Top Flite TOPA0130 User Manual

Page 24

❏ ❏

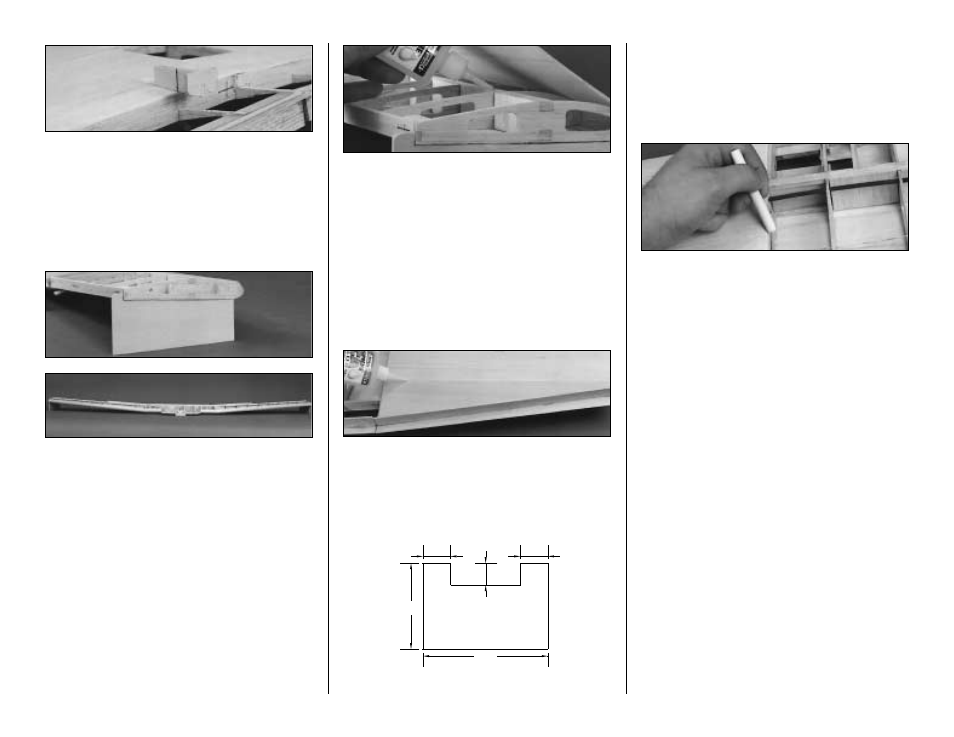

4. Use the reference line you drew to

align the TE Jig with the TE at Flap Center. Tack

glue the TE Jigs to the bottom skin under the W-4

Ribs. If you are not using flaps, and the TE has

been sheeted, you can find the location of W-4

by using a pin or a sharpened wire to poke a

small hole through the skin from the top at

the correct spot.

❏ ❏

5. Place a die-cut 1/8" plywood Tip Jig

under each W-15 rib. You should tape or tack

glue the Jig to the wing.

❏ ❏

6. Check the fit of an outboard skin to the

wing structure. Make adjustments if required to

fit flush with the LE. Sand a slight bevel to the

edge of the skin that will contact the LE to allow

for a better gluing surface. Once a good fit is

obtained, mark and cut the inboard edge of the

skin so that it will fall on the joint between

W-5 and W-6.

❏ ❏

7. Hold the skin in place, butted firmly

against the LE, then wick Thin CA into the joint.

Wipe off any excess glue before it dries.

❏ ❏

8. Gently lift the skin and apply a bead of

Thick CA (CA-) to each rib. Apply glue to the

Main Spar and the TE at the Flaps and Aileron

last. Roll the skin into position and smooth it into

contact with the underlying structure. Add

weights to the entire top of the wing while the

glue dries. A small stack of magazines are ideal

for this purpose as they will match the contour of

the wing.

9. Repeat steps 6,7, and 8 for the other panel.

❏

10. Measure and cut a 1/16" balsa sheet to

fit the openings at the aft end of the wing skins.

When satisfied with the fit, glue them in place.

❏

11. Cut the top center panel skin to the

dimensions shown in the sketch. When cut,

t h e s k i n w i l l b e s l i g h t ly l a rg e r t h a n t h e

opening to allow for the edges to be trimmed

to the exact size.

❏

12. Lightly rub some chalk along the top

edge of the outboard panel skin. Tape the aft

edge of the center skin in position along the ply

(or tapered balsa) TE. By pressing the center

skin down over the chalked edges, and rubbing

your finger over the seam, you will transfer an

exact outline in chalk to the center skin. Trim

away the excess balsa with a hobby knife, then

sand with 220 grit for a precise fit. Fit the LE of

the sheet by trimming a little at a time. Do not

glue it in place yet. Tape the center skin in

position for the time being.

❏

13. Remove the excess plastic from around

the perimeter of the Wing Center Fairing. (See

photo at step 16) Score the plastic with a hobby

knife then flex the plastic until it breaks off. Trim

the Fairing to the embossed outline that can be

found on the inside of the part. Try to make nice

straight edges as you will cut the balsa skin to

match the Fairing.

❏

14. Drill two 5/16" holes in the Fairing to allow

the wing dowels to poke through. The Center

Fairing has been marked with the proper location

for the holes, but building variations may require

that you enlarge the holes for a good fit.

3-3/4"

3-3/4"

3"

17"

11-3/4"

24