Top Flite TOPA0130 User Manual

Page 15

❏ ❏

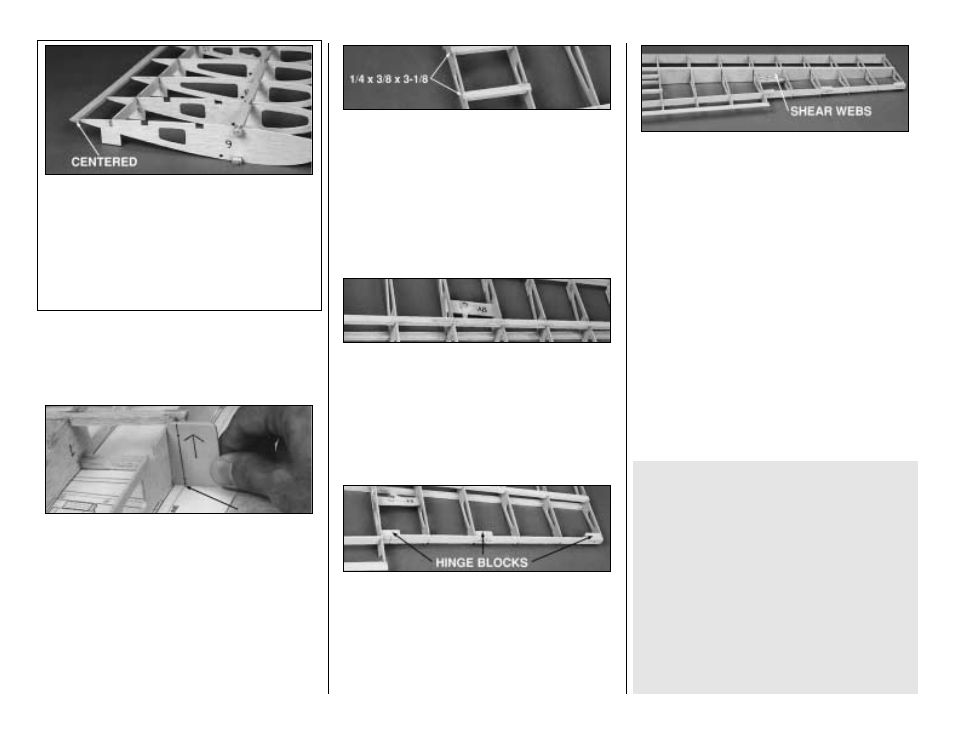

9. Glue the Flap TE to ribs W-7 through

W-10. The Flap TE should be centered on the

aft edges of the ribs and should be (as shown in

the cross-section on the plans) aligned with the

top and bottom of the ribs. Make sure all the jig

tabs are contacting the table. A metal

straightedge can be placed on the structure over

the jig tabs to hold them down evenly.

Now you'll see why we didn't want you to glue

W-6 in place earlier.

❏ ❏

10. Draw a line through the two punch

marks on the ply Dihedral Gauge. With the

arrow on the gauge pointing up, position the

gauge on the plan so the line you drew is on the

dashed reference line printed on the plan.

Move the gauge along the reference line and

adjust the angle of W-6 until it's flush with the

gauge from the LE to the TE. After double (

even

triple) checking that the angle is perfect, glue

W-6 in place at all points of contact.

❏ ❏

11. Cut the two balsa 1/4" x 3/8" spar cut-

offs to 3-1/8" long. Glue two of these sticks into

the notches in ribs W-6 and W-7. These will act as

supports for the flap servo hatch. If you don't plan

on using flaps, fill the notches with scrap balsa (or

install the rails even if you won't use them).

❏ ❏

12. Glue the Aileron Bellcrank assembly

into the slots in ribs W-10 and W-11. The

bellcrank should face away from the building

board as shown in the photo.

❏ ❏

13. Locate the 3/8" x 1/2" x 15" balsa

Flap & Aileron Hinge Block. Cut six 1" lengths

to use as aileron hinge blocks (save the balance

for use as flap hinge blocks). Glue 3 blocks

where shown on the plans; save the other 3 for

use on the second wing panel.

❏ ❏

14. Trim the 1/16" x 2-3/4 x 1-11/16"

balsa Shear Webs to fit behind the spar

between ribs W-7 through W-15. Do not install

a shear web between W-6 and W-7. Glue them

in place with CA+. Wick CA between all the

joints of the shear webs and the spars to make

sure they are well bonded. It's not important to

glue the shear webs to the ribs.

If you are building your wing without operational

flaps you can take a short break to admire your

handiwor k. When fully revived, clean the

sawdust off your bench, swap the plan sheets,

and get busy building the other outer wing

frame. On the other hand, if you are installing

operational flaps, you still have some more work

to do, so get back to it. You can rest later.

PREPARE THE WING PANELS FOR

THE FLAPS

Do the following steps if you are building

operational flaps.

❏ ❏

1. Remove the wing panel from the

building board. Use a T-bar with fresh 220 grit

sandpaper to blend away any unevenness from

the structure. Pay special attention to the trailing

edge of the wing. It's important to make the

trailing edge as straight as possible so the split

flaps will fit well.

15