Point deviates / positioning accuracy is poor, Home position slips, Abnormal motor noise or vibration – Panasonic MINAS A4P Series User Manual

Page 173: When in trouble

173

[When in Trouble]

When in

T

roub

le

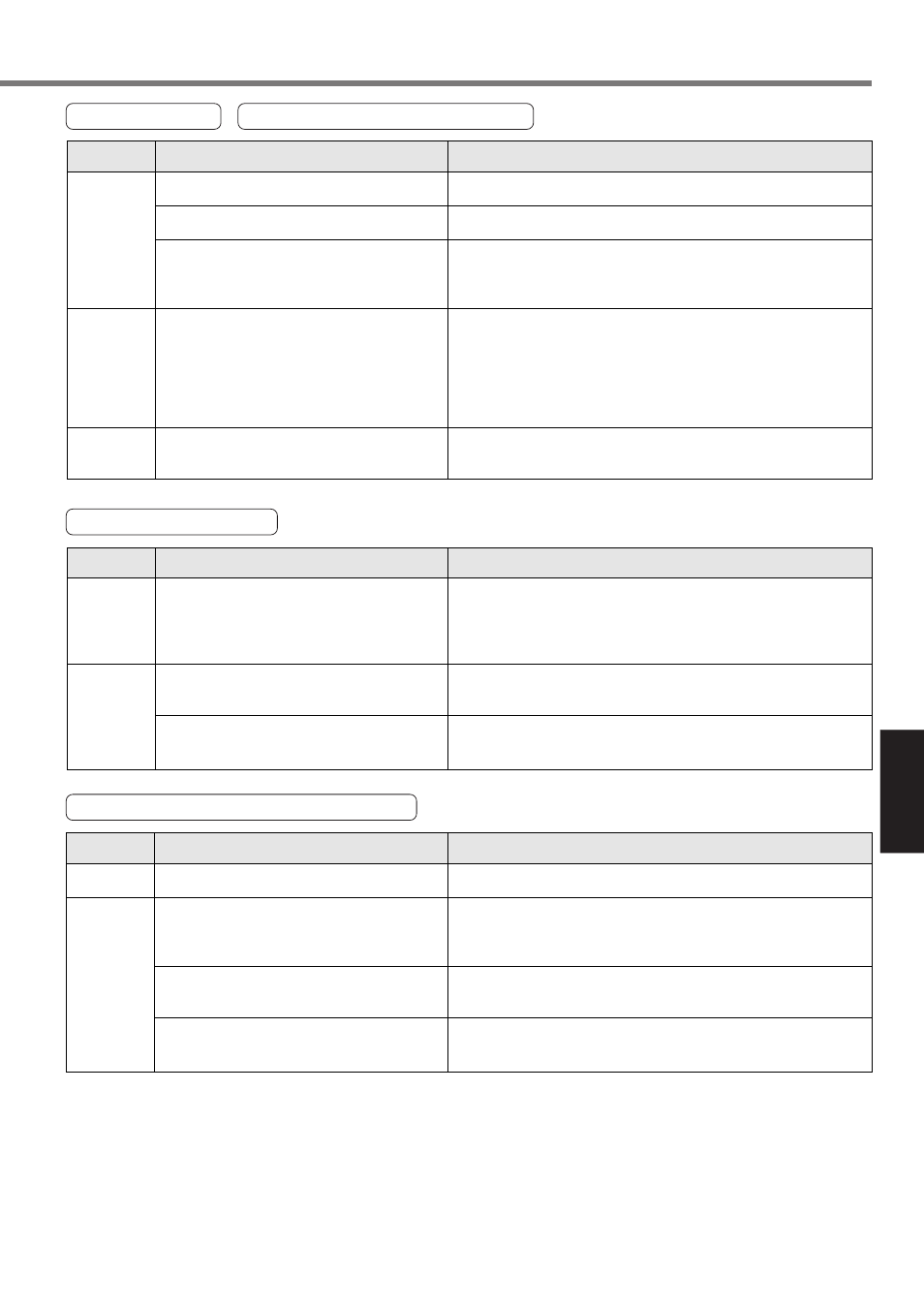

Point Deviates Positioning Accuracy is Poor

Home Position Slips

The setting of the parameter for positioning

operation is wrong.

The setting of positioning completion range is

large.

Position loop gain is small.

Each input signal of CN X5 is chattering.

1)Servo-ON signal

2)CW/CCW over-travel inhibit input

3)Multi function input 1/2

(when a stop command is set)

4)Strobe signal input

5)Point specifying input

Load inertia is large.

Adjust the target position parameter at each point.

Check the setting of an operation mode (relative travel/absolute travel).

Decrease the set value of the positioning completion range (SV.Pr60)

to the extent that chattering does not occur.

Check the position deviation in the monitor mode of the console or

“PANATERM

®

”.

Increase the set value of SV.Pr10 to the extent that oscillation does not

occur and check it.

Check the wiring and connection between each signal of the connector

CN X5 and COM–.

Check the overshoot when stopping with a graphic function of

“PANATERM

®

”. If this problem is not resolved by gain adjustment,

increase the motor and driver capacity.

Parameter

Wiring

Installation

Classification

Causes

Countermeasures

The homing speed is slow, if any of the homing

types below is used.

16.Pr36 =

1:Home sensor (based on the front end)

4: Limit sensor

Chattering of home sensor (Z-LS) input.

Noise is on the encoder line.

Review the set value of the homing speed (16.Pr30/31).

Check home sensor input signal of the controller with oscilloscope.

Review the wiring near to proximity dog and make a noise measure or

reduce noise.

Reduce noise (installation of noise filter or ferrite core), shield

treatment of I/F cables, use of a twisted pair or separation of power

and signal lines.

Parameter

Wiring

Classification

Causes

Countermeasures

Abnormal Motor Noise or Vibration

Gain setup is large.

Resonance of the machine and

the motor.

Motor bearing

Electro-magnetic sound, gear noise, rubbing

noise at brake engagement, hub noise or rub-

bing noise of encoder

Lower the gain by setting up lower values to SV.Pr11 and 19, of

velocity loop gain and SV.Pr10 and 18 of position loop gain.

Re-adjust SV.Pr14 and 1C (Torque filter). Check if the machine

resonance exists or not with frequency characteristics analyzing

function of the PANATERM

®

. Set up the notch frequency to SV.Pr1D

or SV.Pr28 if resonance exists.

Check the noise and vibration near the bearing of the motor while

running the motor with no load. Replace the motor to check. Request

for repair.

Check the noise of the motor while running the motor with no load.

Replace the motor to check. Request for repair.

Adjustment

Installation

Classification

Causes

Countermeasures