Engine reassembly – Generac Power Systems 53187 User Manual

Page 80

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

PART 2

ENGINE MECHANICAL

i

SECTION 2.5

ENGINE REASSEMBLY

Section 2.5

ENGINE REASSEMBLY

General

This section provides instructions for the reassem

bly of the engine. Be sure to w ash all parts prior to

reassem bly. In addition, be sure to coat all sliding and

rotating surfaces w ith fresh, clean, new engine oil. Such

surfaces as cylinder bores, pistons, bearings, bearing

surfaces, etc., should be liberally coated w ith oil. Use

new gaskets, seals and o-rings. Alw ays tighten bolts to

the recom m ended tightness. Never overtighten any

fasteners that thread into alum inum .

Relief Valve

See Figure 16 on Page 2.3-4. Install a new o-ring

onto the relief valve assem bly. Install the relief valve

and tighten to the recom m ended torque.

RELIEF VALVE TORQUE

43-61 Ft-Lbs. m-kg)'

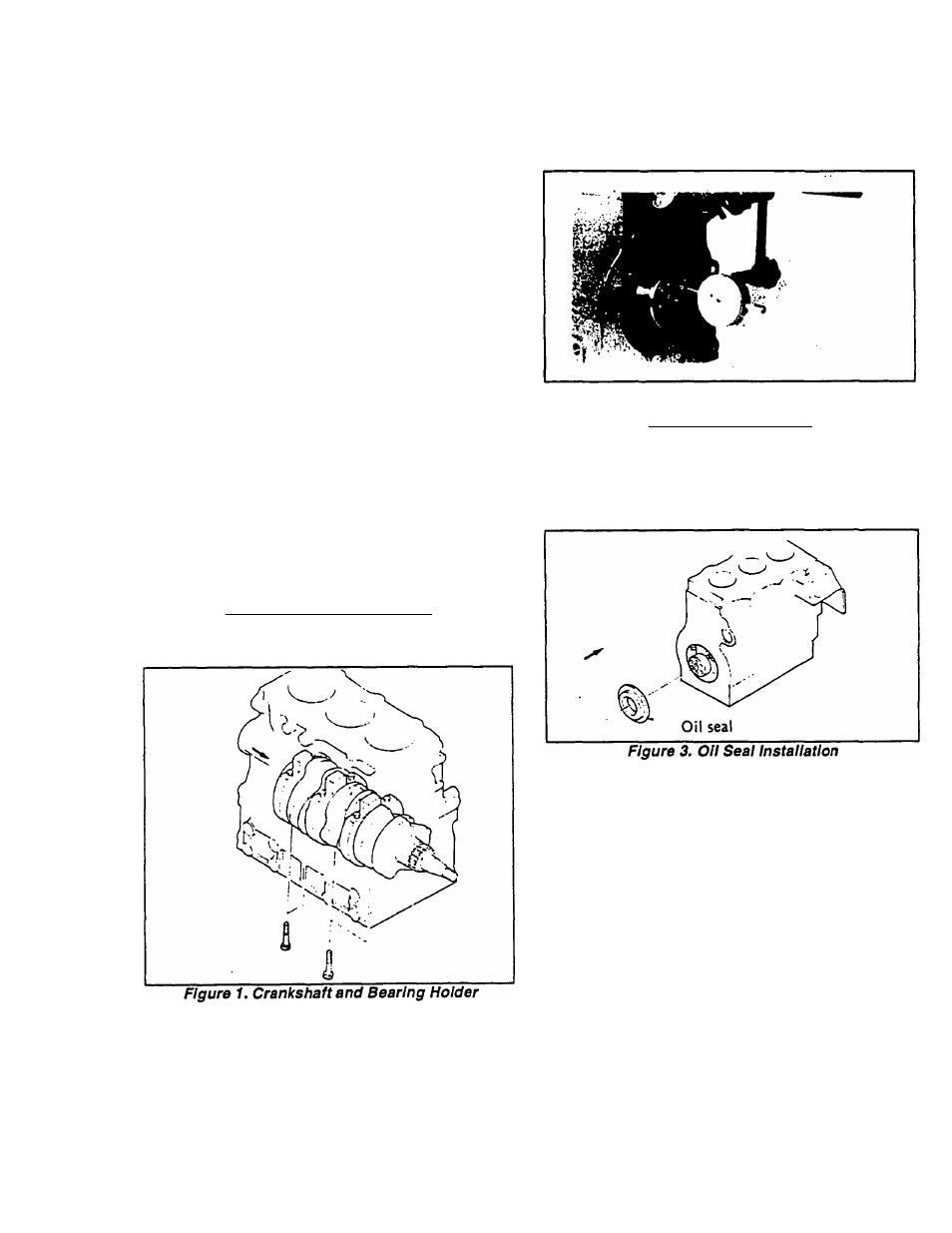

Crankshaft and Bearing Holder

1. Instali bearing holder onto crankshaft and into bush

ing at front of cylinder block.

2. Align bolt holes at low er part of cylinder block w ith

threaded holes on bearing holder, install and tighten

bolts. Use tw o hex head bolts at flyw heel side.

BEARING HOLDER TORQUE

18-22 Ft.-Lbs. (2.S-3.0 m-kg)

3. Measure the crankshaft end play, in the direction of

the crankshaft.

Figure 2. Cheeking Crankshaft End Play

CRANKSHAFT END PLAY

Standard = 0.0020-0.0118 inch (0.05-0.30mm)

Allowable Limit = 0.020 Inch (O.Smm)

4. Install oil seal at flyw heel end of crankshaft (Figure

3).

5. Install flyw heel cover. Spread liquid packing over the

M10 screw hole of the cylinder block flyw heel cover

face (Rgure 4), then fit the flyw heel over it.

FLYWHEEL

TIGHTENING

TORQUE

—34-40Tt:-Lb8. (4.T-S.S

m-kgj—

6. Install the flyvyheel. Pay close attention to location of

the alignm ent pin. Retain flyw heel w ith bolts and lock

ring. See Figure 5.

FLYWHEEL TIGHTENING TORQUE

43-Si Ft.-Lbs. (6-y m-ltg)

PAGE 2.5-1