Kipp&Zonen Brewer MkIII User Manual

Page 104

MKIII OPERATOR’S MANUAL

101

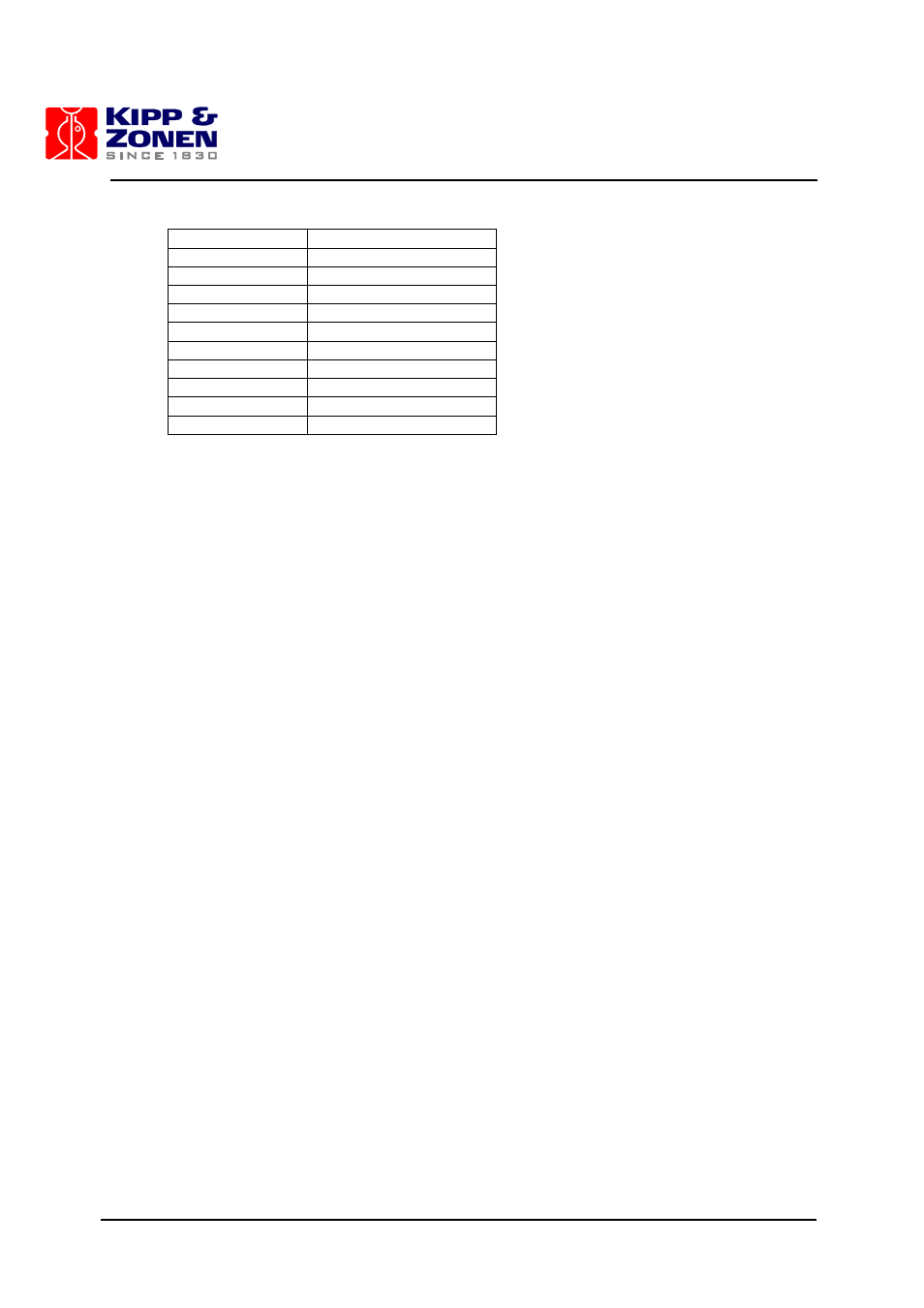

FILTER #1/1 AND FILTER #2/1

GMT

DEADTIME

191424

4.48950597E-08

191449

4.58755779E-08

191513

4.49521729E-08

191538

4.67340357E-08

191603

4.49957964E-08

191627

4.81735377E-08

191652

4.55349271E-08

191716

4.51368558E-08

191741

4.53192958E-08

191805

4.58533414E-08

45.747 ± 1

Following each block of measurements the deadtime mean and deadtime standard deviation (in

nanoseconds) are calculated and printed. The high- and low-intensity deadtime means should

agree (within an acceptance tolerance of two standard deviations), and should lie in the range 35 to

50 nanoseconds. Failure to meet this criterion indicates possible difficulties with either the slitmask

motor operation, the high-voltage circuitry, or photon counting circuitry.

This newly determined deadtime constant should not be entered into the instrument Constants File

unless it is significantly different (by more than about 5 ns) from the old value (if you are confident

that the instrument is currently running properly). You should contact the factory before altering the

stored constant since a complete recalibration may be required.

HG: MERCURY-LINE WAVELENGTH CALIBRATION

The HG test precisely locates the mercury line-spectrum, then repositions the micrometer so that

the diffraction grating disperses the five operating wavelengths onto the appropriate exit slits. The

test uses the mercury discharge lamp and the Hg calibration slit (slitmask position 0).

The software establishes the position of the mercury line-spectrum by scanning the micrometer

forwards from step position 50 to step 280 in 10-step increments, then reversing direction and

scanning from step 280 back to step 50 (note: 1 micrometer step 0.007 nm). At each position the

light intensity dispersed through the calibration slit is recorded, building a 24-point profile of the

mercury spectrum. This measured spectrum is compared with an internally-stored reference

spectrum to determine that step position which

maximizes the correlation between the measured

and stored spectra. If this interpolated step number falls within the acceptance limits

[147.00..149.99] the mercury spectrum is deemed to have been located, and the micrometer is

moved to its operational setting (step number 286 ± 3, or 13 ± 3 micrometer steps below the

mercury calibration point; this small displacement is an instrument-dependent constant known as

the 'offset' stored in the instrument Constants File, and is determined by the SC test).

If, however, the mercury calibration point falls outside the acceptance range, the micrometer is

reset to the newly calibrated step number and the test repeated. Iterations continue until the

calibration point converges correctly.