Disassembly and inspection, General, Rocker arm assembly – Generac Power Systems 53187 User Manual

Page 70

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

PART 2

ENGINE MECHANICAL

1

SECTION 2.4

DISASSEMBLY AND INSPECTION

Section 2.4

DISASSEMBLY AND INSPECTION

General

Before starting the disassem bly and Inspection pro

cedure, check the folow ing:

GCarefully Inspect the cylinder block and cylinder

head for dam age and evidence of w ater leakage.

DUse pressure air to blow out all oil holes, m ake sure

none of the holes are plugged.

□w ash al parts to rem ove dirt, dust, dirty oil and

carbon deposits.

□clean all carbon deposits from the piston, cylinder

head and valves. Make sure these parts are not

dam aged. Pay special attention to alum inum alloy

parts.

□Place m atch m arks on m ating parts for correct

reassem bly.

Rocker Arm Assembly

Rem ove bolt at end of rocker arm shaft. Rem ove

ROCKER

ARM,

ROCKER

ARM

BRACKET

and

springs. Pull out the spring pin from from the No. 1

cylinder ROCKER ARM BRACKET. Rem ove ROCKER

ARMS, SPRINGS and BRACKETS.

Rocker arm

\y'

Rocker arm bracket

Figure 1. Rocker Arm s and Rocker Arm Brackets

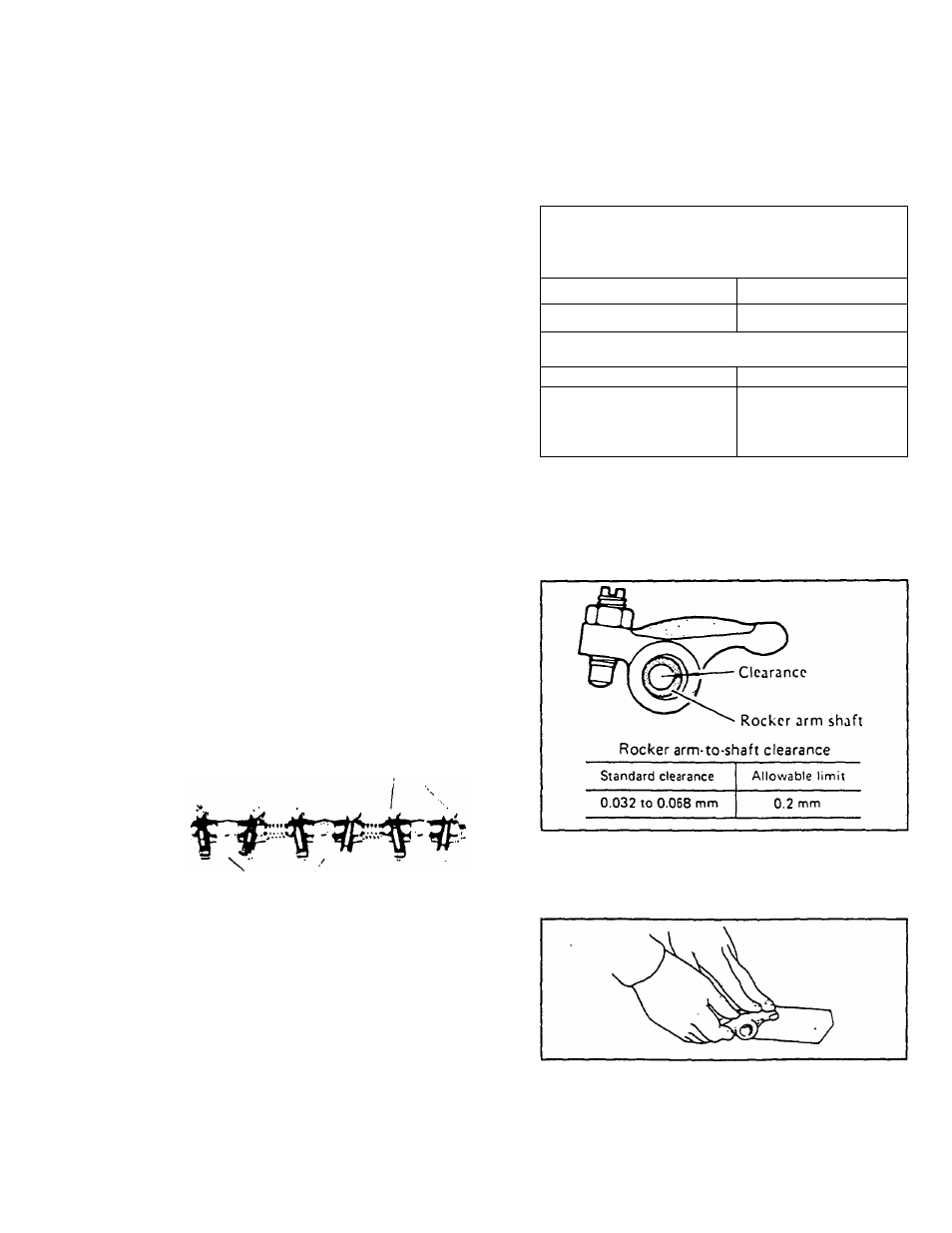

Use a m icrom eter to check the outside diam eter of

the rocker arm shaft If allow able lim its are exceeded,

replace the rocker arm shaft.

W ear of rocker arm shaft!

o )

Standard dimension

Allowable limit

11.65 to 11.67 mm

11.57 mm

■ i______ ^^__________ 1______ 1

]_

1/ _ ^ “

I 1 I

t 1 t

Figure 2. W ear Lim its of Rocker Arm Shaft

Measure the inside diam eter of the

rocker arm .

Cal

culate the clearance betw een the rocker arm and the

rocker arm shaft. If allow able lim its are exceeded,

replace the part(s).

Figure 3. Rocker Arm to Shaft Clearance

Check the valve stem face for step w ear or scoring.

Slight

w ear or

scoring

m ay

be corrected using an oil

stone or grinder (Figure 4).

Figure 4. Removing Slight Wear or Scoring

PAGE 2.4-1