Parti the revolving field ac generator – Generac Power Systems 53187 User Manual

Page 12

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

SECTION 1.3- MAJOR COMPONENTS

(UNITS WITH 15 INCH STATOR)

1

AC Generator Disassembly

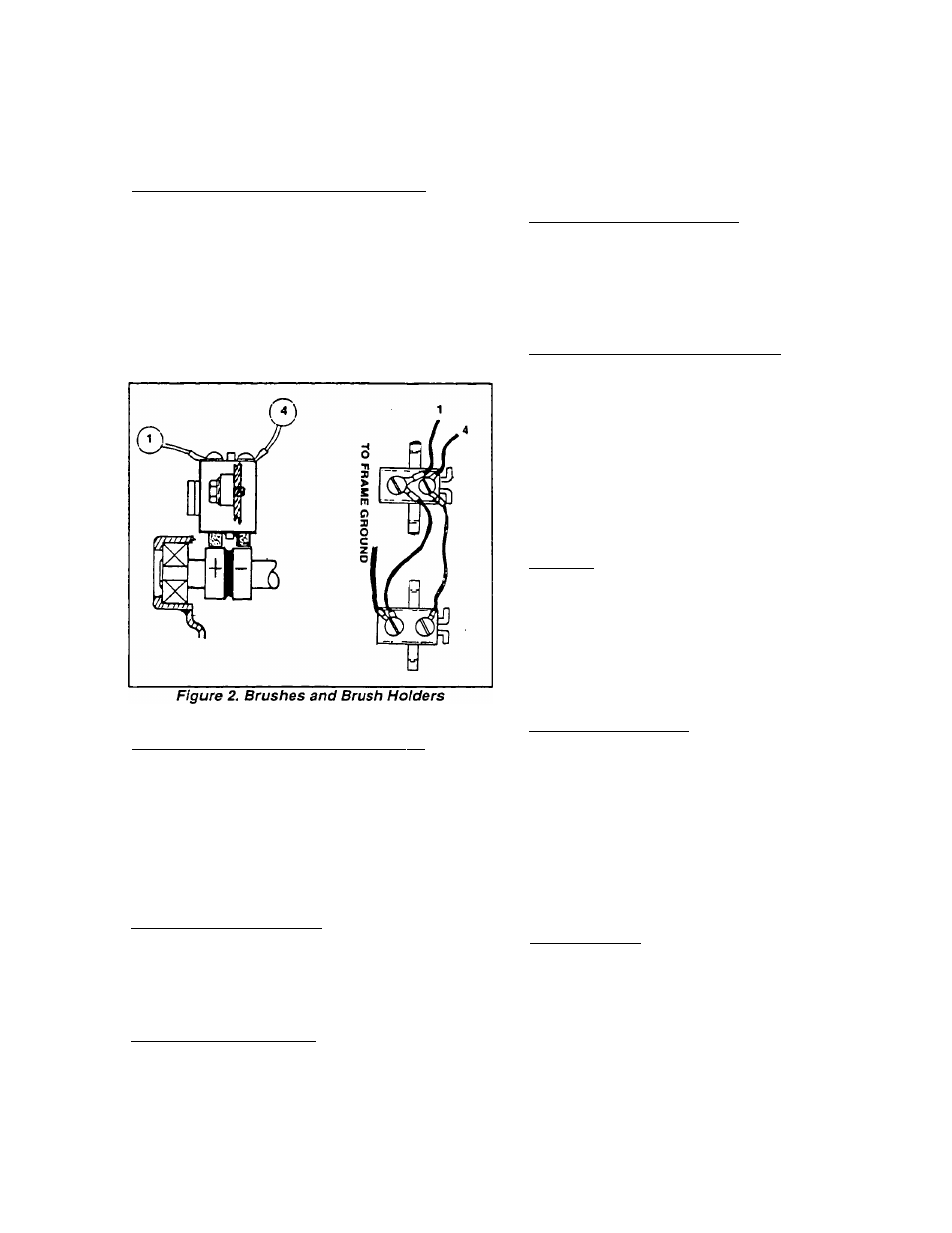

BRUSH ACCESS AND REMOVAL Figures 1 & 2);

See Rgure 1. Rem ove the TAPTITE SCREW S

(Item 2) that retain the tw o BRUSH COVERS (Item 33)

to the REAR BEARING CARRIER (Item 4). Rem ove

the BRUSH COVERS (Item 33) to gain access to the

BRUSH HOLDERS (Item 31).

