Top Flite TOPA0130 User Manual

Page 39

❏

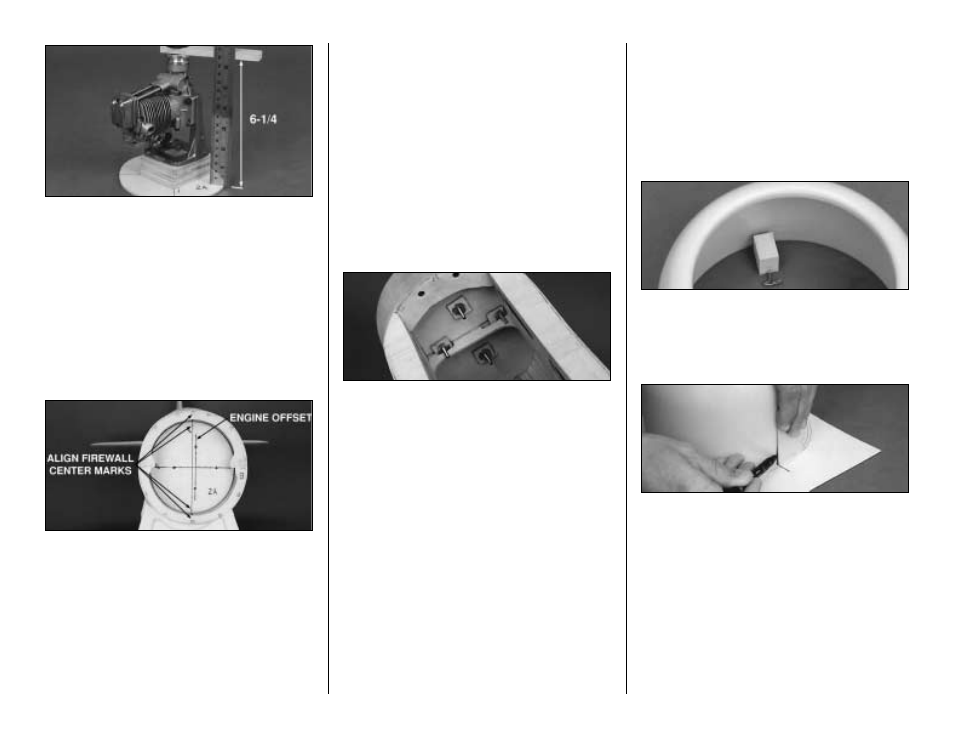

2. Bolt your engine to an engine mount, then

position it on the F-2A Firewall. Add plywood

shims, as required, to position the propeller

backplate 6-1/4" from the Firewall (this

applies to all engines).

❏

3. Glue the plywood shims together. Center

the engine mount on top of the shims and mark

the mounting hole locations. Center the mount on

F-2A using the offset line for horizontal alignment.

Drill the mounting holes with a 5/32" bit.

❏

4. Center F-2A on F-2B/F-2C. Use the

center joint between the formers and the two

punch mar ks on the top and bottom for

alignment. Note: When doing this alignment,

make sure that the Fuse is right-side-up and

that the offset line is to your right (or the

pilot’s left). Use the vertical centerline, not

the offset line, to align the Formers (refer to the

firewall drawing on the fuse plans).

❏

5. Hold F-2A in position, then mark the

mounting holes on F-2B/F-2C. Drill these holes

with an 11/64" bit to accommodate the blind

nuts. Check inside the fuse to see where the

holes are in relation to the blind nut cutouts on

the forward crutch. Enlarge the cutouts, if

necessar y, to accommodate the 1/8" ply

Firewall Backups.

See photo for step #7.

❏

6. Locate the four pre-cut 1/8" x 3/4" x 3/4"

Birch ply Firewall Backups. Drill an 11/64" hole

in the center of each. Insert the supplied 6-32

engine mount blind nuts into each ply Backup,

then gently seat them with a hammer.

❏

7. Insert the supplied 6-32 x 2-1/2" engine

mount screws through the mount, spacer shims,

and firewall to check the fit. Screw the blind nuts

onto the mounting screws from inside the fuse.

Glue the blind nut assemblies in position on the

inside of the firewall with CA.

Hint: work some

petroleum jelly into the threads to prevent any

stray glue from causing problems. Use a cut-off

wheel and Dremel tool to trim excess screw

length.

❏

8. Once the blind nuts are installed, remove

the engine mount assembly. Coat the back side

of F-2A with 30-minute epoxy, being careful to

stay at least 1/4" clear of the screw holes. Align

F-2A with F-2B/F-2C, then install the engine

mount with all four screws to

clamp F-2A in

position while the epoxy cures.

FIT THE COWL TO THE FUSE

❏

1. Make a simple tool to mark the inside of

the cowl by inserting a T-pin through a small

block of balsa, 3/16" above the work surface.

3/16" is the distance the cowl will extend over

the Fuse sheeting.

❏

2. Work on a flat surface. Hold the marking

tool with the point against the inside of the

cowl, then rotate the cowl to scribe an even

line around the inside circumference.

❏

3. Center the cowl over the Baffle Template,

then mark the four centerline positions around

the perimeter of the cowl. These four points will

be your mounting block locations.

❏

4. Measure and mark exactly 7/16" from the

rear edge of the cowl at each of the four points.

Hint: Use the same gadget that you made in

step #1, just reposition the T-pin to 7/16".

❏

5. Drill a 1/8" hole at each of these locations.

39