Fuel nozzles and holders – Generac Power Systems 53187 User Manual

Page 104

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

PART 4

ENGINE FUEL SYSTEM

1

SECTION 4.5

FUEL NOZZLES AND HOLDERS

Section 4.5

FUEL NOZZLES AND HOLDERS

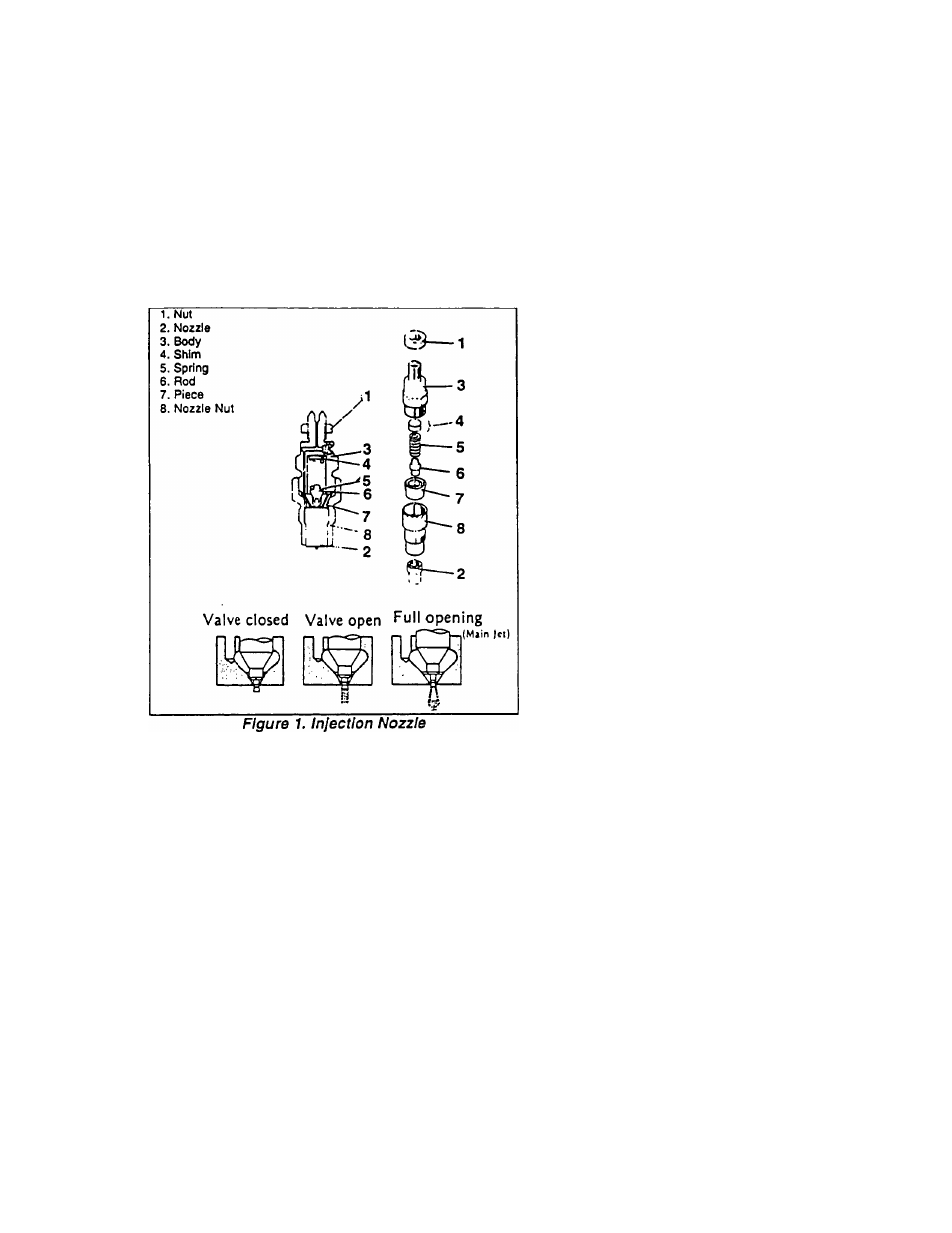

General

Fuel, supplied by the injector pump, is delivered to

the nozzle holder and to the nozzle body. When fuel

pressure is sufficient to compress the spring, fuel is

sprayed from the nozzle and into the combustion cham

ber.

Specifications

Needle Valve Diameter....................0.236 inch (6mm)

Pintle Diameter................................ 0.039 inch (1mm)

Valve Opening Pressure.................. 1636-1778 psi

Adjusting Pressure...........................1778-1849 psi

Spraying Angle................................ 12*

Check Injection Pressure

Use a nozzle tester to check injection pressure. Ad

just the pressure at which fuel injection occurs by

using shims, so that injection begins at 1707 psi (120

kg/cm^).

NOTE:

Injection

pressure

Increases

or

decreases

about 142.23 psi (10 kg/cnr) for a shim 0.1m m

(0.004 Inch) thick.

Using the nozzle tester, check the spray pattern as

follows:

□ There should be no fuel droplets in the spray.

□ The spray pattern should be a conical shape with

respect to the nozzle axis.

□ When sprayed at a distance of 11 -12 inches (30cm)

from a sheet of white paper, the spray pattern should

be a conical shape.

Use the nozzle tester to increase nozzle pressure to

1422 psi (100 kg/cm^). At that pressure there should

be no leakage from the bozzle tip.

PAGE 4.5-1