Top Flite TOPA0130 User Manual

Page 22

❏ ❏

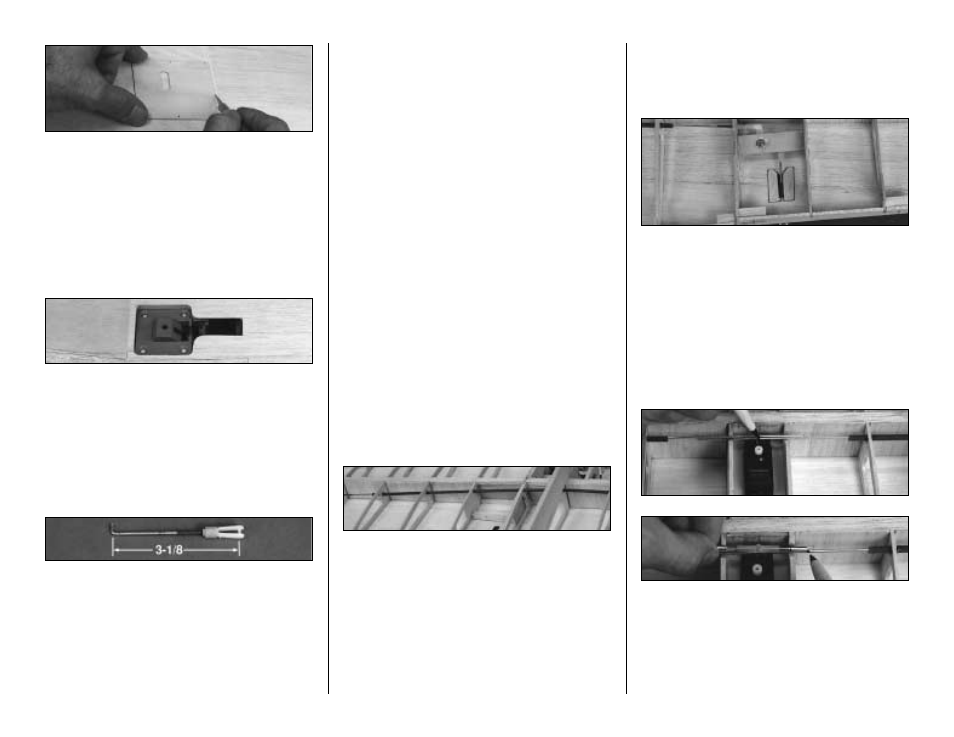

13. Rough cut the hatch openings on the

inside of your guide holes, then use a 1/16" ply

Hatch Cover to mark and cut the full size

opening.

Remember, it's faster to enlarge a hole

that's too small than to shrink one that's oversize.

❏ ❏

14. If you will be installing retracts,

remove enough mater ial to install the

mechanism and air cylinder, but leave final

fitting of the gear struts and wheels until later.

❏ ❏

15. Screw a Nylon Clevis onto a 4" Wire

Pushrod. The threaded por tion of the wire

should be flush with the inside edge of the

clevis. Make a 90 degree bend 3-1/8" from the

clevis pin. Cut off the excess wire, 1/4" past the

bend. Make a second pushrod in the

same manner.

❏ ❏

16. Insert the aileron pushrod through

the access hole in the skin and poke it through

the bellcrank from the top. Hint:

Use a 5/64"

drill bit to enlarge the hole where the aileron

pushrod will connect with the bellcrank. Attach

a Nylon Faslink to secure it in place. Repeat

this step for the other wing panel. If necessary,

hollow out a small indentation on the underside

of the ply to prevent the Faslink from catching.

❏ ❏

17. Cut the two 24" Plastic Outer

Pushrod Tubes to a length of 15-1/2". After

roughening the outer surface of the tubes with

sandpaper, push them through the 3/16" holes

that you drilled earlier during construction. Refer

to the plans for exact location, but generally they

run from W-2 to W-9. When positioned, spot

glue them to each rib with Medium CA.

❏ ❏

18. Screw a Nylon Clevis onto the

threaded ends of two 36" wire pushrods. As

before, the threads need to be into the clevis

about 1/4", or flush with the inside opening. Cut

the pushrods down to 22-1/2". Cut ten 3/16"

lengths of inner plastic pushrod tube, then slide

them onto the wire as shown on the plans. If they

are too loose, apply a drop of CA to secure them

in place. If too tight, cut them a little shorter.

Carefully inser t the pushrod wires into the

tubes from the W-11 ribs towards the center.

Hook-up the clevises to the bellcranks and

check for free movement.

❏ ❏

19. Position the aileron (outer) pushrod

clevis pin approximately 1/16" behind the TE

and tape it in position against the underside of

the wing. The bellcranks should be neutral.

Repeat this step for the other wing panel.

❏

20. Screw Threaded Brass Couplers all the

way into both ends of a Nylon Dual

Aileron Coupler.

❏

21. Hold the pushrods together at the center

of the wing and draw a line across both

pushrods at the center of the servo opening.

Hint:

It helps to drop a servo into position to

help with this alignment procedure. Hold the

Aileron Coupler on the pushrods with the Ball

22