Pumps and accumulators, Identification and correction – Delta MMC120 User Manual

Page 70

Hydraulic System Problems

MMC120 Linear Motion Control Module

70

Delta Computer Systems, Inc. 360/254-8688

Pumps and Accumulators

Insufficient pump and/or accumulator capacity will cause the system response to degrade during a move

because the effective pressure drops.

Pressure transients due to insufficient accumulator volume cause jerky motion, particularly during starts and

stops. Note: Even systems with ‘fast’ pumps usually require at least a small accumulator near the cylinder to

maintain the constant pressure needed to get smooth motion.

Insufficient pump capacity can result in inadequate control when moving many axes simultaneously or when

making long moves. In these cases pressure can drop so much a fully open valve cannot maintain the

requested speed.

Identification and Correction

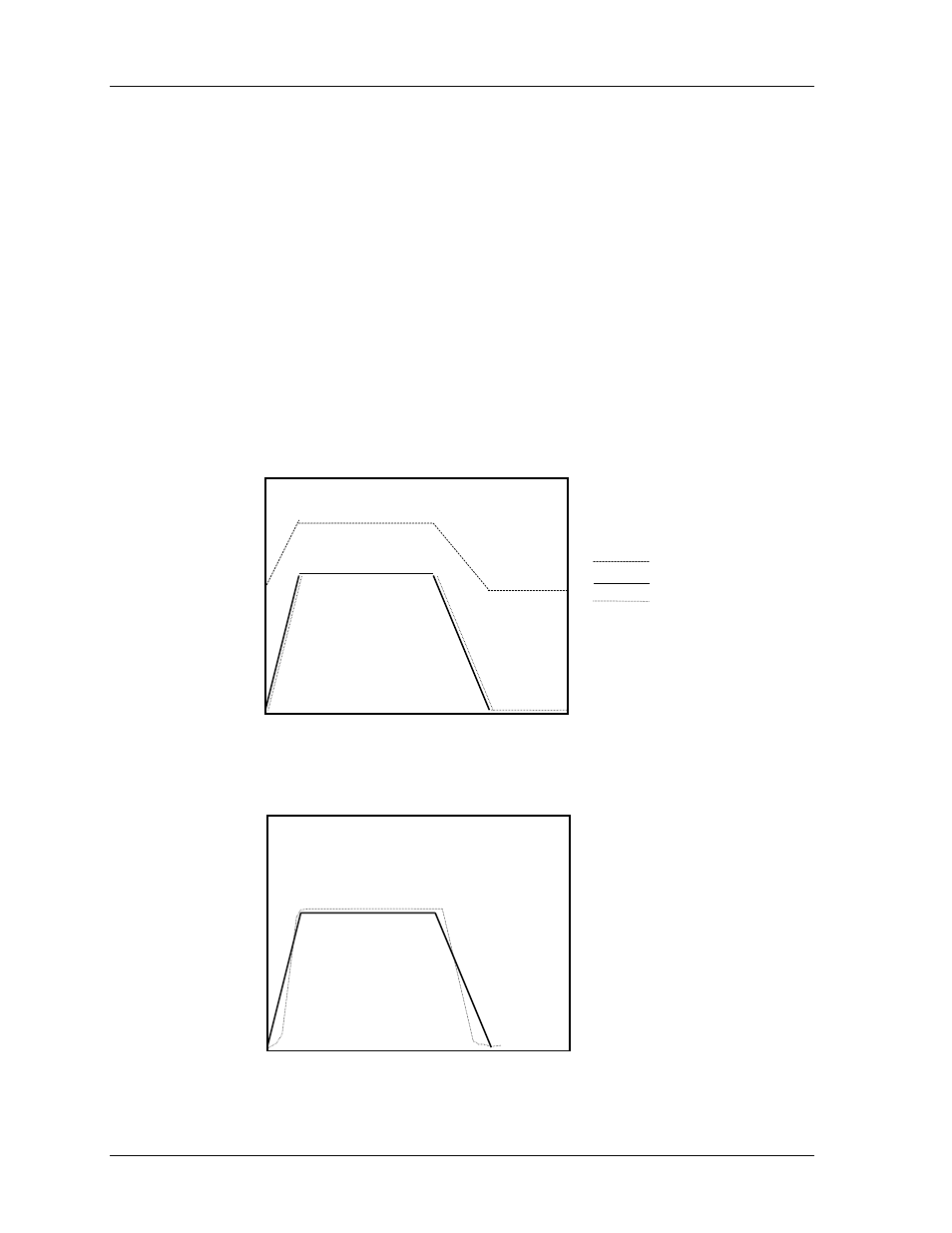

To identify and correct these problems, make a move with very low (or zero) gains except the FEED

FORWARD terms. Graph the move with DCS120. The graph (ignoring the Position terms) should show:

Drive (green)

Target Speed (purple)

Actual Speed (blue)

If the actual speed and target speed show:

Your valve probably has overlap. Replace the valve with a linear one or try increasing the DEAD BAND

ELIMINATOR value.