Generac Power Systems 53187 User Manual

Page 84

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

PART 2

ENGINE MECHANICAL

Cylinder Head Assembly (Continued)

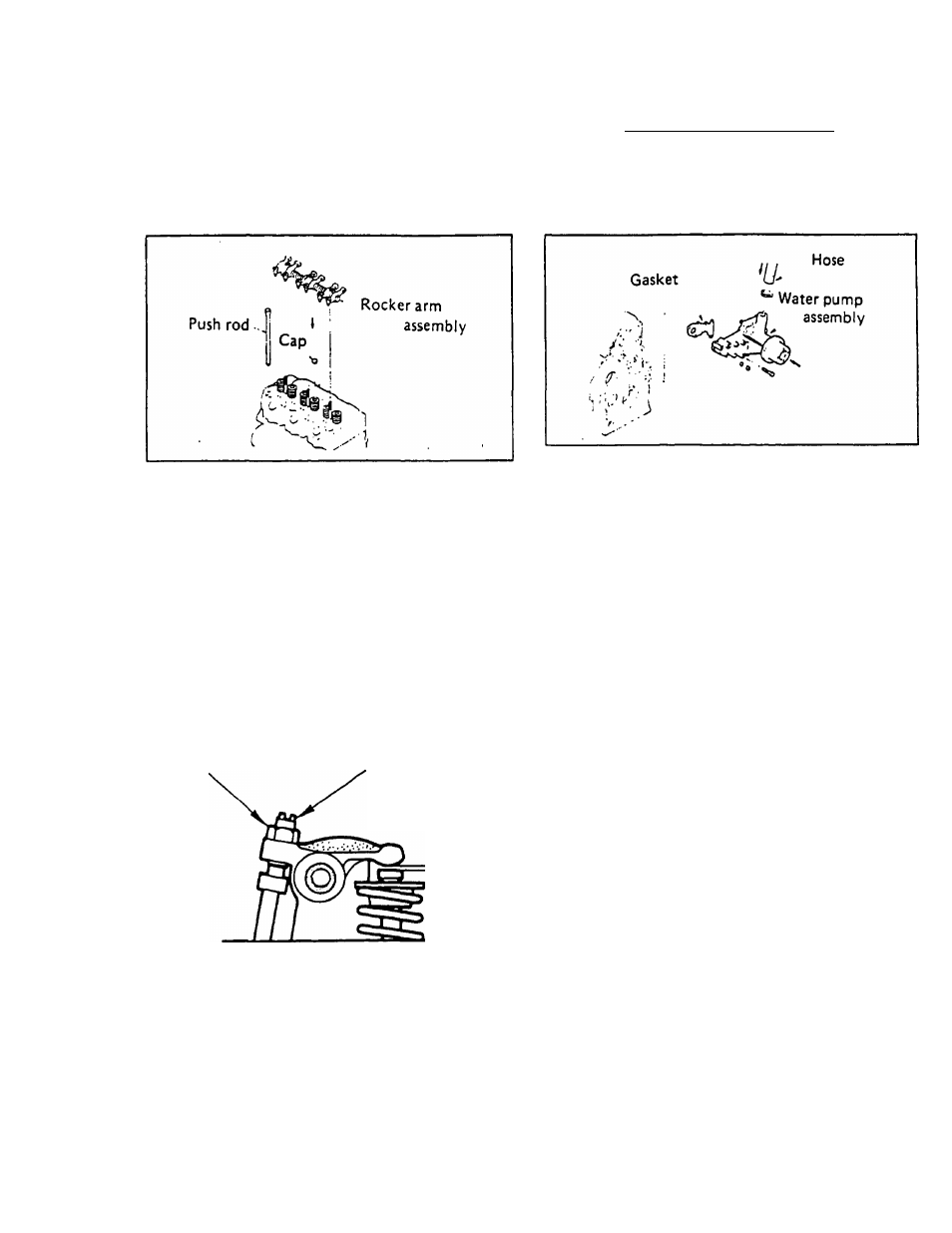

4. Install CAPS on end of valve stem s. Install the PUi

RODS and the ROCKER ARM ASSEMBLY.

SH

ROCKER ARM TIGHTENING TORQUE

15-18 Ft.-Lbs. (2.0-2.5 m -kg)

Figure 17. Caps, Push Rods, Rocker Arm

Valve Clearance Adjustment

See Figure 18. Loosen the NUT, then adjust intake

and exhaust valve clearance to 0.008 inch (0.2m m ) by

turning the ADJUST SCREW . Use the follow ing proce

dure:

1. Adjust valve clearance w ith engine cold.

2. Set No. 1 pistonattopdeadcenter(TDC). then adjust

the intake and exhaust valves of No. 1 cylinder and the

exhaust valve of No. 2 cylinder.

3. Turn the crankshaft 240* counterclockw ise (as

view ed from the front).

4. Adjust No. 3 cylinder intake and exhaust valves and

the intake valve of No. 2 cylinder.

Nut

Adjust screw

Valve clearance

1

SECTION 2.5

ENGINE REASSEMBLY

CYLINDER HEAD COVER TORQUE

6-8 Pt.-Lbs. (0.8-1.2 m -kg.)

Water Pump Assembly

Install the w ater pum p assem bly, gasxet and hose.

Figure 19. W ater Pum p, Gasket & Hose

Nozzles and Nozzle Holders

Install caps and gaskets. Install nozzle holders and

tighten to specified torque. Install the return pipe and

the injection pipes, tighten to specified torque.

NOZZLE HOLDER TIGHTENING TORQUE

58-61 Ft.-Lbs. (8.0-8.5 m -kg)

INJECTION PIPE TIGHTENING TORQUE

18-22 Ft.-Lbs. (2.5-3.0 m -kg)

Complete the Assembly

Install any rem aining engine com ponents.

Figure 18. Adjusting Valve Clearance

Cylinder Head Cover

Install cover gasket and cover. Tighten the cover evenly

to recom m ended torque.

PAGE 2.5-5