Top Flite TOPA0130 User Manual

Page 38

❏

4. Position the die-cut 3/32" Wing Fillet

Formers at the locations shown (dotted line) on

the plans. There are three formers per side.

Glue the formers in place. Sand them flush.

❏

5. Cut two 13-1/2" long Fillet Skins from

1/16" x 3" x 30" balsa sheet. Taper one long

edge to blend with the Fuse. Hold the skin

against the Fillet Formers, even with the fillet

reference line, then trace the outline of the

saddle on the inside surface. Cut away the

excess when marked.

❏

6. Glue the Fillet Skins in position. Lightly

sand the top edge with a sanding block. Apply a

thin layer of Balsa Filler along the

long edge

and also at the forward end to start building up

the LE contour.

❏

7. Use the templates provided on the plans to

cut two sets of Rear Fillet parts from 1/16"

balsa. Taper (to a sharp edge) the edges of each

part that will contact the fuse sheeting. Glue the

parts to the fuse in the order shown in the photo.

Test fit each piece as you proceed, then use

medium CA along the edges. Lightly sand the

joints, then apply a thin layer of balsa filler to

blend and contour the edges with the fuse.

❏

8. When the filler is dry, sand and blend the

fillet with the fuse. Add extra filler as needed to

obtain smooth curves.

With regards to building, you are on the home

stretch. Get a good night's sleep, then play

hooky from work to do the final assembly steps.

INSTALL THE ENGINE

You have a variety of options when it comes to

engine selection. Our original prototype weighed

8.75 lbs and flew extremely well with an O. S.

.61SF 2-stroke for power. We have also

successfully flight tested the model with an O.S.

1.20 Surpass 4-stroke engine. Due to the high

lift design of the wing, the Texan will have a

tendency to climb as full power is applied when

using a 1.20 4-stroke engine. This condition can

be controlled by adding an additional one

degree of down thrust to the engine.

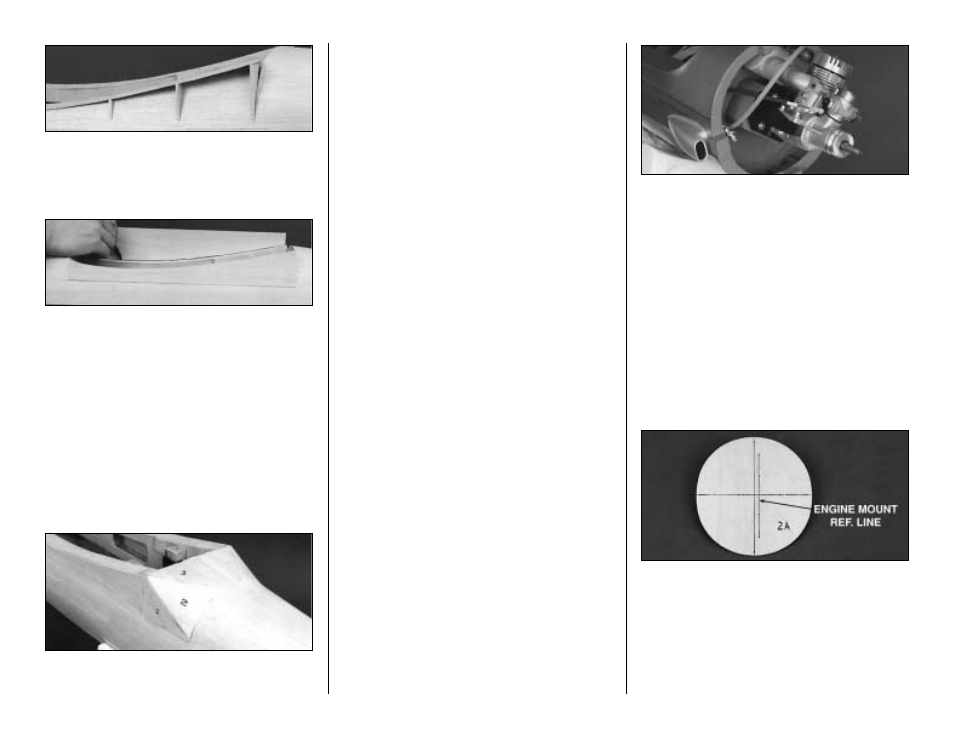

NOTE: The following sequence

shows the installation of an O. S. .91

Surpass 4 stroke engine. We mounted

all test engines at a 45 degree angle

towards the bottom of the fuse. This

orientation allows the exhaust port of a

2-stroke engine to be connected to a

Top Flite In-Cowl Muffler and to exit

the cowl via the

"scale" exhaust stack.

If you plan on using the Top Flite In-Cowl

Muffler, you will have to do a little sanding on

F-1 to provide clearance for the muffler and to

permit access to the mounting screws. To

strengthen the sheeting in the area that the

muffler (and scale exhaust stack) will exit the

fuse, add some scrap 3/32" balsa between the

stringers, from the firewall to F-1.

❏

1. Draw reference lines through the dots that

are stamped into the die-cut 1/8" Birch ply F-2A

Firewall. The short offset line is to be used for

the centerline of the engine and will allow the

prop to be centered in the cowl opening.

Remember, the Firewall already has been built

with 2 degrees of right thrust.

38