Top Flite TOPA0130 User Manual

Page 20

❏ ❏

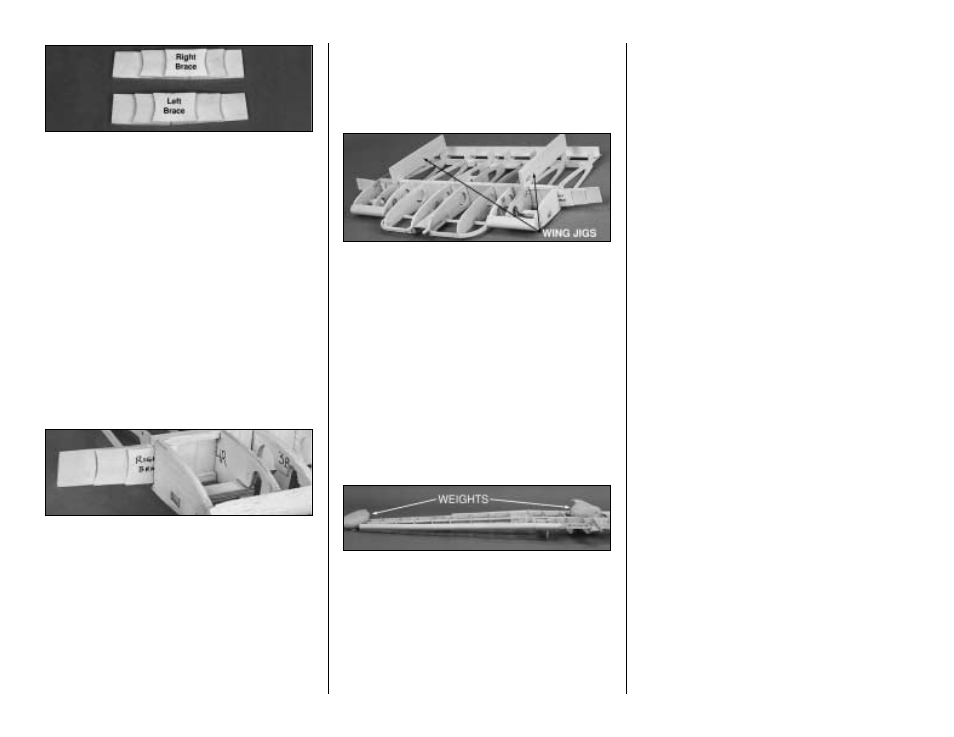

2. Without gluing, stack the three Braces

together and compare the assembly with the

drawing. Repeat this process with the second

set of braces,

but this time flip the pieces over

when you stack them. You should now have a

right hand and a left hand set of braces, as

shown in the photo.

Tracing around the edges of

the two shorter parts will help alignment when

you glue them together.

❏ ❏

3. When satisfied that the braces are

accurate, use 6 minute epoxy to glue the parts

together.

JOIN THE WING

❏ ❏

1. Carefully remove a 3/8" wide strip of

balsa between the spars on both W-5 and W-6

ribs. This will allow the Polyhedral Braces to be

inserted and glued between the spars.

❏ ❏

2. Test fit the Polyhedral braces into the

center and outboard wing panels, sanding if

necessary for a good fit. The wing panels should

mate evenly along the joint without any

unnecessary twisting or bending to line things up.

If you have to force the panels to fit, locate the

problem and fix it before proceeding. Any

twists will become a permanent part of the

structure after the panels are joined and will be

difficult to correct.

❏ ❏

3. Use only a spot of CA to glue the two

1/4" x 1-7/16 " x 7-1/2 " balsa Wing Jig Blocks

to the W-4 ribs. Glue the blocks to the W-4 jig

tabs and the top of the spar.

Now for the hard part, cleaning a space on your

work bench large enough to spread out and join

the wing.

IMPORTANT: Check your work surface with a

metal straightedge to make sure that it's

perfectly flat before proceeding. Make a "dry

run" of the following step before actually

performing it with glue.

❏ ❏

4. Place the Center panel on the Jig

Blocks in the middle of your work bench. Add

some weight to hold it in place (phone books or

small sandbags are handy for this). Prepare 1/2

ounce of 30 minute epoxy. Liberally apply the

epoxy to the W-6 Ribs and Polyhedral Braces.

Plug the Braces into the Outboard panels. Plug

the Outboard Wing Panels into the Center

section and align the Ribs for a flush fit.

Don't

worry about the exact alignment of the leading

edge. If you didn't glue the Leading Edges

exactly centered on the ribs they won't match.

After the wing is sheeted, the LE joints will be

blended with sandpaper. Once all the panels are

in position, clamp the ribs together and align the

Polyhedral Braces between the Spars as shown

on the top view of the plans. Put weights on the

two W-15 ribs to hold the jig tabs and Spars on

the work surface. Before the epoxy kicks off,

double check your work. Fill any gaps

between spars with 30 minute epoxy

SHEET THE BOTTOM OF THE

WING

Our suggested wing sheeting process allows

you to sheet the wing panels with one skin per

side. This technique is better than sheeting the

wing with individual sheets, and allows you to

pre-sand all of the seams that will be over

open structure.

All balsa sheeting will usually bend when it's cut

from the log since stresses are relieved. For the

best results, trim the edges of the wing sheeting

with a long metal straightedge and a sharp knife

before joining them.

NOTE: Do the following steps for

both the right and left wing panels.

❏

1. Sort through the remaining 1/16" x 3" x

30" balsa and pick out the 6 best sheets to be

used for the top surfaces of the outboard wing

panels. Pick out the 4 best 1/16" x 3" x 18"

sheets to use on the top of the center section.

❏

2. Lay waxed paper over a flat, smooth

work surface.

20