See Figure 2, below . Rem ove W ires No. 1 and 4

from the BRUSHES in both BRUSH HOLDERS. Re

m ove the TAPTITE SCREW S that retain the BRUSH

HOLDERS to the REAR BEARING CARRIER. Re

m ove

both

BRUSH

HOLDERS,

along

w ith

the

BRUSHES

REAR BEARING CARRIER REMOVAL (Figure 1):

Rem ove HEX NUTS (Item 29), LOCKW ASHERS

(Item 27) and STUDS (Item 3) that retain the REAR

BEARING CARRIER (Item 4). To free the REAR

BEARING CARRIER (Item 4) from the ROTOR BEAR

ING (Item 5), use a soft m allet to tap around the outer

periphery of the BEARING CARRIER. Continue tap

ping until the BEARING CARRIER is free of the bear

ing.

STATOR REMOVAL (Figure 1):

The STATOR (Item 7) is "sandw iched" betw een the

ENGINE ADAPTER (Item 23) and the REAR BEARING

CARRIER (Item 4). Carefully rem ove the STATOR

(Item 7). DO NOT PERMIT THE STATOR TO DROP

OR BUMP THE ROTOR DURING REMOVAL.

ROTOR REMOVAL (Figure 1):

Rem ove the four FLANGED NUTS (Item 35) from

STUDS (Item 34). The ROTOR (Item 6), w ith FLEXI

BLE COUPLING (Item 13) attached, can now be pulled

free of the FLYW HEEL (Item 15).

PARTI

THE REVOLVING FIELD AC GENERATOR

To rem ove the FLEXIBLE COUPLING (Item 13)

from the ROTOR (Item 6), rem ove four HEX HEAD

FLANGED BOLTS (Item 10).

FLYW HEEL REMOVAL (Figure 1):

Rem ove

four

SCREW S

(Item

11)

and

LOCKW ASHERS

(Item

12).

Then,

rem ove

FLY

W HEEL (Item 15). If desired, the FAN RING (Item 14)

can

be

rem oved

by

rem oving

HEX

HEAD

CAPSCREW S (Item 8) and LOCKW ASHERS (Item 9).

ENGINE ADAPTER REMOVAL (Figure 1);

To rem ove AIR RING BAFFLE (Item 17), rem ove

CAPSCREW S (Item 8) that retain

It

to the ENGINE

ADAPTER (Item 23).

Support the engine and rem ove all fasteners that

retain the ENGINE ADAPTER to the BASE ASSEM

BLY. Rem ove HEX HEAD CAPSCREW S (Item 40) and

LOCKW ASHERS (Item 27). Finally, rem ove the EN

GINE ADAPTER.

Components Inspection and Testing

GENERAL;

Follow ing disassem bly, generator com ponents

should be cleaned, dryed and inspected or tested.

Never reassem ble a generator having defective parts.'

Keep m ajor parts separated and keep the m ounting

hardw are along w ith the parts they are used w ith. Store

parts in a clean, dry area w here condensation, dirt, or

m oisture w ill not dam age them .

REAR BEARING CARRIER:

The Rear Bearing Carrier (Figure 1, Item 4) is an

alum inum casting. Clean the casting and blow dry w ith

air. Inspect carefully for cracks, obvious dam age. An

insert has been pressed into the Carrier center bore, to

accom m odate the Rotor Bearing. Replace the Rear

Bearing Carrier if the center bore diam eter is not w ithin

the follow ing dim ensions:

BEARING CARRIER CENTER BORE

2.9527-2.9533 Inches (74.999-75.014m m )

ROTOR BEARING:

The rotor bearing is a prelubricated and sealed ball

bearino that requires no additional lubrication for the

life of the bearing. Spin the Rotor bearing by hand and

check it for binding, seizing, roughness, etc. If the

bearing is defective, it m ust be replaced.

The bearing m ay be rem oved from the Rotor shaft

using a bearing puller. A new bearing can then be

pressed onto the shaft. Exert pressing force on the

bearing inner race only- NEVER on the bearing outer/'"~^^

race.

PAGE 1.3-2