Generac Power Systems 53187 User Manual

Page 62

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

PART 2

ENGINE MECHANICAL

Engine Tolerances

MAIN REVOLVING SYSTEM (CONT’D);

Connecting Rod (Continued):

Connecting Rod to

Crankpin Oil Clearance

Allow able Lim it.................... 0.008 Inch

Connecting Rod

Bolt Torque ........................ 22-25 Ft.-Lbs.

Crankshaft:

Standard Diam eter of

Main Journal ...................... 1.8110 inch

Standard Tolerance of

Main Journal ...................... 1.8096-1.8100 Inch

Allow able Lim it of

Main Journal ...................... 1.7874 Inch

Main Journal Undersize_____ 0.010, 0.020 Inch

Cram kpln Standard

Diam eter ............................ 1.5354 Inch

Crankpin Standard

Tolerance............................ 1.5340-1.5344 inch

Allow able Crankping Lim it .. 1.5118 Inch

Crankpin Undersize.............. 0.010, 0.020 inch

Standard Crankshaft

Deflection........................... Less than 0.001 inch

Maxim um Allow able

Crankshaft Deflection .......... 0.002 inch

Standard Axial

Crankshaft Play................... 0.002 inch

Maxim um Allow able Axial

Crankshaft Play................... 0.020 inch

Standard Thickness of

Thrust W asher..................... 0.079 inch

Standard Tolerance

of Thrust W asher................. 0.077-0.079 inch

Maxim um Allow able Thickness

of Thrust W asher................. 0.071 inch

Tolerance of Oil Clearance

Betw een Crankshaft Journal

and Center Bearing.............. 0.0015-0.0036 Inch

Maxim um Allow able Oil

Clearance Betw een Crankshaft

Journal and Center Bearing . 0.0078 Inch

VALVE SYSTEM:

