Generac Power Systems 53187 User Manual

Page 81

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

SECTION 2.5

ENGINE REASSEMBLY

1

Crankshaft & Bearing Holder (Continued)

Liquid packing

Figure 4. Liquid Packing

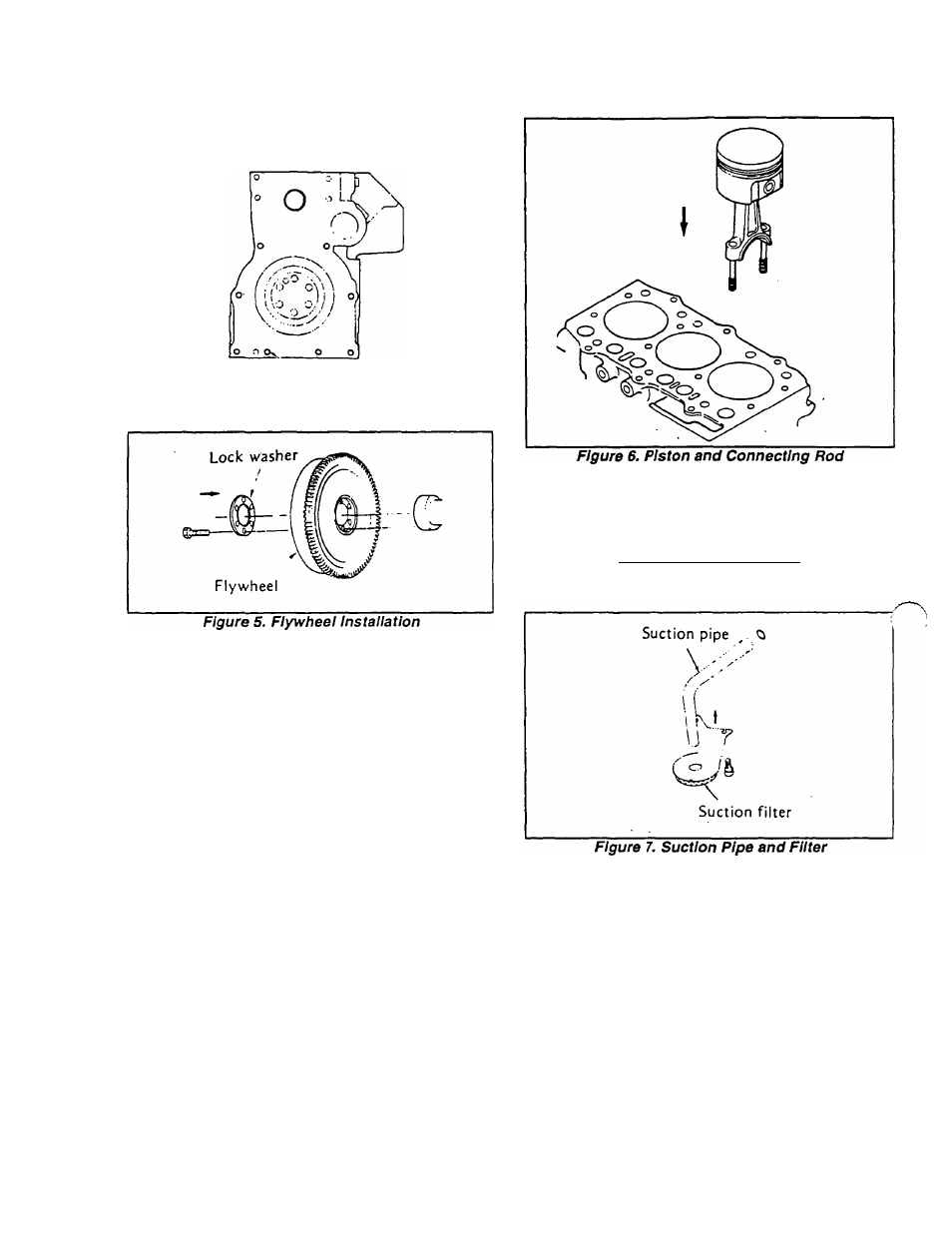

Piston and Connectinq Rod

1. Coat parts w ith clean engine oil. Move the piston

rings around to provide plenty of oil in the ring grooves.

2. Set the ring gaps 90' apart from each other. How

ever, do NOT place the ring gaps tow ard the piston pin

or at right angles to the piston pin.

3. Use a ring com pressor to com press the rings around

the piston.

4. Face the alignm ent m ark on the connecting rod

tow ard the injection pum p. Install the parts, starting at

the front and m oving tow ard the rear.

5. Tighten the connecting rod caps to their specified

torque.

CONNECTING ROD CAP TIGHTNESS

22-25 Ft.-Lbs. (3.0-3.5 m -kg)

6. After installation, check that the crankshaft can m ove

slightly the specified axial distance.

CRANKSHAFT

AXIAL

PLAY

0.004-0.012 Inch (0.1-0.3m m )

PART 2

ENGINE MECHANICAL

Suction Pipe and Filter

Install an o-ring onto the suction pipe. Install the

pipe into the cylinder block. Install the suction filter.

SUCTION FILTER TIGHTNESS

7-9 Ft.-Lbs. (0.9-1,3 m -kg)

Oil Pan

Tighten oil pan boltsevenly and in diagonal incre

m ents. Install the front plate.

Camshaft Assembly

Install the cam shaft assem bly ana plate. Tighten

the plate to the specified torque. See Figure 8.

PLATE TIGHTENING TORQUE

7-9 h.-Lbs. (0.9-1.3 m -kg)

PAGE 2.6-2