Generac Power Systems 53187 User Manual

Page 78

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

PART 2

ENGINE MECHANICAL

Crankshaft (Continued)

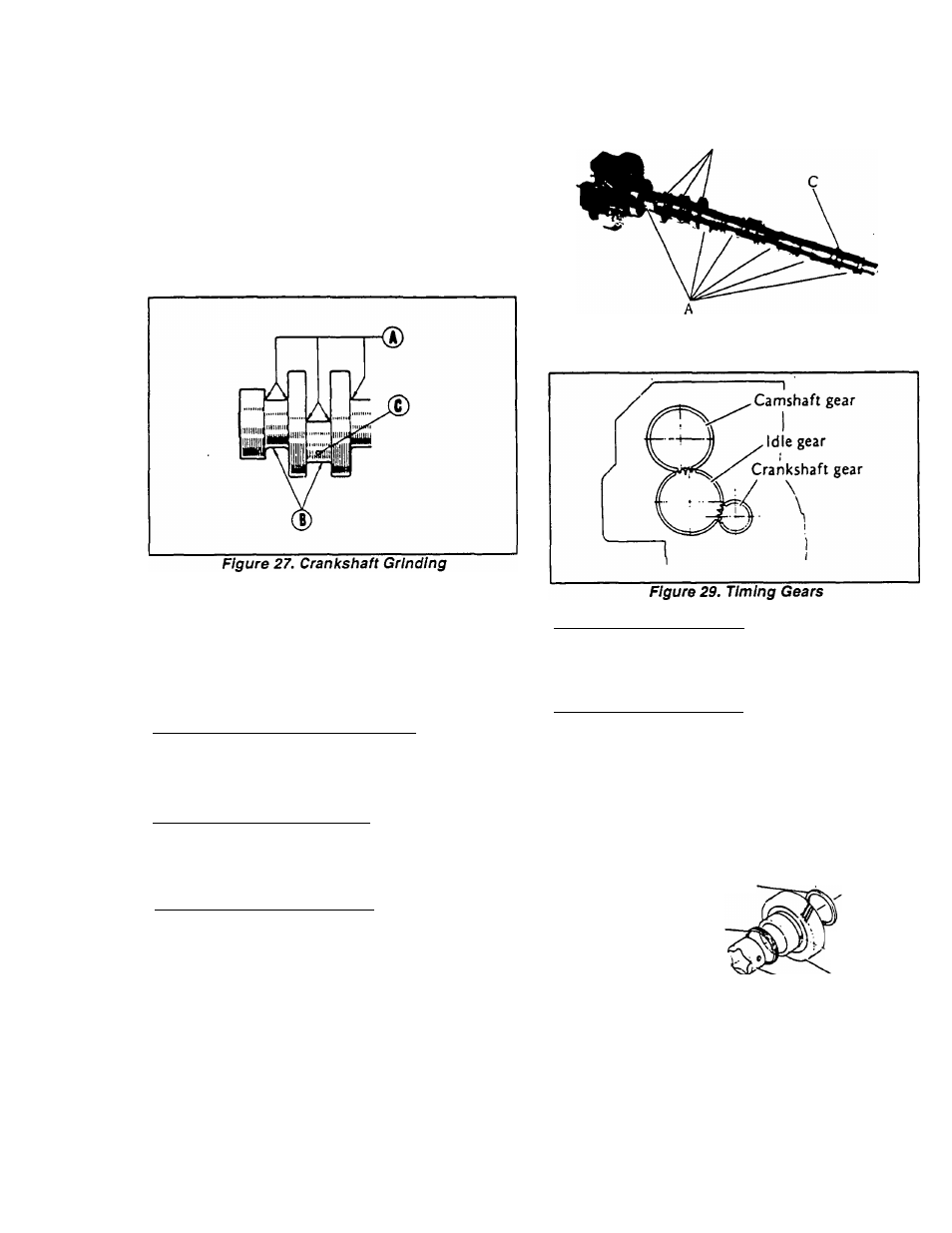

3. W hen grinding the crankshaft, the foiiow ing specifi

cations appiy (Figure 27);

A

Radius at PInAJoumal ■ 0.11B

*

0.004 In. (3tnm-M).1mm)

В

Finish precision 1.62

(VW )

C

Radius around oil hole & 0.079 In. (2mm) шах., 0.020 In.

(0.5mm) mln.

NO TE: Use No. 400 sandpaper for final polishing.

Camshaft Assembly

Inspect the journals and cam s for w ear and dam

age. If allow able lim its are exceeded, replace the cam

shaft.

See Figure 28. Cam height tolerances are as fol

low s;

A

INTAKE/EXHAUST VALVE CAM HEIGHT;

Standard

Value:

1.0413-1.0433

inch

(26.45-

26.50m m )

Allow able Lim it: 1.0275 inch (26.1m m )

B

INJECTION PUM P CAM HEIGHT;

Standard

Value:

0.9425-0.9472

Inch

(23.94-

24.06m m )

Allow able Lim it: 0.9370 inch (23.8m m )

C

FUEL FEED PUM P CAM HEIGHT;

Standard Value: 1.0590-1.0630 inch (26.9-27.0m m )

Allow able Lim it: 1.0236 Inch (26.0m m )

Timing Gear

Inspect tim ing gears for w ear or dam age at their engag

ing areas. Replace if dam aged or w orn excessively.

Use a thickness gauge or a dial indicator to m easure

gear backlash. If allow able lim its are exceeded, replace

the tim ing gears as a set.

1

SECTION 2.4

DISASSEMBLY AND INSPECTION

Figure 28. Cam shaft Assem bly

BACKLASH OF TIMING GEARS:

Standard Backlash: 0.003 inch (0.08m m )

Allow able Lim it: 0.010 Inch (0.25m m )

Oil Pump

REMOVAL AND DISASSEMBLY;

1. See Figure 30. Rem ove the SNAP RING.

2. Rem ove COLLAR, SPRING and SHIM .

3. Rem ove IDLE GEAR, VANE and OIL PUM P COVER

as a unit.

4. Rerm ove ROTOR and THRUST W ASHER.

5. Rem ove OIL PUMP COVER from the IDLE GEAR.

6. Rem ove SPRING from the IDLE GEAR. Rem ove the

KNOCK PIN.

7. Rem ove the VANE from the IDLE GEAR.

Thrust w asher

Spring

Rotor r

Shim '

’ vine Idle gear

Collar

• Oil pum p cover

-Spring

Knock

■ I

pin

Snap ring

Figure 30. Oil Pump Assembly

PAGE 2.4-9