Appendix f factory tests – Kipp&Zonen Brewer MkIII User Manual

Page 98

MKIII OPERATOR’S MANUAL

95

APPENDIX F

FACTORY TESTS

SETUP AND CALIBRATION TESTS

The tests and calibration techniques described here are essentially those performed by the factory

before the Brewer Spectrophotometer is shipped. [Refer to the Final Test Record for the set of test

results, graphs, and derived constants for a specific instrument.] Some of these tests (HV, SH)

would only be performed by the user after repair or replacement of one or more of the instrument's

optical or mechanical components. In contrast, the HG (mercury-line calibration) and SL (standard

lamp) tests should be performed at least once per day. The remaining tests should be carried out

at approximately monthly intervals to verify correct instrument performance.

The order in which these tests are described is significant. Tests which follow later in the sequence

assume that the earlier tests and calibrations have been successful. A complete instrument

recalibration (a task not to be undertaken lightly) would therefore follow the ordering implied in this

section.

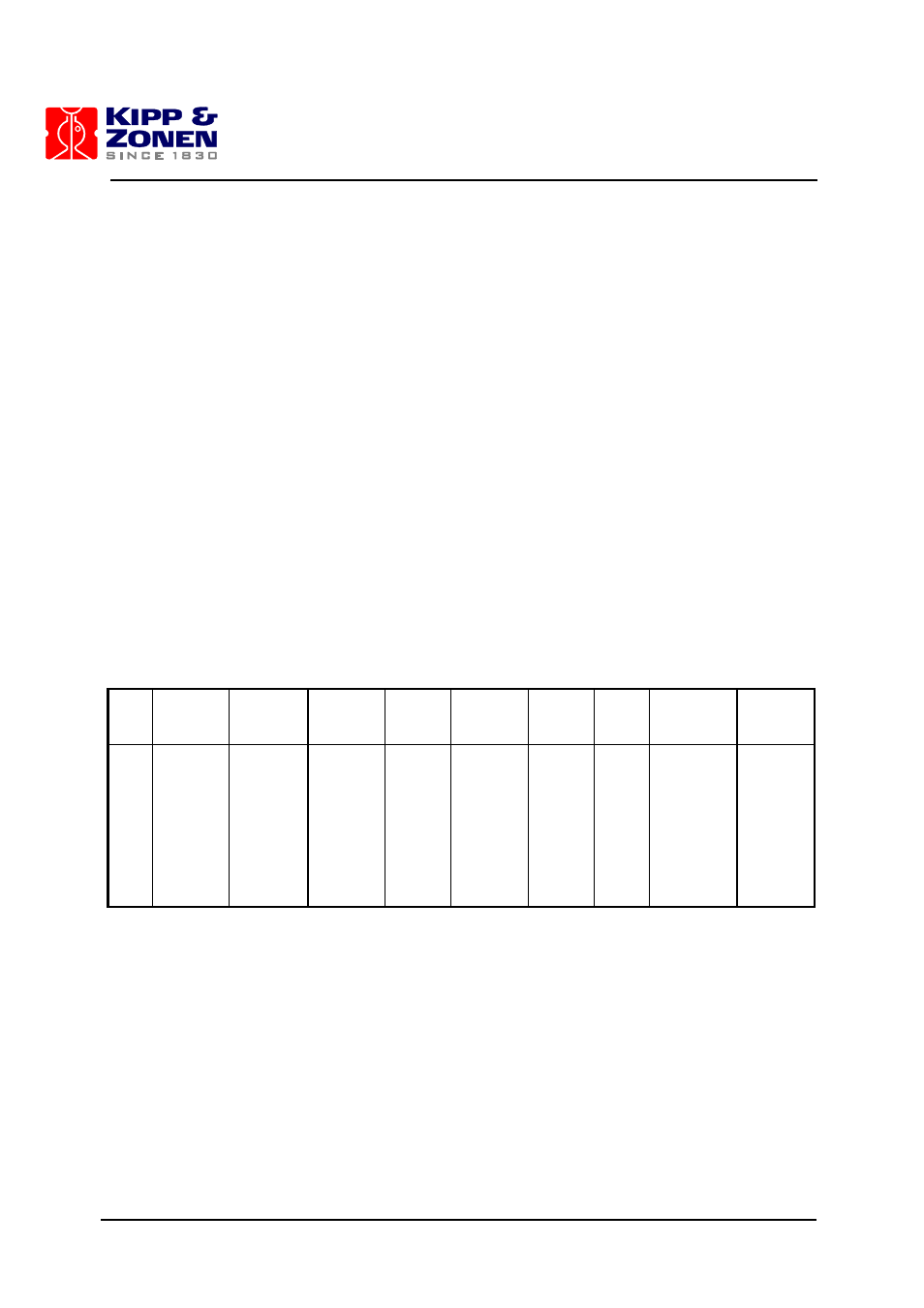

Table F-1 summarizes the settings of the Brewer’s controllable elements for each of the setup

tests. The software will automatically set the elements to where they should be for a specific test.

All of the following tests assume that the spectrometer is in focus and properly aligned in

accordance with the Optical Frame Alignment document.

Table F.1: Settings for Brewer Tests

Test Wave-

Length

Slitmask

Motor

Position

Std Lamp Hg

Lamp

Filter

Wheel 1

Filter

Wheel 2

Iris

Prism

Azimuth

Tracker

DT

Ref

3,5,7

On

Off

1

0,1

Open 180°

N/A

HG Estab Ref 0

Off

On

1

0

Open 180°

N/A

HV Ref

1,2

On

Off

1

0

Open 180°

N/A

RS Ref

0-7

On

Off

1

0

Open 180°

N/A

SC Ref

0-6

Off

Off

1

0,1,2

Close Point at sun Point at

sun

SH Ref

0-2

On

Off

1

0

Open 180°

N/A

SL

Ref

1-6

On

Off

1

0

Open 180°

N/A

SR N/A

N/A

Off

Off

N/A

N/A

N/A

N/A

0°-360°

SH SHUTTER-MOTOR (SLITMASK MOTOR) TIMING TEST

The SH test determines the optimum value for the timing constant used in the control of the

slitmask motor.

Measurements of the Dark Count, and light intensity of the tungsten-halogen (standard) lamp are

taken through the HG and Wavelength 1 slits for a range of motor-delay constants. Observations

are typically made over a range of 20 different values for the delay constant.

APPENDIX F FACTORY TESTS