Operational tests and adjustments, Parti the revolving field ac generator – Generac Power Systems 53187 User Manual

Page 53

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

PARTI

THE REVOLVING FIELD AC GENERATOR

1

SECTION 1.9

OPERATIONAL TESTS & ADJUSTMENTS

Section 1.9

OPERATIONAL TESTS AND ADJUSTMENTS

Introduction

Follow ing m ajor m aintenance, an operational test

of the generator should be conducted. Any required

adjustm ents should be com pleted at this tim e. Opera

tional testing m ay be accom plished on either an in

stalled or uninstalled generator.

Preparation Before Operation

Before you attem pt to crank or start the generator,

be sure to check the follow ing:

□ Check engine oil level.

□ Check engine coolant level.

□ Check fuel supply.

□ Check cooling air flow .

CHECK ENGINE OIL LEVEL:

Rem ove the engine dipstick and w ipe end w ith a

clean, lint-free cloth. Insert dipstick again and check oil

level. Add the recom m ended oil, if necessary, to the

dipstick

"FULL"

m ark

only.

DO

NOT

OVERFILL

ABOVE THE "FULL" MARK. NEVER OPERATE THE

ENGINE

W ITH

OIL

LEVEL

BELOW

THE

"ADD"

MARK.

Engine oil capacity w ithout oil filter change is 3.7

U.S. quarts; w ith oil filter change, capacity is 4.0 U.S.

quarts.

Use a high quality detergent oil classified "For

Service CC or CD". Detergent oils keep the engine

cleaner and reduce carbon deposits. Use oil having the

follow ing SAE (Society of Autom otive Engineers) vis

cosity rating, based on the am bient tem perature range

anticipated before the next oil change:

