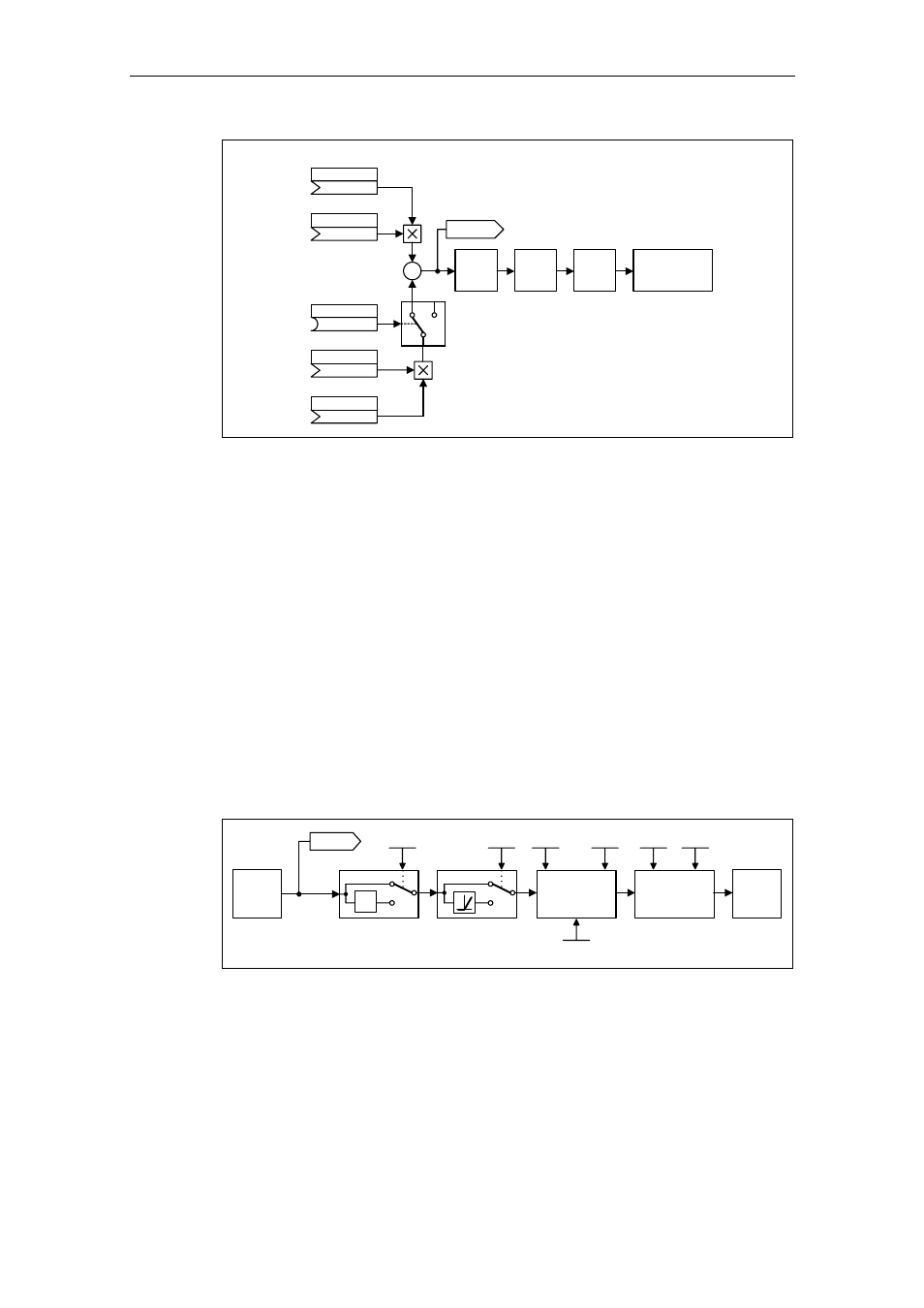

AFM

Limit

RFG

r1078

0

1

CI: Add. setp.scal

(1:0)

P1076.C

CI: Add. setpoint

(0:0)

P1075.C

(0:0)

BI: Disab.add.setp

P1074.C

CI: Main setp scal

(1:0)

P1071.C

CI: Main setpoint

(755:0)

P1070.C

+

+

Motor

control

Fig. 3-40

Summation

MICROMASTER has the following possibilities to select the setpoint source:

1. P1000 – selecting the frequency setpoint source

2. P0719 – selecting the command / setpoint source

3. BICO

parameterization

- P1070 CI: Main setpoint

- P1075 CI: Additional setpoint

Further, the main setpoint as well as the supplementary (additional) setpoint can be

scaled independently of one another. In this case, for example, a user can simply

implement an override function using the appropriate parameterization.

A scan sequence is generally associated with a forwards and a backwards motion.

When selecting the reversing functionality, after reaching the end position, a

direction of rotation reversal can be initiated in the setpoint channel (refer to Fig.

3-41).

On the other hand, if it is to be prevented that a direction of rotation reversal or a

negative frequency setpoint is to be entered via the setpoint channel, then this can

be inhibited using BICO parameter P1110.

SUM

-1

0

1

0

1

P1113

r1078

P1110 P1091

P1094

P1101

...

Skip

Limit

P1080 P1082

RFG

Fig. 3-41

Modifying the frequency setpoint

Driven machines can have one or several resonance points in the range from 0 Hz

up to the reference frequency. These resonance points result in oscillations which,

under worst case conditions, can damage the driven load. Using suppression

frequencies, MICROMASTER allows these resonant frequencies to be passed

through as quickly as possible. This means that the suppression frequencies

increase the availability of the driven load over the long term.