17 closed-loop vdc control, 1 vdc_max controller – Siemens MICROMASTER 420 User Manual

Page 131

Issue 07/04

3 Functions

MICROMASTER 420 Operating Instructions

6SE6400-5AA00-0BP0

131

3.17

Closed-loop Vdc control

3.17.1 Vdc_max

controller

Parameter range:

P1240, r0056 bit 14

r1242,

P1243

P1250 – P1254

Warnings A0502,

A0910

Faults F0002

Function chart number:

FP4600

DC link undervoltage

Cause:

Line supply voltage failure or dip (blackout or brownout)

Remedy:

A regenerative torque is entered for the operational drive which compensates

the existing losses and therefore stabilizes the voltage in the DC link. This

technique is carried-out using the Vdc_min controller (refer to Section 3.18) and

is known as kinetic buffering.

A brief regenerative load can be handled using this function (enabled using P1240)

without the drive inverter being shut down (tripped) with fault message F0002 ("DC

link overvoltage"). In this case, the frequency is controlled so that the motor doesn't

go too far into regenerative operation.

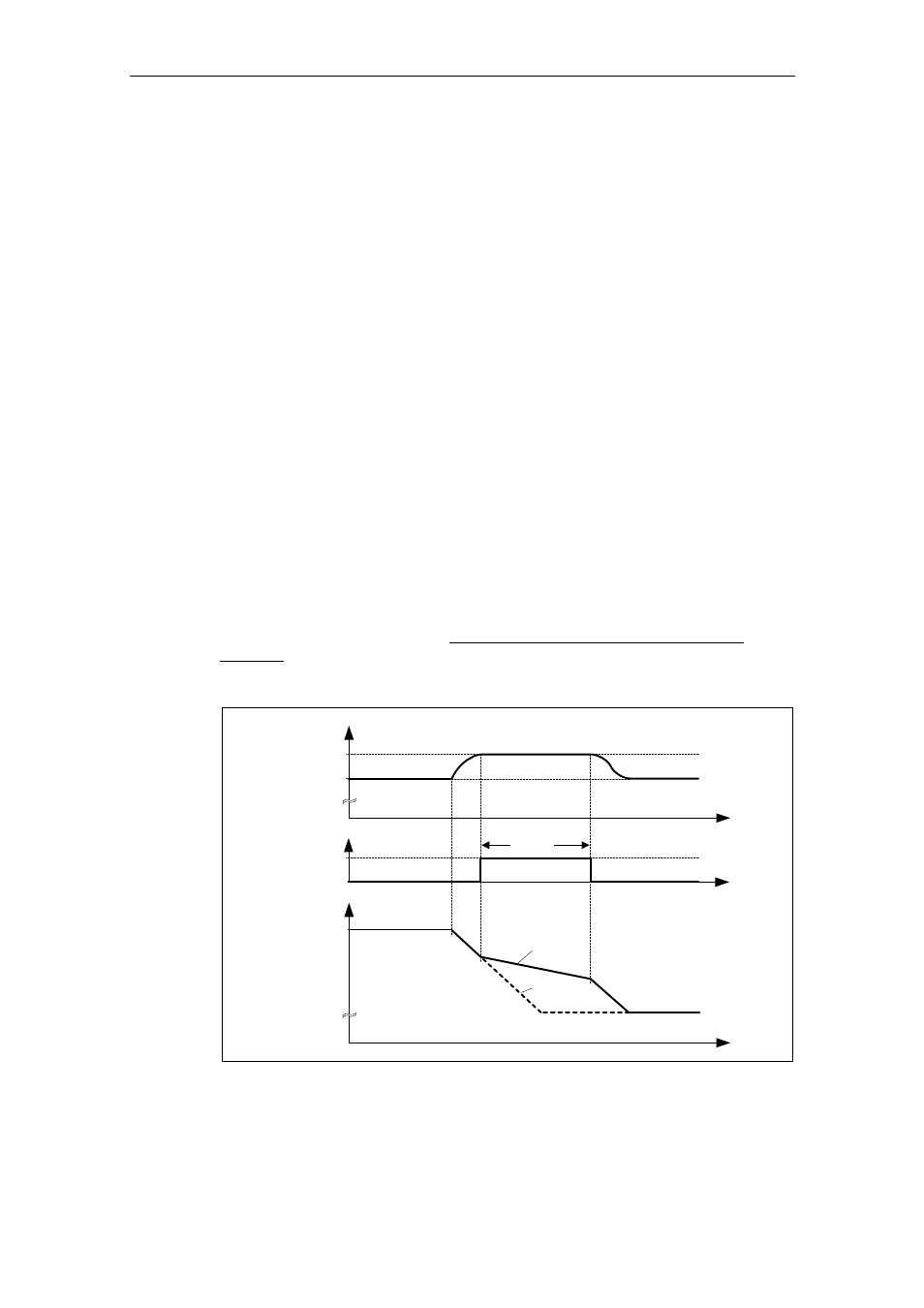

If the drive inverter regenerates too much when braking the machine due to a fast

ramp-down time P1121, then the braking ramp / ramp time are automatically

extended and the drive inverter is operated at the DC link voltage limit r1242 (refer

to Fig. 3-55). If the DC link threshold r1242 is again fallen below, then the Vdc_max

controller withdraws the extension of the braking ramp.

t

t

f

1

-controller active

V

DC_max

t

V

DC

r1242

0

r0056 Bit 14

f

f

act

set

A0911

Fig. 3-55

Vdc_max controller