Top Flite TOPA0130 User Manual

Page 34

❏ ❏

14. Once the epoxy has cured, apply

more masking tape about 1/4" out from the joint,

then use model filler to create a neat fillet along

the length of the joint. Once again, remove the

tape before the filler dries and feather the edges

with your finger to avoid excessive sanding.

This

is also a good time to fill in the opening around

the rudder pushrod tube with filler.

❏

15. Repeat steps 13 and 14 for the top of

the Stab.

❏

16. Note: Protect the stab and fin skins

with masking tape around where you will be

sanding to avoid the possibility of

dangerously thinning the skins. Lightly sand

the first layer of filler around the Stab and the

Top Deck, then apply a second coat. This time

start building it up around the LE of the fin so

that the fin will blend smoothly with the Fuse.

When the filler is dry use different thickness

dowels wrapped with 220 grit sandpaper to

shape the fillet.

Take your time to blend all

contours with the Fuse.

This will finish the top half of the fuse, except for

final sanding and covering. Take a breather to

admire you work, then turn the assembly over

and add glue fillets to the inside, wherever you

see a need. You might even want to take a

minute to trim the canopy to size and check the

fit. Looking good!

FRAME THE FUSE BOTTOM

From here on you will need a cradle to support

the Fuse. As mentioned earlier, you can use a

ready-made stand or a Styrofoam ice chest can

be shaped to do the job.

❏

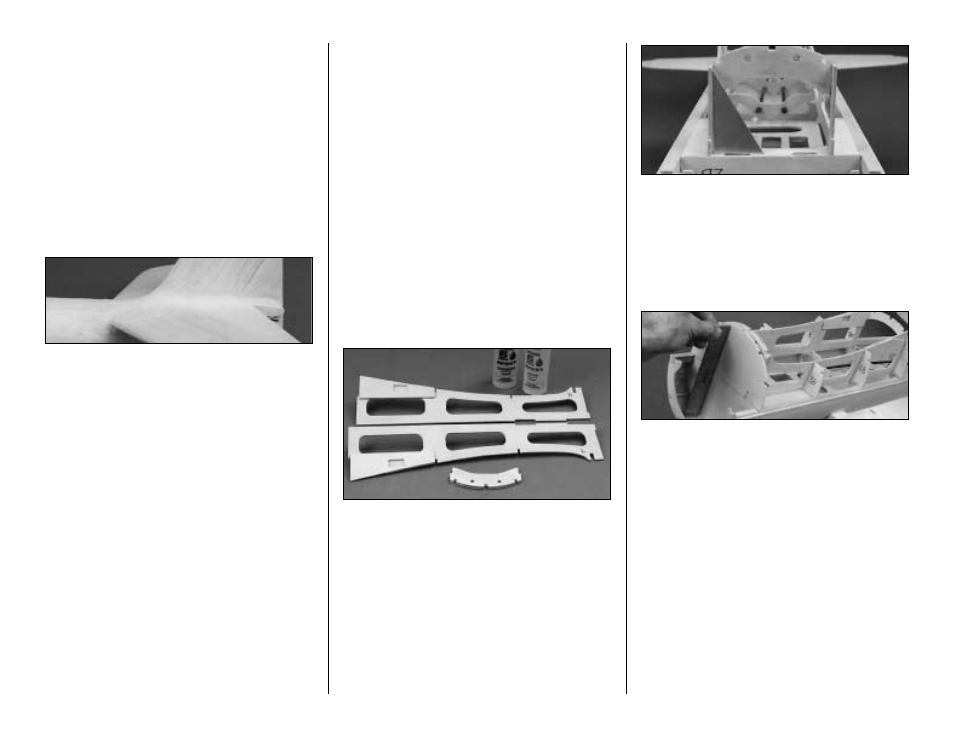

1. Locate the right and left die-cut 1/8" ply

Wing Saddles. If you hold them together you

will notice that one is longer than the other.

The

longer one fits the left side of the fuse

(or to your right when the fuse is upside down).

Check the fit of both parts with the notches in

the forward crutch, then mark the insides of

both parts.

❏

2. Use 6-minute epoxy to glue the die-cut

1/8" ply Wing Block Doublers to the inside

surface of the Wing Saddles. Be sure that the

aft edge is flush with the notched portion of the

saddle and that the bottom edge is flush with

the bottom of the saddle as shown in the photo.

❏

3. Use 6-minute epoxy to glue the two die-cut

1/8" ply Wing Dowel Formers together.

❏

4. Test the Wing Saddles with the forward

Crutch. Test fit the Wing Dowel Former with the

Wing Saddle. When satisfied with the fit, glue all

components together with medium CA. Apply a

fillet of CA along the joint between the Wing

Dowel Former and the Saddle. Note: Use a

triangle to square up the Saddles with the Fuse.

❏

5. Glue the die-cut 1/8" ply F-2C, F-3B, F-

4B, and F-5B to the Wing Saddle and top

Formers as shown in the photo. Make sure that

the die stamped numbers face forward and that

all parts fit their respective notches. Check that

F-2C is even with F-2B by holding a shor t

straightedge across the joint.

❏

6. Glue F-6B, F-7B, and F-8B in position as

shown on the plans. Use a straightedge to

maintain vertical alignment between top and

bottom Formers. Hint:

For better bonding with

the sheeting, lightly sand the formers' edges so

that they are slightly beveled to match the angle

of the fuse.

34