Cooling & ventilating air – Generac Power Systems 53187 User Manual

Page 91

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

PART 3- ENGINE

LUBRICATION & COOLING SYSTEM

1

SECTION 3.3- COOLING

& VENTILATING AIR

Section 3.3

COOLING & VENTILATING AIR

General

Service technicians who work on the Series NP

(recreational vehicle) and IM (industrial mobile) gener

ators should be familiar with the air flow requirements

forthese units. Adequate air flow for cooling, ventilation

and engine combustion MUST be provided or serious

problems will result.

Types of Cooling Fans

Engine-generator sets may be equipped with either

(a) a PUSHER type fan, or (b) a SUCTION type fan.

The suction type (squirrel cage) fan may be Installed

on units with either a 10 or 15 inch stator. Pusher type

fans are used primarily on units having a 10 inch stator.

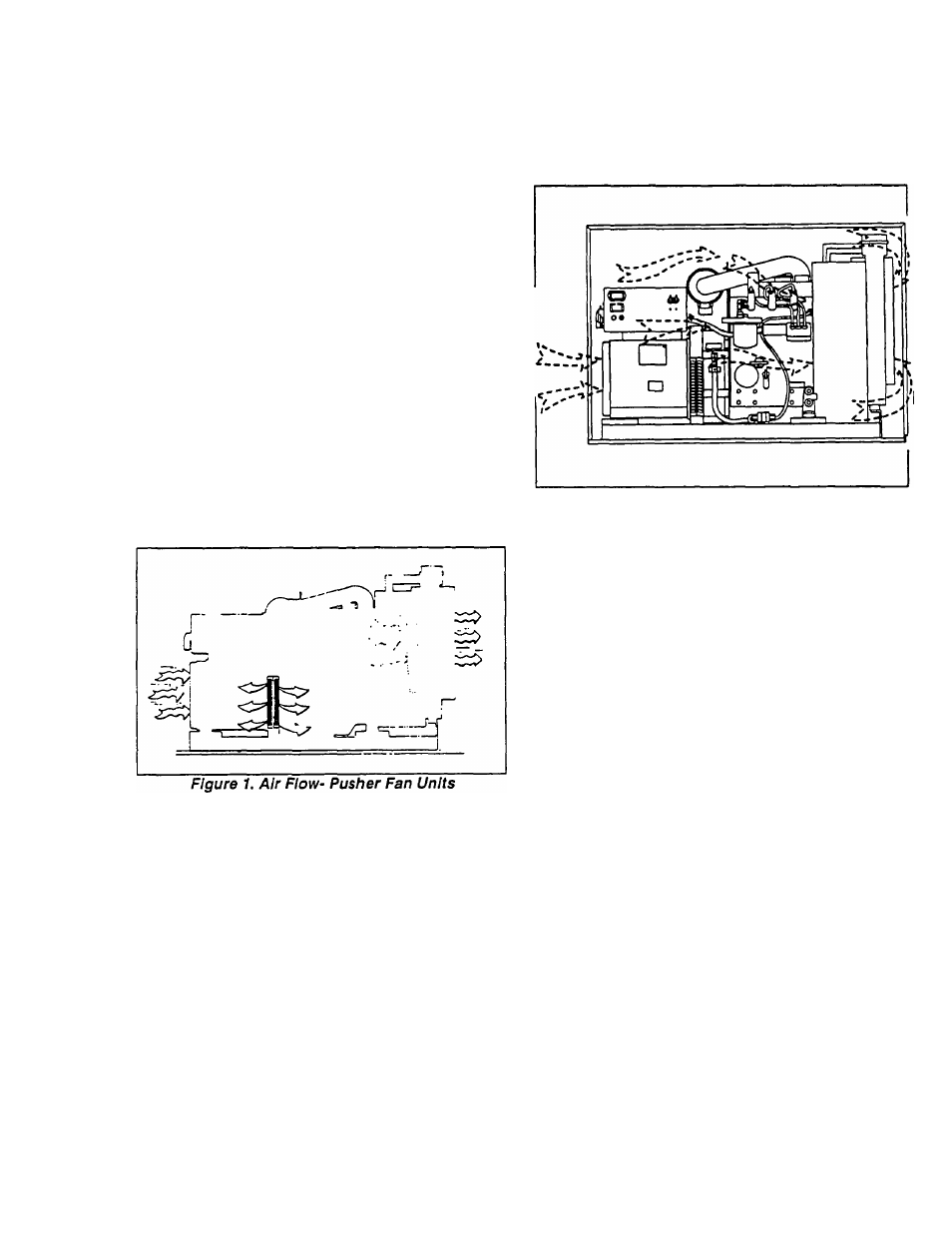

Air Flow- Pusher Fan Units

See Figure 1 below. A blower fan attached to the

generator rotor draws air into the generator interior to

cool generator internal parts. The heated generator

cooling air is expelled through a blower air outlet duct

on the side of the unit. The engine’s pusher fan draws

air around the generator, forces it through the radiator,

and outward, away from the unit.

Air Flow- Suction Fan Units

A centrifugal blower fan rotates with the generator

rotor to cool generator internal parts. The heated gen

erator cooling air is expelled outward through a blower

air outlet duct on the side of the generator.

The suction type fan is a high capacity 'squirrel

cage" type which draws air in, across the radiator, then

directs the air downward and away from the unit

through an air duct. See Figure 2.

Installation Manual

Additional information on cooling and ventiiating

requirements can be found in the 'INSTALLATION

MANUAL" for water-cooled recreational vehicle gener

ators.

Installation

Manuals

can

be

ordered

from

Generac Corporation.

Figure 2. Air Flow Suction Fan Units

Air Inlet- Suction Fan Units

When the engine-generator is installed in a com

partment (as in a recreational vehicle), the following

rules apply to air inlet openings in the compartment;

□ Ideally, the air inlet opening should be close to the

generator's rear bearing carrier. This will allow air to

circulate the full length of the compartment and

around the entire generator.

□ Unrestricted air inlet opening area must be at least

150 square inche (15 Inch stator units): or 300 square

inches (10 inch stator units).

□ If louvers, screening or expanded metal are used to

cover an air inlet opening, the restriction to air flow

offered by such materials must be compensated for.

This is done by making the actual air inlet opening

size proportionally larger.

Other Rules for Suction Fan Units

Some

installations

provide

a

compartment,

to

house the generator set. In some installations, a floor

less compartment or no compartment at all may be

P

rovided. The following rules apply:

I If a compartment is used, the unit radiator must not

contact the compartment wall. A minimum of at least

3-1/2 inches (90mm) of clearance is recommended

between the front and sides of the radiator and the

compartment walls. Such clearance is required so

the suction fan can draw air around the radiator

edges.

□ If a floorless compartment (or no compartment) is

used, the generator must be protected against road

splash and debris by such means as anti-splash

baffles.

PAGE 3.3-1