Preheat system – Generac Power Systems 53187 User Manual

Page 119

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

PARTS

ENGINE ELECTRICAL SYSTEM

SECTION 5.4

PREHEAT SYSTEM

Section 5.4

PREHEAT SYSTEM

Introduction

The generator control panel m ounts a PREHEAT

sw itch. W ^hen actuated, this sw itch turns on a glow plug

in each engine cylinder. The glow plug acts as a heating

elem ent to w arm the engine com bustion cham bers and

provide quicker, easier starts in cold w eather.

To w arm the engine com bustion cham bers and

provide quicker cold w eather startup, push the panel

PREHEAT sw itch in and hold for about 15-30 seconds.

DO NOT EXCEED 30 SECONDS PREHEAT TIME.

NO TE: A PREHEAT sw itch Is also Included on the

optional

rem ote-m ounted

start/stop

panels.

See

Section 5.7 (Part 5, Section 5.7).

Units with Time 1 DC Control System

a ly

Units w ith a Type 1 DC control system are

equipped w ith a crank relay (CR1) and a run relay

(CR2). The crank relay (CR1) rem ains energized only

w hile the start/stop sw itch is held at its *Starf position

(engine cranking). On Type 1 units, the preheat func

tion occurs w hen CR1 is energized and its norm ally-

open contacts are closed.

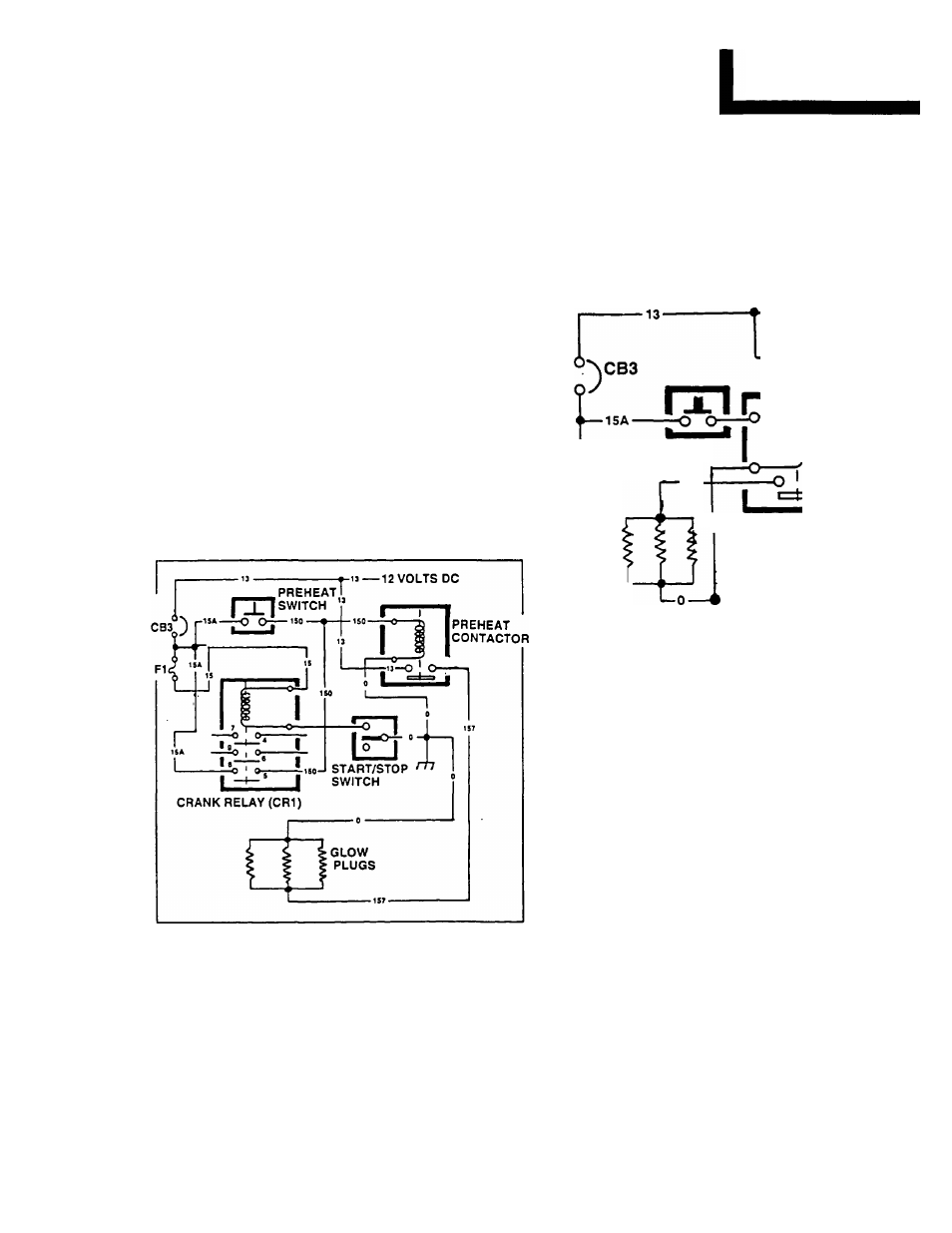

Figure 1. Preheat System - Type 1 DC Control

See Figure 1. Battery voltage Is available to the

preheat sw itch contacts. W hen the sw itch is closed,

battery voltage is delivered to the preheat contactor

coil. The coil energizes, the contacts close, and battery

voltage is delivered to the glow plugs.

During cranking (CR1 energized), 12 volts DC is

delivered across the closed CR1 contacts to the pre

heat contactor coil. Preheat occurs.

Units with Type 2 & 3 DC Control System

Rgure 2 is an operating diagram of a typical pre

heat circuit on units w ith Type 2 and 3 DC control

system . The preheat function w ill occur w hen the pre

heat contactor (PHC) is energized by actuating the

preheat sw itch to its closed position.

•13-12 VOLTS DC

13

PREHEAT

FI SWITCH

157

GLOWL

PLUGS

? PREHEAT

CONTACTOR

GROUND

Figure 2. Preheat System - Type 2 & 3 DC Control

Glow Plug Construction

See Figure 3. A thin, coiled HEAT W IRE is encased

in sintered m agnesium oxide pow der and enclosed by

a stainless steel SHEATH. One end of the w ire is

w elded to the SHEATH, the other end to the CENTER

ELECTRODE. W hen voltage is applied to the HEAT

W IRE, the w ire is heated.

1. Heat Wire

2. Sheath

3. Asbestos

4. Body

5. Nut

6. Magnesium Oxide Powder

7. Insulating Bushing

8. Center Electrode

(?)

(?)

T

©

Figure 3. Glow Plug Construction

PAGE 5.4-1