Generac Power Systems 53187 User Manual

Page 79

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

SECTION 2.4

DISASSEMBLY AND INSPECTION

1

Oil Pump (Continued)

INSPECTION AND REASSEM BLY:

1.

Inspect the OIL PUMP COVER, ROTOR and VANE

for w ear. Replace if w orn or dam aged.

2. Check the clearance be

tw een

the

ROTOR

and

VANE. If clearance Is exces

sive, replace parts.

3. Reassem ble the oil pum p in the reverse order of

disassem bly.

a. W hen reassem bling, align the set m arks on the

crankshaft gear and the idle gear.

b. Adjust the side clearance betw een the rotor and vane

to 0.0039-0.0059 inch (0.1-0.15m m ).

PART 2

ENGINE MECHANICAL

Water Pump & Thermostat

Refer to Part 3,

•ENGINE LUBRICAT ION AND

CO OLING SYST EM ".

Fuel Filter & Feed Pump

See Part 4 of this m anual,

’ENGINE FUEL SYS

TEM ’.

Governor & Injection Pump

See Part 4,

’ENGINE FUEL SYST EhT .

Nozzles and Holders

See Part 4,

’ENGINE FUEL SYST EM ".

Oil Filter

CONSTRUCTION AND FUNCTION:

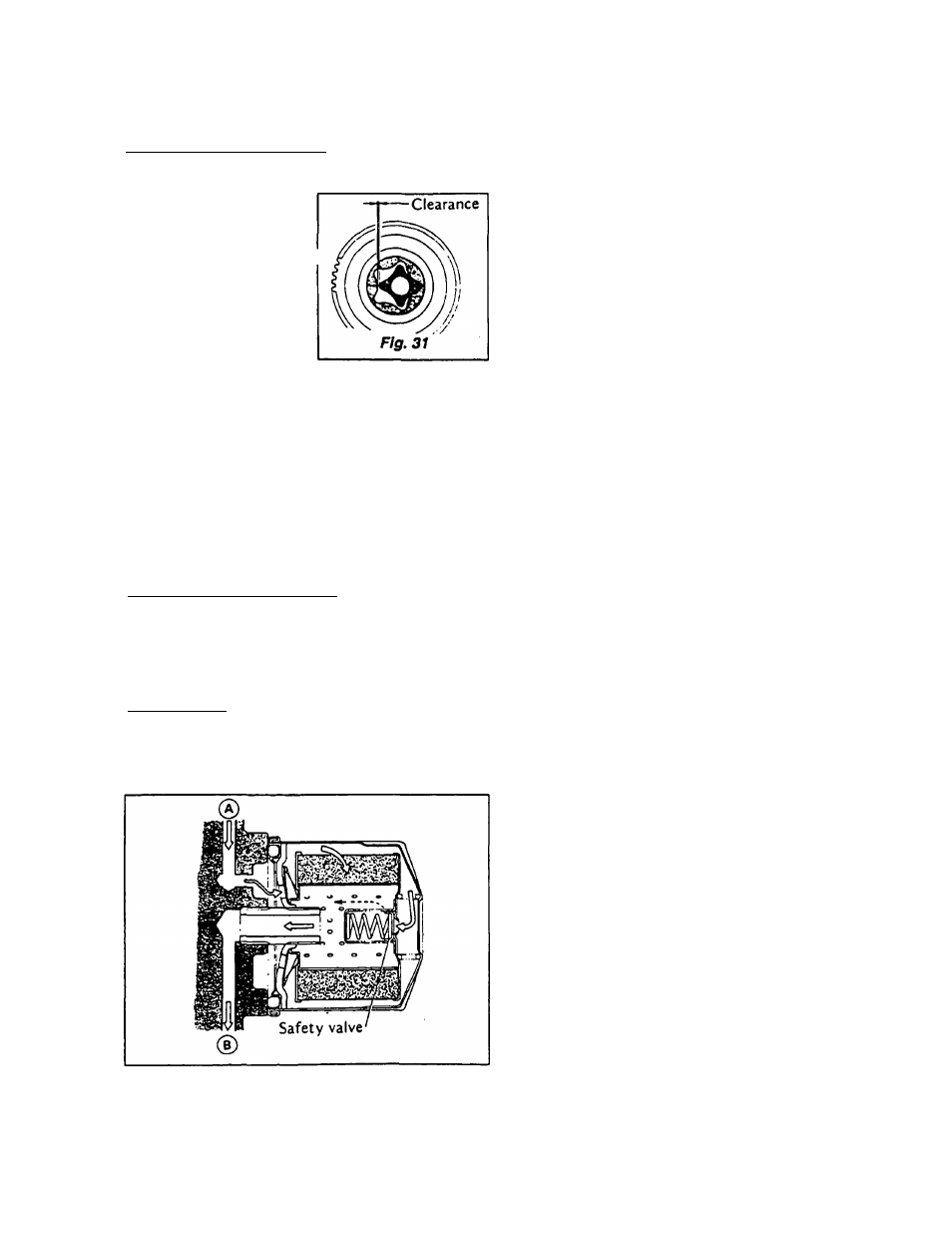

The oil filter is a cartridge type. A SAFETY VALVE

w ill open to bypass oil around the filter if the filter should

becom e clogged. See Figure 32. Pressure oil from the

oil pum p enters at “A". The oil is filtered and then exits

the filter at “B".

REPLACEMENT;

Replace the oil filter every 200 hours of operation.

Prior to installing a new filter, coat its m ounting face w ith

clean oil. Tighten the filter w ith the hand only. Do not

reuse the rem oved filter.

Figure 32. Oil Filter

PAGE 2.4-10