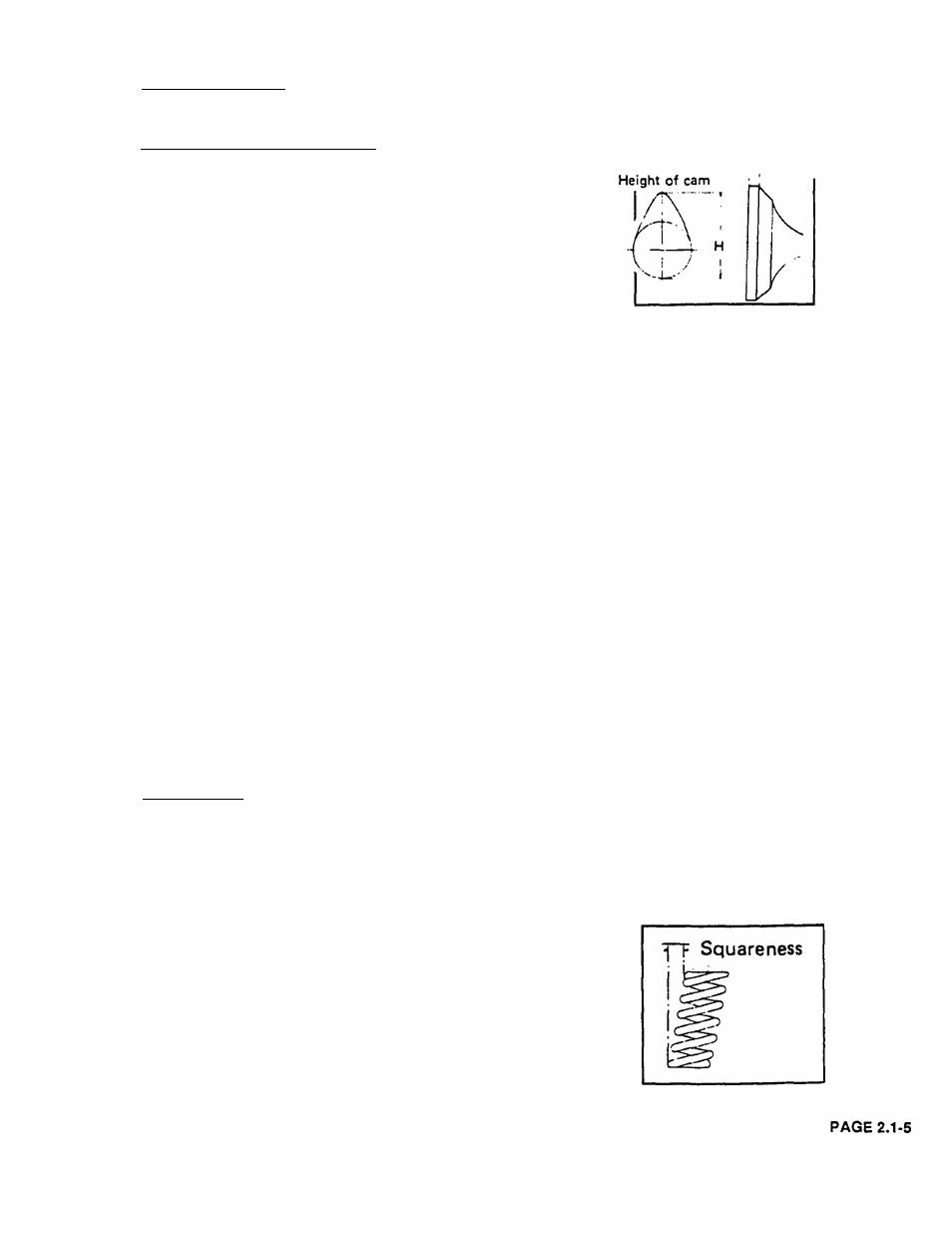

Cam shaft:

Standard Height of Cam

Tolerance for Intake &

Exhaust............................... 1.0413-1.0433 inch

Minim um Allow able Cam Height

for Intake & Exhaust ............ 1.0276 Inch

Standard Cam Height

for Injection Pum p............... 0.9425-0.9472 inch

Minim um Allow able Injection

Pum p Cam Height................ 0.9370 inch

Standard Cam Height for

Feed Pum p ......................... 1.0590-1.0630 inch

Minim um Alow able Cam Hieght

for Feed Pum p..................... 1.0236 Inch

Standard Cam Gear

Backlash ............................. 0.003 Inch

Maxim um Cam Gear

Backlash .............................0.012 inch

SECTION 2.1

ENGINE SPECIFICATIONS & CHARTS

and Fits (Continued)

^ “ (thickness)

Valves:

Standard Diam eter of

Intake Valve Stem ................ 0.

Maxim um Allow able Diam eter

of Intake Valve Stem ............. 0.

Standard Diam eter of

Exhaust Valve Stem .............. 0.

Maxim um Allow able Diam eter

of Exhaust Valve Stem ...........0,

Standard Clearance Betw een

Intake Valve Stem and Valve

Guide..................■ ............... 0.

Maxim um Clearance Betw een

Intake Valve Stem and Valve

Guide.................................. 0,

Standard Clearance Betw een

Exhaust Valve Stem and

Guide...................................0

Maxim um Clearance Betw een

Exhaust Valve Stem and

Guide...................................0

Valve Standard Thickness .. 0

Valve Thickness Standard

Tolerance.............................0

Maxim um Allow able Valve

Thickness............................. 0

Valve Clearance- Intake &

Exhaust (W hen Cold).............0

2744-0.2738 Inch

2713 inch

2740-0.2736 Inch

2693 inch

001-0.002 inch

,0079 inch

.0016-0.0026 inch

.010 Inch

.039 inch

.036-0.042 inch

,020 Inch

.008-0.020 inch

Valve Springs:

Force Required to Com press

Springs to a Length of 1.197

inch.....................................17.86 pounds

Valve Spring Standard

Free Length......................... 1.3779 Inch

Valve Spring Minim um

Free Length......................... 1.3189 Inch

Standard Valve Spring

Squareness ..........................Less than 0.047 inch

Replace Spritig if Out-of-

Square More Than................. 0.079 Inch