Introduction to dc control systems – Generac Power Systems 53187 User Manual

Page 107

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

PARTS

ENGINE ELECTRICAL SYSTEM

1

SECTION 5.1

INTRODUCTION TO DC CONTROL SYSTEMS

Section 5.1

INTRODUCTION TO DC CONTROL SYSTEMS

General

Several different variations of the engine DC con

trol system have been employed on the NP and IM

series generators. These variations depend on (a) the

date the engine control circuit board was manufac

tured, and (b) the type of starter used to crank the

engine. To avoid confusion between these system vari

ations, this manual arbitrarily identifies the DC control

system as Type 1, Type 2 or Type 3.

TYPE 1 DC CONTROL SYSTEM;

The Type 1 DC control system applies to units

having

an

earlier

production

engine

control

circuit

board. These early circuit boards required that a crank

relay (CR1) and a run relay (CR2) be employed to

deliver operating power to the board during cranking

and running, and to open the power circuit to the board

for shutdown. Only the Type 1 system employs Relays

CR1 and CR2.

The engine starter (Part No. 70954) used on these

units is NOT equipped with a pull-in type starter sole

noid. A starter contactor (SC) is used to deliver cranking

current to the starter motor.

TYPE 2 DC CONTROL SYSTEM;

Type 2 DC control systems utilize an improved

engine control circuit board. The crank (CR1) and run

(CR2) relays that were used in Type 1 systems are not

required, since the circuit board has taken over the

function of the relays.

Like the Type! systems, the engine starter (Part

No. 70954) is NOT equipped with a pull-in type starter

solenoid. A starter contactor (SC) is used to deliver

cranking current to the starter motor.

TYPE 3 DC CONTROL SYSTEM:

The same improved engine control circuit board

that is used on Type 2 systems is used on the Type 3

system. Crank relay (CR1) and run relay (CR2) are not

used.

The engine starter on Type 3 units IS equipped with

a pull-in type starter solenoid. A single starter relay (SR)

is employed to energize the starter-mounted solenoid

and initiate cranking.

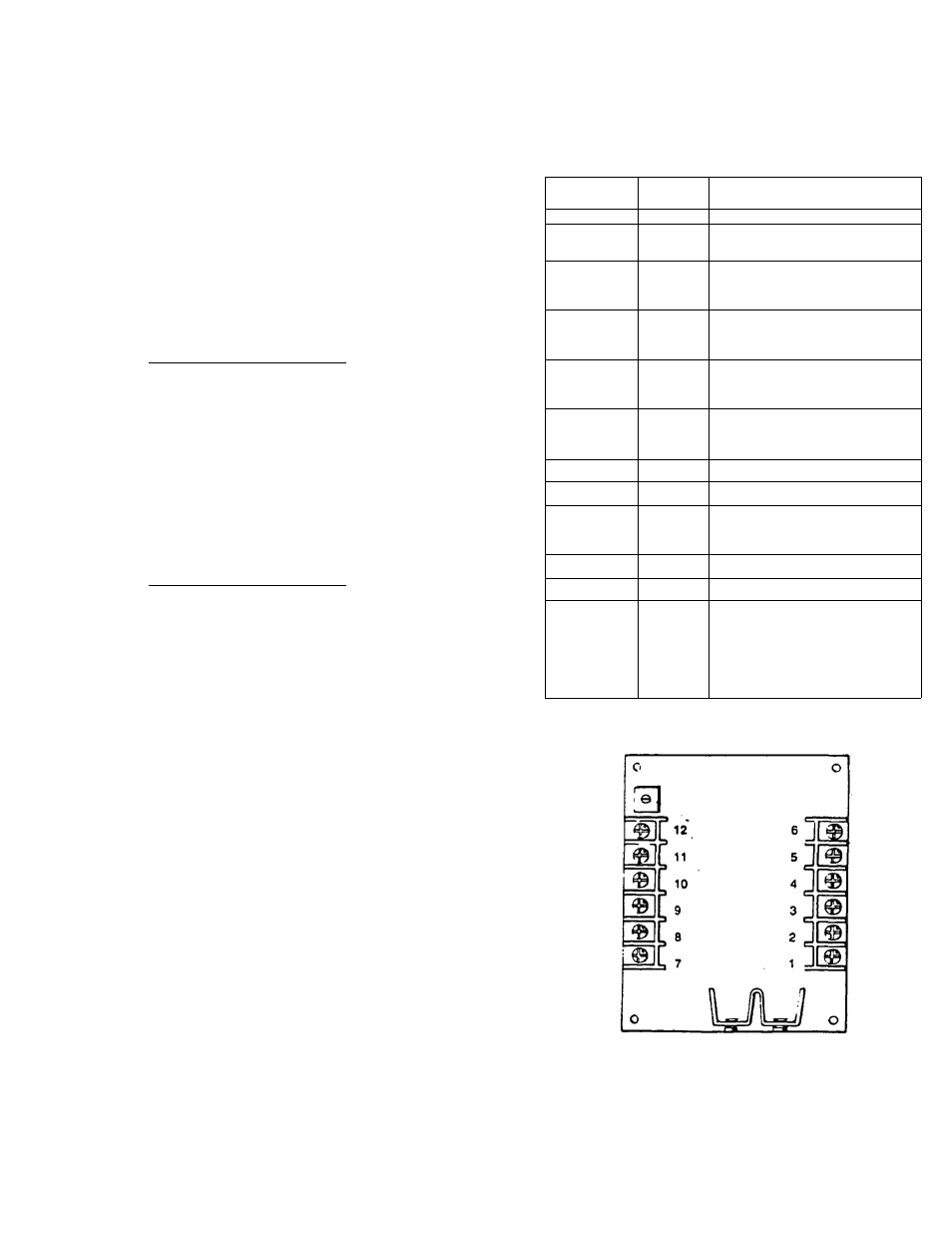

Engine Control Circuit Board

The engine control circuit board Is the electronic

control center for engine cranking, starting, running and

shutdown operations. The circuit board is housed in the

generator control panel. Two terminal strips are pro

vided on the board, with terminals numbered from 1

through 12. See Rgure 1.

The circuit board is powered by 12 volts DC from

the unit battery. Functions of the various terminals are

listed in the following chart.

TERMINAL

WIRE

FUNCTION OF CIRCUIT

1

Fused battery voltage (■•■)

2

0

Battery negative (grounded)

side of power supply circuit

3

17,17A

Start circuit. Initiates startup

when start/stop switch is

set to "Start"

4

18

Shutdown circuit, initiates

shutdown when start/stop

switch Is set to "Stop"

5

11

Engine speed (frequency)

signal for overspeed

shutdown

6

22

Engine speed (frequency)

signal for overspeed

shutdown

7

56

Engine cranking circuit

8

9

DC voltage to field boost

9

14

Engine run circuit Is

energized when engine is

running

10

14

Same as Terminal 9

11

14

Same as Terminal 9

12

85

Provides automatic shut

down when circuit Is

grounded by closure of

low oil pressure switch or

high coolant temperature

switch

Figure 1. Engine DC Control Circuit Board

PAGE 5.1-1