I/o register overview – Delta MMC120 User Manual

Page 48

Communicating with the MMC120

MMC120 Linear Motion Control Module

48

Delta Computer Systems, Inc. 360/254-8688

In addition to the parameter storage blocks, memory may be allocated for profile and event step storage if these

features are used.

Each profile requires four registers and each module can store up to eight profiles in the PLC's memory, for a

total of 32 registers. These first eight profiles can be changed from the PLC and another eight, for a total of

16, can be changed from DCS120. Only enough memory must be allocated to hold the profiles used in all the

modules in the system. The profiles consist of Mode, Acceleration, Deceleration, and Speed information.

If you use Event Control and want to store the step sequences in the PLC, you must reserve eight registers for

each step used. If you use all 256 event steps, you must reserve 2048 registers.

The demo program on the DCS120 disk shows an example of ladder logic for transferring parameters,

profiles, and Event Control steps to and from the MMC120.

I/O Register Overview

The MMC120 communicates with the Quantum Programmable Controller through four input (to the

programmable controller) and four output (to the MMC120) registers.

Input Registers

Output Registers

3TTTTT + 0

Axis 1 Status Bits

4TTTTT + 0

Axis 1 SAR/Command

3TTTTT + 1

Axis 1 Data In

4TTTTT + 1

Axis 1 Data Out

3TTTTT + 2

Axis 2 Status Bits

4TTTTT + 2

Axis 2 SAR/Command

3TTTTT + 3

Axis 2 Data In

4TTTTT + 3

Axis 2 Data Out

See page 46 for Output Register information and page 62 for Input Register information

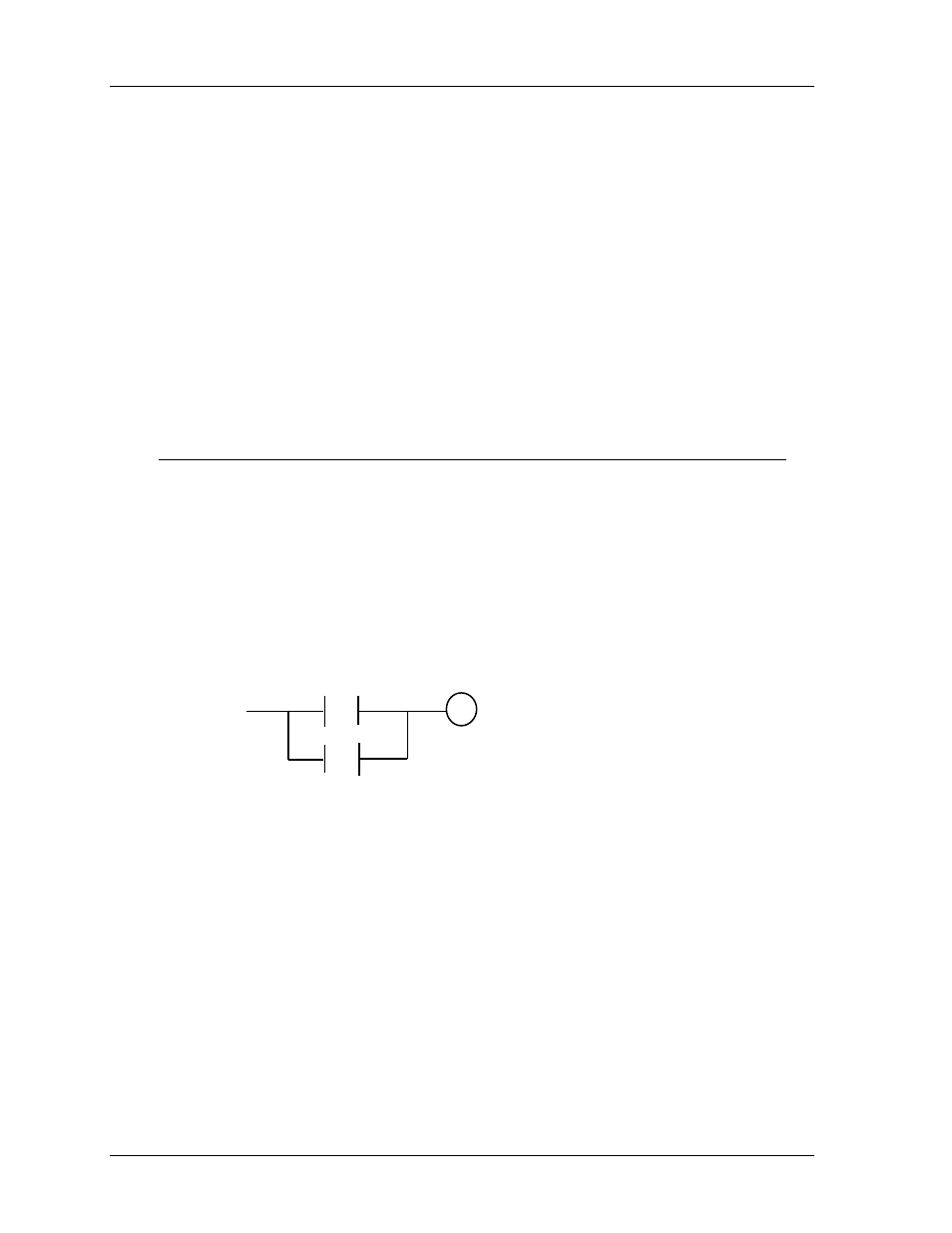

Whenever you issue a command to a module that changes the status area's definition, you must wait for the

ACK bit to toggle before reading the input registers. This guarantees that the data in the input registers is

valid. The following ladder logic will detect whenever the ACK bit changes state.

The MMC120 can accept commands as fast as the P/C can send them, but there could be as much as 2 ms of

latency before the MMC120 toggles the ACK.

I/O scan time must not be faster than segment scan. To keep data synchronized in a single-segment program,

round the minimum scan time up to the next 10ms boundary. For example, if your program has a 5 ms scan

time, set the minimum scan time to 10 ms; if it is 12ms, set the minimum to 20 ms.

P

N