Part 2 engine mechanical – Generac Power Systems 53187 User Manual

Page 71

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

SECTION 2.4

DISASSEMBLY AND INSPECTION

i

PART 2

ENGINE MECHANICAL

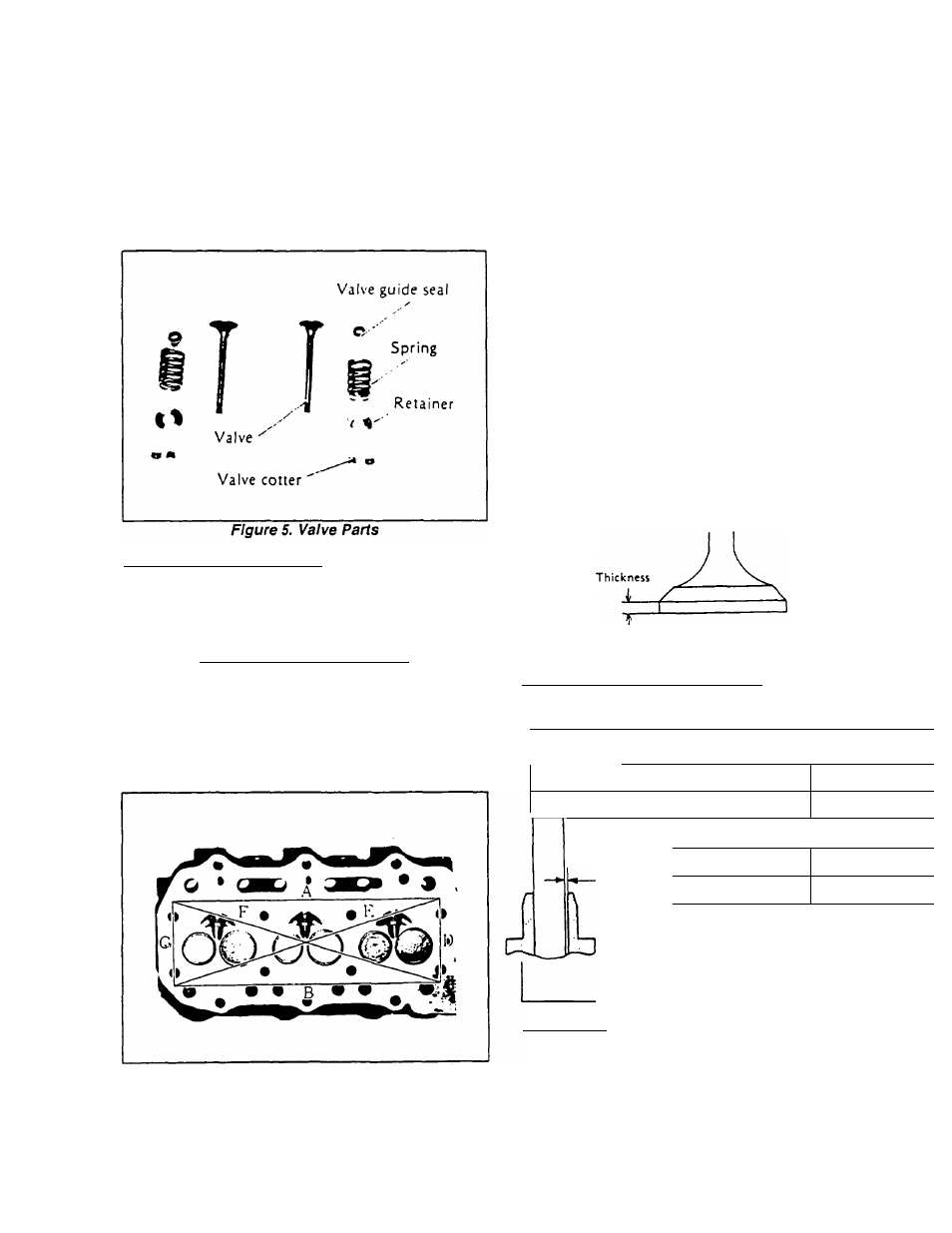

VALVE PARTS:

Cylinder Head Assembly

VALVE STEM :

Use a valve spring com pressor to com press the

SPRINGS. Then, rem ove the VALVE COTTER. RE

TAINER,

SPRING

and

VALVE.

Also

rem ove the

VALVE GUIDE SEAL.

CHECK CYLINDER HEAD W ARP:

Use a straight edge and a thickness gauge to check

w arpage on the cylinder head low er face. Check w ith

the straight edge at six (6) points, as show n in Figure

6. If w arped excessively, correct w ith a surface grinder.

MAXIMUM CYUNDER HEAD W ARP

STANDARD VALUE - LESS THAN 0.0020 INCH

REPAIR IF MORE THAN 0.005 INCH

Inspect valve stem for dam age and excessive

w ear. Replace if dam aged or w orn excessively. Use a

m icrom eter to check valve stem diam eters at locations

1,11 and III (Figure 7). If the stem is w orn beyond lim its,

replace the valve. Also check valve head thickness

(Figure 7), replace valve if w orn excessively.

Intake Valve:

Standard Diameter

0.2740-0.2744 inch

(6.955-6.97mm)

Allowable Limit

0.24 inch (6.09mm)

Exhaust Valve

Standard Diameter

0.2736-0.2740 Inch

(6.95-6.96mm)

Allowable Limit

0.2693 inch (6.84mm)

Stem end

i/^

D

Thickness of Valve Head

Standard Thickness

0.036-0.042 inch

(0.925-1.075mm)

Allowable Limit

0.0197 inch (0.5mm)

Figure 7. Valve Stem and V alve Head Inspection

VALVE TO VALVE GUIDE CLEARANCE:

Check clearance betw een valve and valve guide

(Figure 8). If beyond lim its, replace w orn parts.

Intake valve

1

/—

Standard clearance

Allowable limit

0.03 to 0.06 mm

0.2 mm

Exhaust valve

Clearance

Standard clearance

Allowable limit

0.04 to 0.065 mm

0.25 mm

Figure 6. Check Points for Cylinder Head Warp

Figure 8. Valve to Valve Guide Clearance

VALVE SEAT:

Alw ays check

for

valve guide w ear before correct

ing valve seat. Use 15‘, 45' and 75" cutters to correct

the valve seat (Figure 9).

PAGE 2.4-2