Siemens MICROMASTER 420 User Manual

Page 141

Issue 07/04

3 Functions

MICROMASTER 420 Operating Instructions

6SE6400-5AA00-0BP0

141

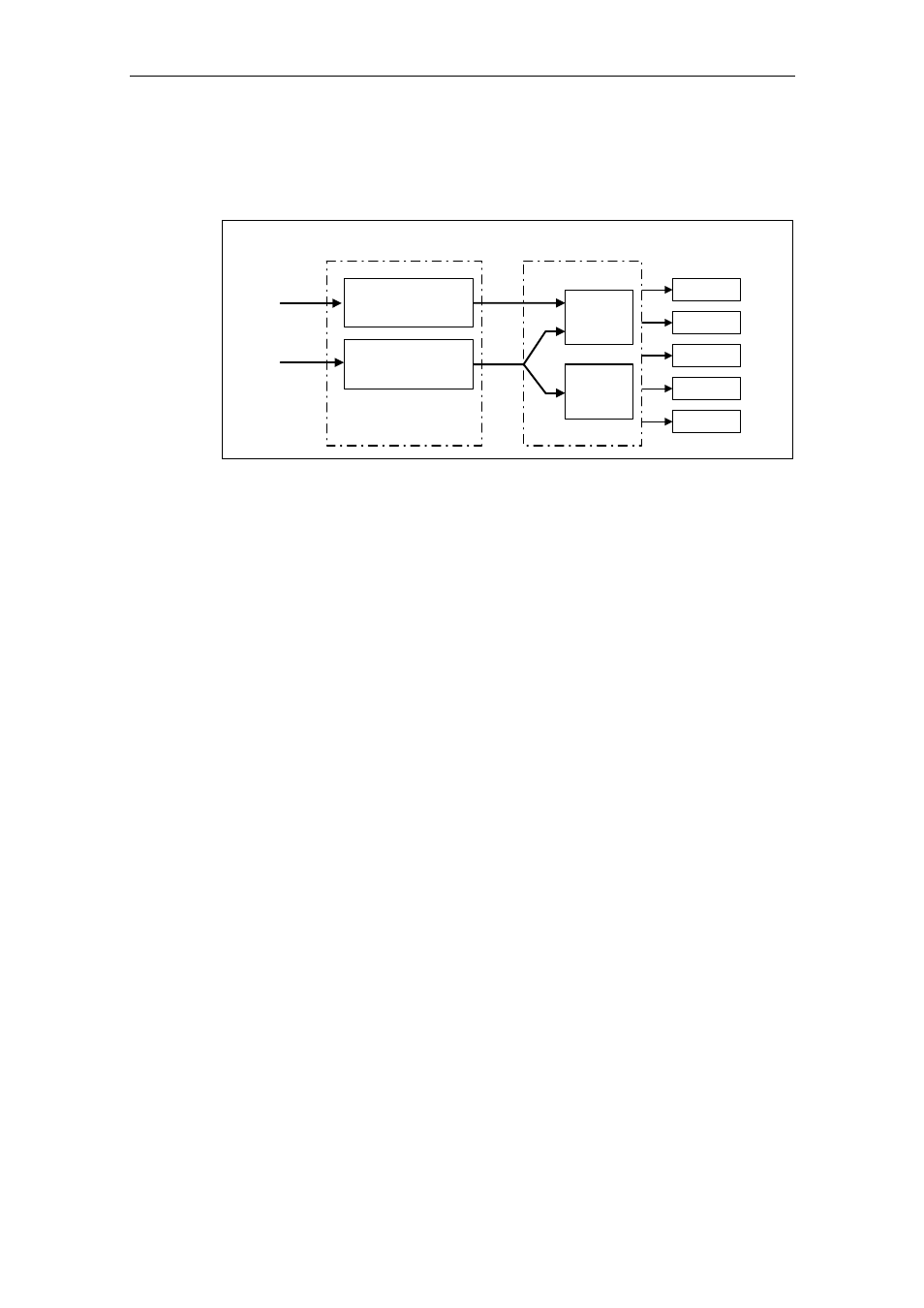

When an overload occurs regarding one of these monitoring functions, initially, a

warning is output. The warning threshold P0294 (i

2

t monitoring) and P0292

(heatsink temperature monitoring) can be parameterized relative to the shutdown

values.

f_pulse

control

i_max

control

A0504

A0505

A0506

F0004

F0005

Inverter overload reaction

P0290

r0036

r0037

Heat sink

temperature

P0292

i

2

t

P0294

Inverter monitoring

Fig. 3-60

Overload response of the drive inverter (P0290)

Example

The warning threshold P0292 for the temperature monitoring (heatsink

temperature) is set to 15 °C in the factory. This means that warning A0504 is

output 15 °C below the shutdown threshold.

At the same time that the warning is output, the parameterized responses are

initiated via P0290. Possible responses include:

Reducing the pulse frequency (P0290 = 2, 3)

This is an extremely effective method to reduce losses in the power module, as

the switching losses represent a very high proportion of the overall losses. In

many applications, a temporary reduction of the pulse frequency can be

tolerated in favor of maintaining the process.

Disadvantage

The current ripple is increased when the pulse frequency is reduced. This can

result in an increase of the torque ripple at the motor shaft (for low moments of

inertia) and an increase in the noise level.

Reducing the output frequency (P0290 = 0,2)

This is advantageous if it is not desirable to reduce the pulse frequency or if the

pulse frequency is already set to the lowest level. Further, the load should have

a characteristic similar to that of a fan, i.e. a square-law torque characteristic for

decreasing speed. When the output frequency is reduced, this significantly

reduces the drive inverter output current and in turn reduces the losses in the

power module.