Top Flite TOPA0130 User Manual

Page 45

HINGE THE ELEVATOR

❏ ❏

2. Test fit the elevators to the stabilizer

with all of the hinges and the wire joiner in

place. Make sure the elevators are both set at

the same angle. Make adjustments if necessary.

❏ ❏

3. Work a generous amount of 30-minute

epoxy into the wire joiner holes in the elevators.

❏ ❏

4. Work the elevator hinges into the stab

and, as you do this, insert the wire joiner all the

way. Wipe away any excess epoxy. Glue the

hinges in place using 4-6 drops of thin CA on

both sides of each hinge.

HINGE THE AILERONS AND

RUDDER

❏

5. Pack 30 minute epoxy into the tail wheel

hole in the rudder, then install the Rudder in the

same manner as the Elevators.

❏ ❏

6. Hinge the Ailerons using the same

technique as the Elevators.

❏ ❏

7. Flap hinge installation is covered in the

Flap Fitting section on page 41.

THERE SHOULD BE NO HINGE GAP

FINAL CONTROL HARDWARE

HOOKUP

❏ ❏

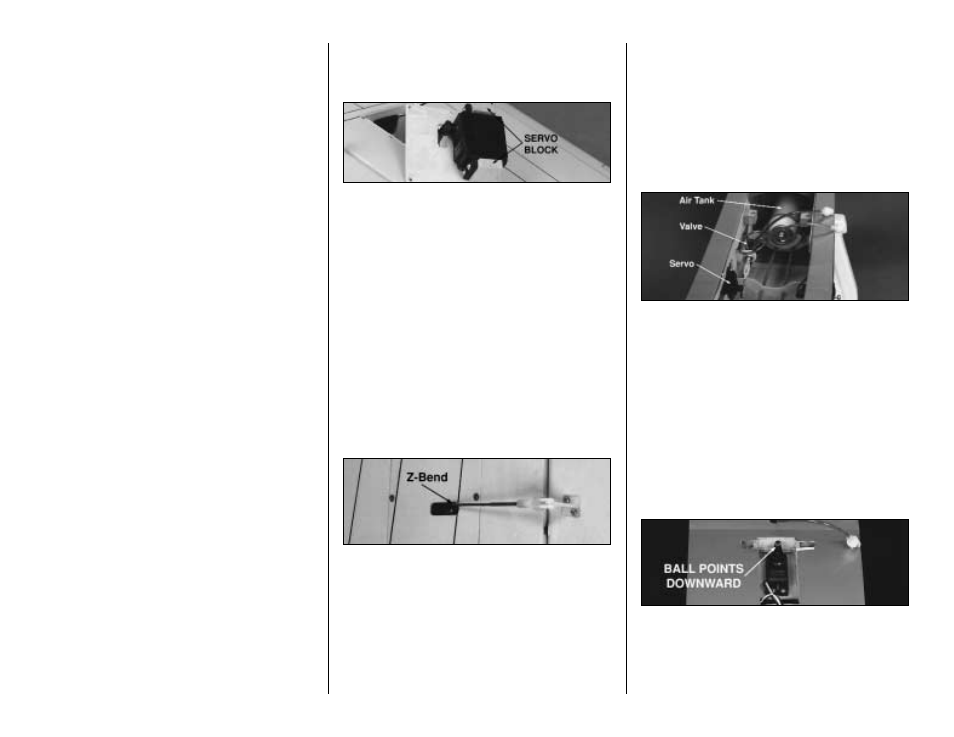

1. Epoxy the 5/16" x 3/4" x 7/8" hardwood

Flap Servo Mounting Blocks to the die-cut

1/16" ply Flap Servo Hatches. Install the flap

servos as shown in the photo and on the plans.

Fish the servo wires through to the opening at

the center of the wing, then plug them into a "Y"

cord. Before permanently screwing the servo

hatches in position, hook up your radio and set

the flap servos' throws.

❏ ❏

2. Install the flap and aileron horns in line

with the pushrod exits as shown on the plans.

Drill 1/16" holes into the control surfaces at the

proper horn locations, then soak the holes with

CA glue. Screw the horns in place with #2 x 3/8"

Sheet Metal Screws.

❏ ❏

3. Hook up and adjust the aileron and

flap linkages. Two .074 x 4" Threaded End

Rods and Nylon Clevises are supplied to

make the flap pushrods. The flap pushrods

may be connected to the ser vos using Z-

bends, or solder-on clevises (not included.)

Refer to the Control Surface Throws section

for movement recommendations.

❏

4. The Rudder is connected using a Small

Control Horn (cut down to two holes) and a

Nylon Clevis. Refer to the plans for the proper

location. Mark the location of the horn and drill

two 1/16" pilot holes par t way through the

rudder. Thoroughly soak the holes with CA. Put

a drop of CA on the back of the horn and screw

the horn onto the rudder with two #2 x 3/8"

Sheet Metal Screws.

❏

5. The retract air valve, tank, and servo

installation can be seen in the photos above and

below.

We found that a micro (Futaba #133)

servo worked well for actuating the air valve.

The tank fits in the built-in cradle in formers F-5

and F-6. It can be secured with two #2 x 3/8"

screws and a rubber band (not supplied) or

silicone glue.

❏ ❏

6. Solder-on threaded couplers and nylon

clevises are recommended for internal elevator

and rudder servo hookups. Refer to the photos

and plans for proper servo and horn orientation.

❏

7. The aileron servo hookup can be seen in

the above photo. The aileron servo is fitted with a

2-56 Threaded Ball Link connector that points

downward toward the dual aileron connector.

45