Generac Power Systems 53187 User Manual

Page 90

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

SECTION 3.2

WATER PUMP & THERMOSTAT

1

Water Pump (Continued)

REASSEMBLY (CONT’D):

4. Install a mechanical seal into the impeller by hand.

Apply 4 or 5 drops of silicon oil to the contact surface

of the mechanical seal.

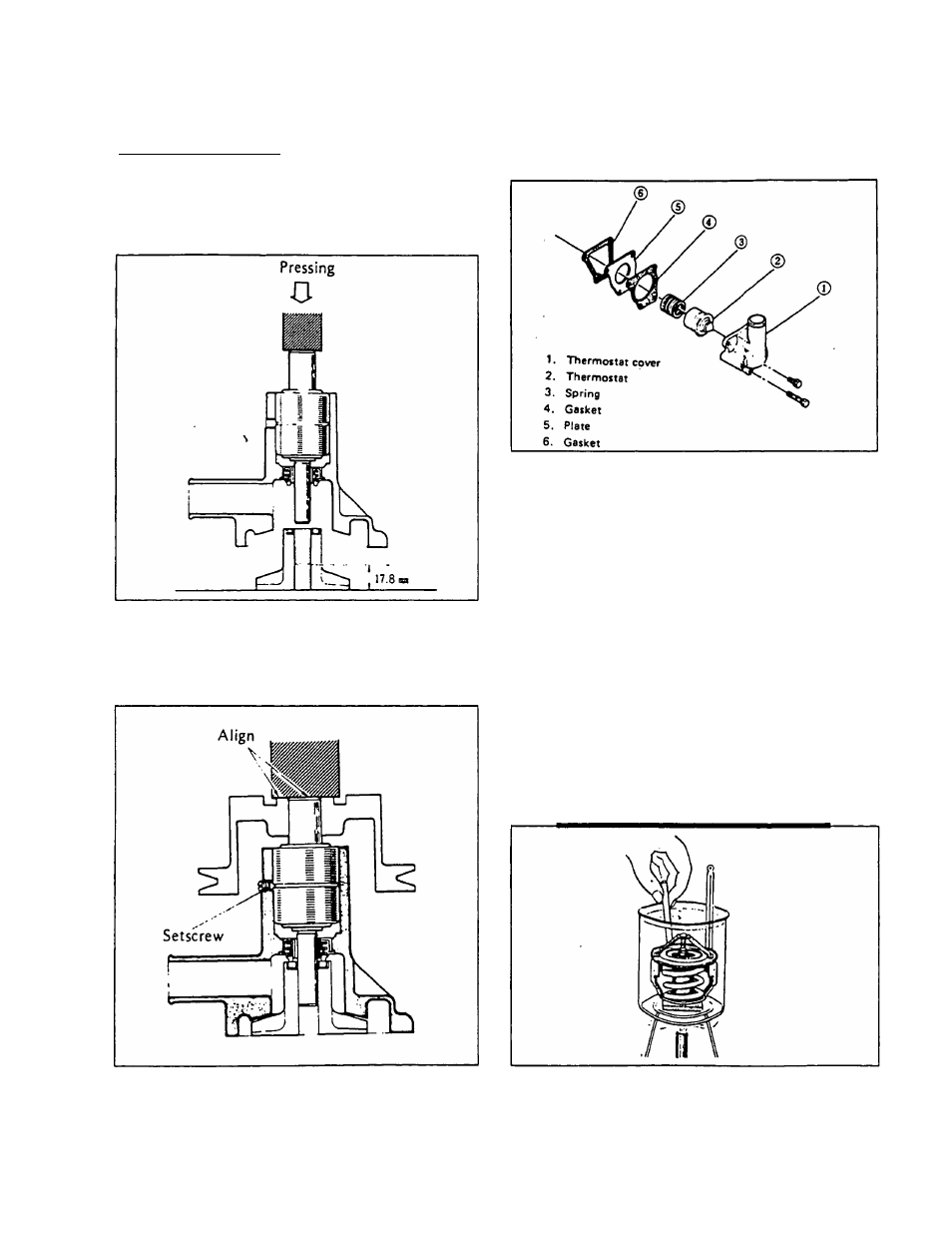

5. Press the impeller into the casing until the impeller

end is

O.70

inch (17.8mm) from the end of the bearing.

See Figure 5.

Figure 5. Press Im peller Into Casing

6. Use a SETSCREW to retain the bearing (Figure 6).

Then, press the fan pulley into place until the bearing

shaft end is aligned with the end face of the fan holder.

PART 3- LUBRICATION

AND COOLING SYSTEM

7.

Assemble the thermostat and spring to the water

pump casing. Install gaskets, plate and cover. Retain

with bolts.

Figure 7. Therm ostat Assem bly

8. Rotate the fan pulley to ensure there is no interfer

ence.

9. Adjust fan belt tension to obtain a 0.20 inch (5mm)

belt deflection when a 2.2 pound (1 kg) force is applied

to center of belt.

10. Test run the engine until hot toconfirm there are no

water leaks.

Thermostat

To test thermostat operation, immerse it in water. Raise

the

water

temperature

gradually.

Check

the

valve

opening temperatures and the valve lift.

NOTE: About 3 to 5 m inutes will be required before

the valve starts to operate.

Starts to Open:

Fully Open at:

Valve Lift at

Fully Open:

158’ F. (70‘ C.)

185* C. (85’ C.)

0.31 inch (8.0mm)

Figure 6. Fan Pulley & Setscrew Installation

Figure 8. Testing the Therm ostat

PAGE 3.2-2