Generac Power Systems 53187 User Manual

Page 138

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

SECTION 5.9

TROUBLESHOOTING TEST PROCEDURES

Test 16- Check Wire 14 Voltage

PROCEDURE (CONT'D);

3. Crank the engine. The VOM connected in Step 2

should read battery voltage, indicating that the W ire 14

circuit is electrically hot

4. Repeat Step 3 w ith the m eter test leads connected

across circuit board term inals 10 and 2.

5. Repeat Step 3 w ith the m eter test leads connected

across circuit board term inals 11 and 2.

RESULTS;

1. If no voltage is indicated at W ire 14, rem ove and

replace the engine control circuit board.

2. If voltage tests are good, go to Test 17.

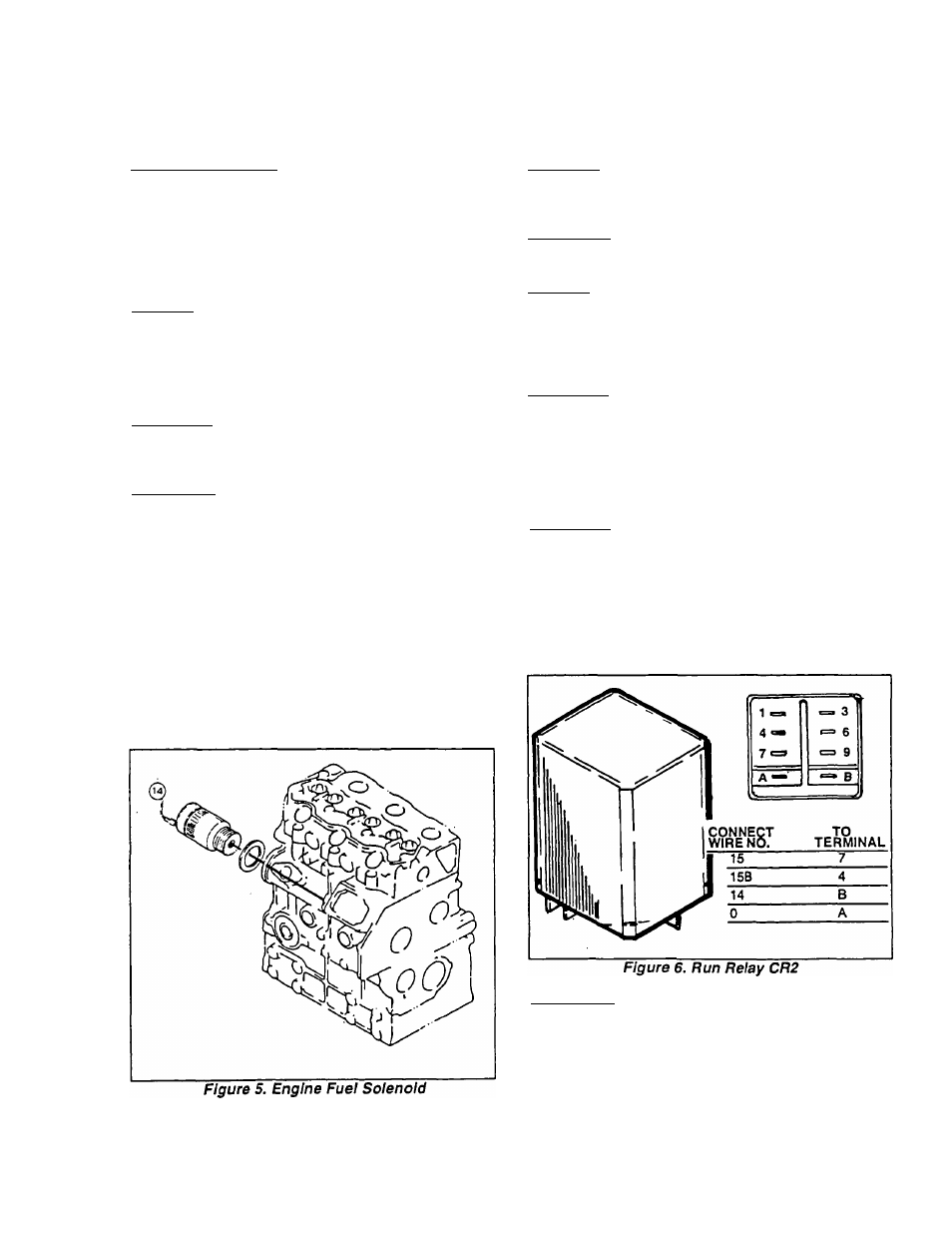

Test 17- Test Fuel Solenoid

DISCUSSION;

The fuel solenoid is a part of the fuel injection pum p

assem bly.

PROCEDURE;

1. Set a VOM to read DC volts.

2. Connect the m eter positive (+) test lead to the

term inal of the fuel solenoid; the com m on (-) test lead

to fram e ground.

3. Crank the engine. The m eter should read battery

voltage and the solenoid should actuate.

RESULTS;

1

PARTS

ENGINE ELECTRICAL SYSTEM

1. If the VOM reads battery voltage and the solenoid

actuates, go on to Test 18.

2. Replace the fuel solenoid if battery voltage is indi

cated but it does not actuate.

3. If battery voltage is not indicated, check W ire 14

betw een the fuel solenoid and the engine control board

for an open condition.

Test 18- Test Fuel Pump

Discussion;

The electric fuel pum p is turned on by W ire 14

during cranking and running operations.

PROCEDURE;

Refer to Part 4, Section 4.2,

FUEL PUM P.

RESULTS;

1. Replace fuel pum p if it is defective.

2. If fuel pum p checks good, go to Test 19.

Test 19- Check Engine Fuel & Mechani

cal Systems

DISCUSSION;

If the engine cranks norm ally but w ill not start, one

possible cause m ight be a m alfunctioning engine fuel

system or m echanical system .

Refer to Part 2, “Engine Mechanical System " and

Part 4, “Engine Fuel System “.

Test 20- Test Control Relay (CR2)

DISCUSSION;

Control relay (CR2) is used on Type 1 DC control

system s only. It acts as a “holding" relay. That is, w hile

cranking, relay (CR1) delivers 12 VDC to the engine

control circuit board. Circuit board action then delivers

12 VDC to the CR2 coil. CR2 energizes and its contacts/

close. W hen the start/stop sw itch is released to term i

nate cranking, 12 VDC is delivered to the engine control

circuit board via the closed contacts of relay CR2.

PROCEDURE:

In the control panel, locate the run relay CR2, to

w hich W ires 0, 14, 15 and 15B connect. Inspect all

w ires carefully. Com pare w iring connections to the

appropriate w iring diagram , m ake sure w ires are prop

erly connected.

PAGE 5.9-6