Part 2 engine mechanical – Generac Power Systems 53187 User Manual

Page 72

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

PART 2

ENGINE MECHANICAL

I

SECTION 2.4

DISASSEMBLY AND INSPECTION

VALVE SEAT (CONTO):

Cylinder Head Assembly (Continued)

Valve seat contact width

Standard width

1.2 to 1.5 mm

Allowable limit

2.0 mm

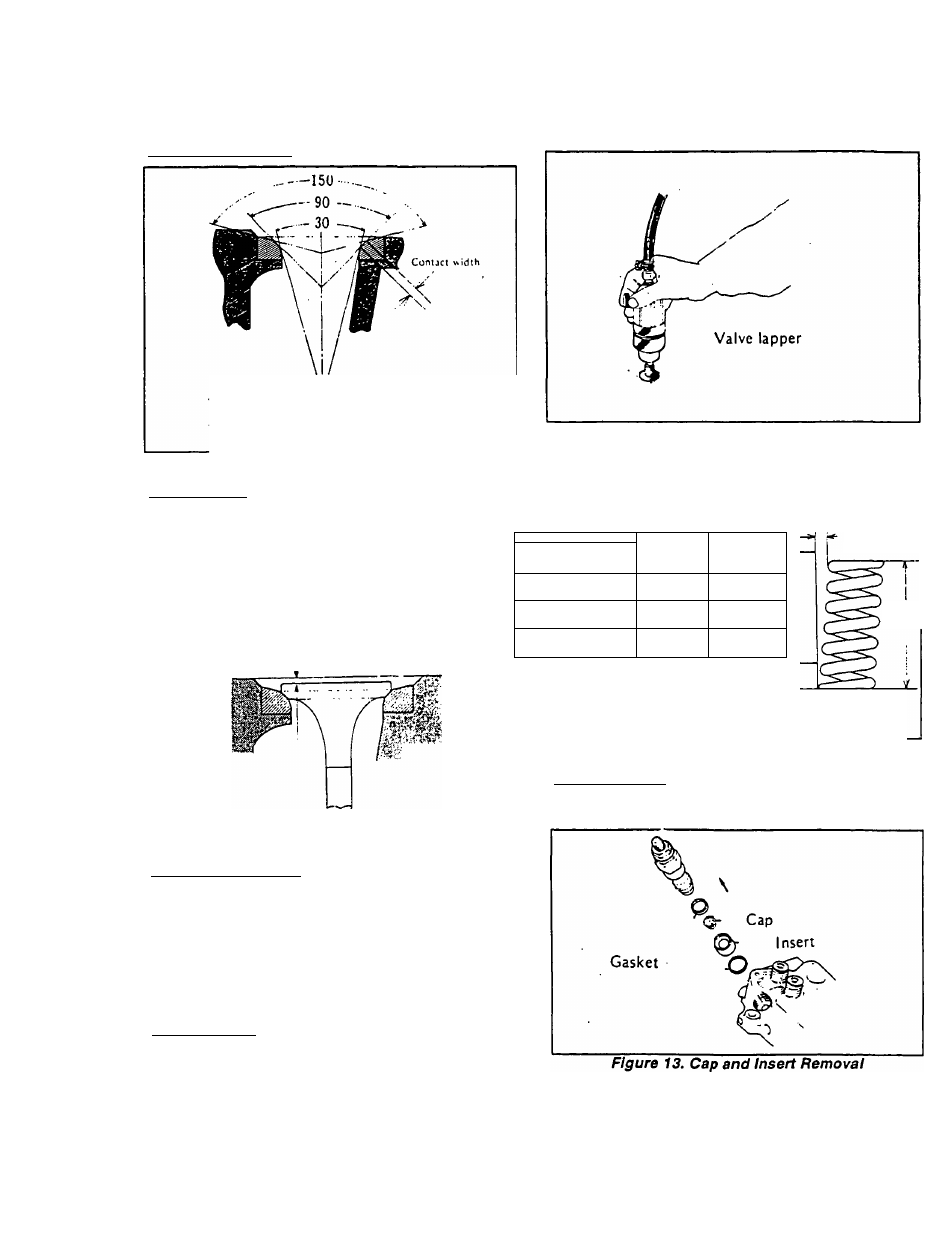

Figure 11. Grinding the Valve Seat

Figure 9. Correcting the Valve Seat

VALVE RECESS:

If the valve recess (Figure 10) exceeds allow able

lim its, replace the valve seat.

Recess of Valve Seat

Standard Recess

0.033-0.045 inch

(0.85-1.15mm)

Allowable Limit

0.071 inch (1.8mm)

Recess

Standard

value

Allowable

limit

Squareness (mm)

1.2

2.0

Free length (mm)

35

33.5

Spring

force

130.4mm

at compressioned) (kg)

8.1

7

Squareness

Free len

Figure 12. Valve Springs Inspection

CAP AND INSERT:

Rem ove CAP and INSERT from the cylinder. In

spect and clean the com bustion cham ber.

Figure 10. Checking Recess of Valve Seat

GRINDING VALVE SEAT;

See Figure 11. Use a valve seat grinder and valve

grinding com pound to grind valve seats. Check the

valve contact face for correct contact and positioning.

NO TE: W hen Installing a new cylinder head, use the

valve seat cutter to obtain correct seat contact w ith

recess of seat. T hen, use lapping com pound to lap

the valve In.

VALVE SPRINGS:

Inspect valve springs for dam age. Check spring

squareness. Use a spring force tester to test for cor-

rectspring force and free length.

PAGE 2.4-3