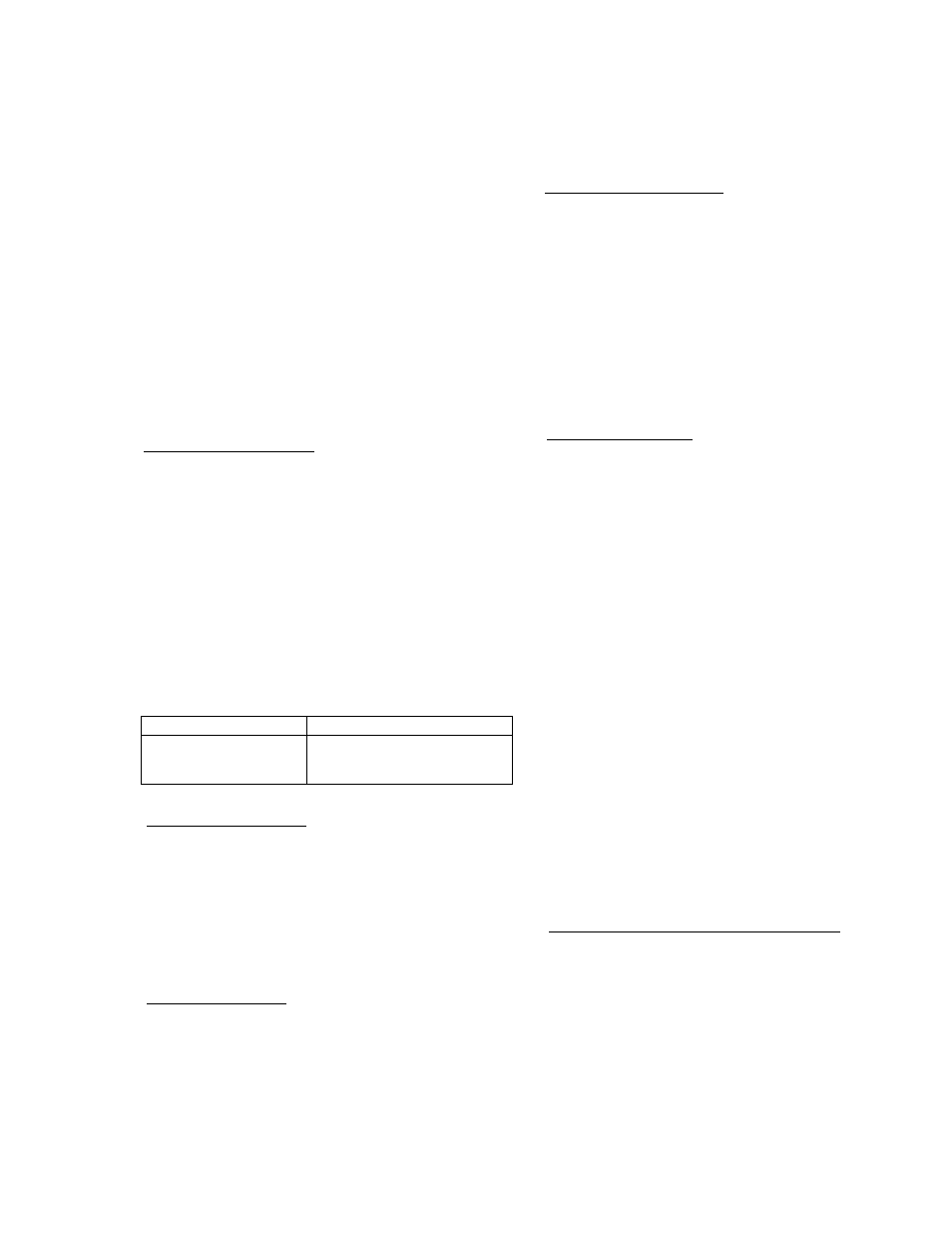

AMBIENT TEMPERATURE

RECOMMENDED SAE VISCOSITY

Above 100’ F.

40MOO' F.

Below 40‘ F.

Use SAE 4tTo1l

SAE10W-30orSAE30 0ll

SAE SW-20 or SW-30 Oil

CHECK COOLANT LEVEL:

Som e generator m odels w ill be equipped w ith a

rem ote m ounted radiator, som e m odels w ith a unit-

m ounted radiator. Before starting, be sure to check the

coolant level in the radiator as w ell as the coolant

recovery bottle.

Recom m ended coolant is a 50-50 m ixture of ethyl

ene glycol base anti-freeze and soft w ater. Use only a

low silicate type anti-freeze. W hen adding coolant,

alw ays add the recom m ended 50-50 m ixture.

CHECK FUEL SUPPLY:

Recom m ended fuel is a high quality, autom otive

type DIESEL fuel conform ing to JIS No. 2D diesel fuel.

The fuel supply m ust be kept CLEAN.

CHECK COOLING AIR FLOW ;

If the generator is installed, m ake sure all cooling

air inlet and outlet openings are open and unot^

staicted. W ithout adequate cooling air flow , the unit w ill

quickly overheat and cause problem s.

Starting the Engine

Before startup, turn OFF all electrical loads. Initial

tests and adjustm ents are accom plished w ith the unit

at no-load. To crank and start engine, hold the engine's

startfstop sw itch at START. Release the sw itch w hen

the engine starts. Let the engine stabilize and w arm up.

Operational Tests

PRELIMINARY CHECKS:

W hen the engine has stabilized and w arm ed up,

check all gauge and instrum ent readings available (oil

pressure, coolant tem perature, DC voltm eter, AC volt

age, AC frequency).

NO TE: Som e Installations m ay Include a gauge and

m eter panel. See Part S, Section 5.8, "REM OT E

PANELS AND CABLES".

Listen to the engine-generator w hile it is running.

Unusual noises should be investigated and corrected.

If the exhaust system is defective, shut dow n and

com plete the necessary repairs.

DANGER:

ENGINE

EXHAUST

GASES

CONTAIN

DEADLY

CARBON

MONOXIDE

GAS.

CARBON

MONOXIDE

IS

AN

ODORLESS

AND

COLOR

LESS

GAS

THAT

IS

FORMED

DURING

THE

COMBUSTION

OF

HYDROCARBON

FUELS.

DO

NOT OPERATE THE GENERATOR IF ITS EX

HAUST

SYSTEM

IS

DAMAGED

OR

LEAKING.

EXHAUST

FUMES,

IF

BREATHED

IN

SUFFI

CIENT

CONCENTRATIONS,

CAN

CAUSE

UN

CONSCIOUSNESS

OR

EVEN

DEATH.

PROVIDE

ADEQUATE

VENTILATION

TO

PREVENT

THIS

DANGEROUS GAS FROM ACCUMULATING.

Inspect the engine carefully for signs of oil, fuel or

coolant leaks. No leakage should be perm itted.

CHECK AC OUTPUT VOLTAGE & FREQUENCY:

W ith the engine running at no-load, use an accu

rate AC voltm eter and frequency m eter to check volt

age and frequency output. Record all readings for

future reference. Frequency should bo 60.5-63.5 Hertz.

Line-to-neutral voltage should be 121-127 volts AC;

line-to-line voltage should be 242-254 volts AC at no-

load. Setting the no-load frequency slightly high helps

S

revent excessive rpm and frequency droop under

eavy electrical loading.

PAGE 1.9-1